Combustion gas heating system of micro-negative pressure reaction kettle

A technology of gas heating and reactor, which is applied in heat treatment, preparation of liquid hydrocarbon mixture, fibrous filler, etc. It can solve the problems of excessive combustible gas, lower quality of carbon black, coking of equipment, etc., and achieve uniform flame distribution and high conversion efficiency , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited only to the examples.

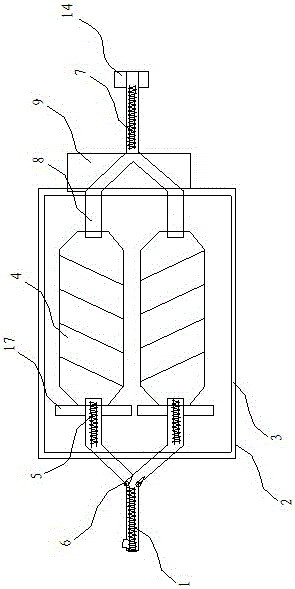

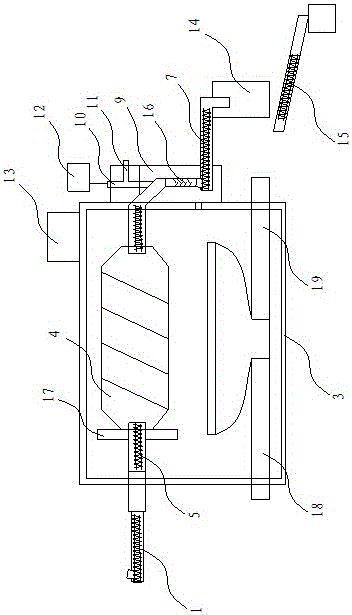

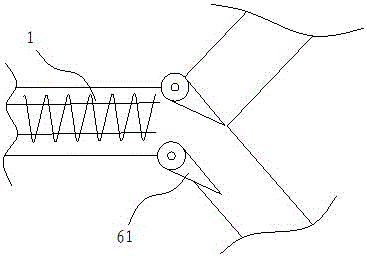

[0020] combine figure 1 and figure 2 As shown, a carbon black production device sequentially includes a feed system, a rotary cracking system, a discharge system, and a gas heating system. The rotary cracking system has a plurality of rotatable cracking furnaces 4, and the number of cracking furnaces 4 can be determined according to the actual situation, and can be multiple or one, preferably two. Divided into a plurality of cracking furnaces 4, the raw materials in each cracking furnace 4 are reduced in equal proportions, so as not to accumulate too much, and the heating is more uniform, so that the rubber block raw materials mixed in the middle can also be fully heated and cracked. One end of the cracking furnace 4 is provided with a driven gear 17, and the driven gears 17 on two adjacent cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com