Heat exchange unit and heat exchange reactor

A technology of heat exchange units and heat exchangers, applied in the direction of heat exchanger types, indirect heat exchangers, chemical/physical/physicochemical fixed reactors, etc., which can solve production safety accidents and heat extraction power cannot meet production needs And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

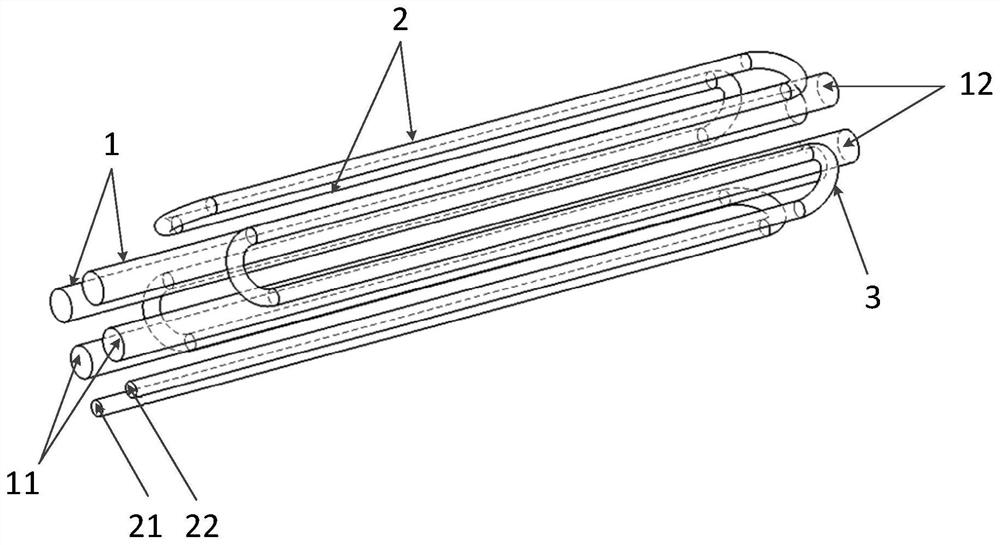

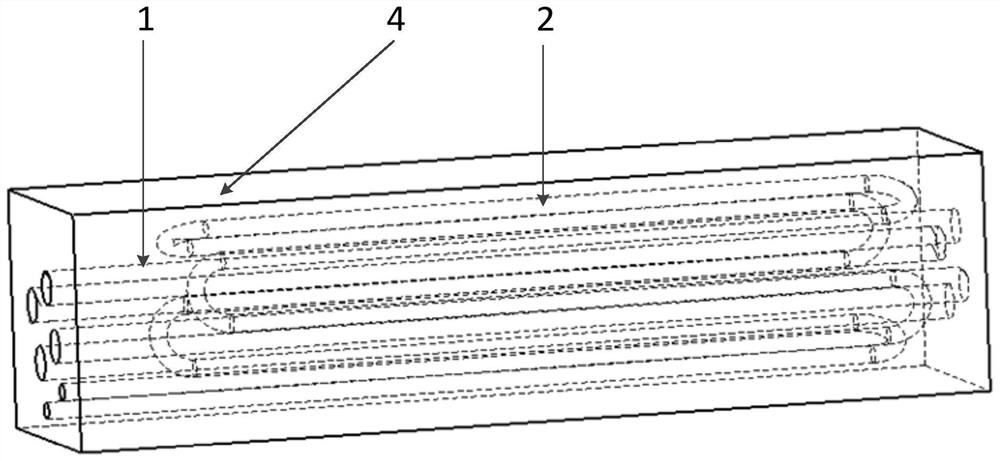

[0050] use as Figure 1-2 In the structure shown, silicon-aluminum alloy (with a silicon content of 15wt%) is used for the substrate and the heat exchange medium channel.

[0051] The heat exchange medium channel 1 and the reaction fluid channel 2 are respectively fixed in the base body 4, and the heat exchange medium channel is composed of 4 straight tubes; the reaction fluid channel is composed of 8 straight tubes, except for the reaction fluid inlet 21 and the reaction fluid outlet 22. The other nozzles are respectively connected to the adjacent reaction fluid channels end to end through the elbow section 3, so that 8 straight pipes form a complete coil tube, and the coil tubes are dispersed and wrapped around the heat exchange medium channels, wherein the adjacent reaction fluid channels The distance between 2 is 4-6 times the diameter of the reaction fluid channel, and the distance between the reaction fluid channel 2 and the adjacent heat exchange medium channel 1 is 2-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com