Wafer photoetching equipment

A lithography equipment and wafer technology, applied in the processing of photosensitive materials, etc., can solve the problems of wafer lithography failure and insufficient, and achieve the effect of rapid cleaning and speeding up the rotation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: Please refer to Figure 1-Figure 5 , the specific embodiments of the present invention are as follows:

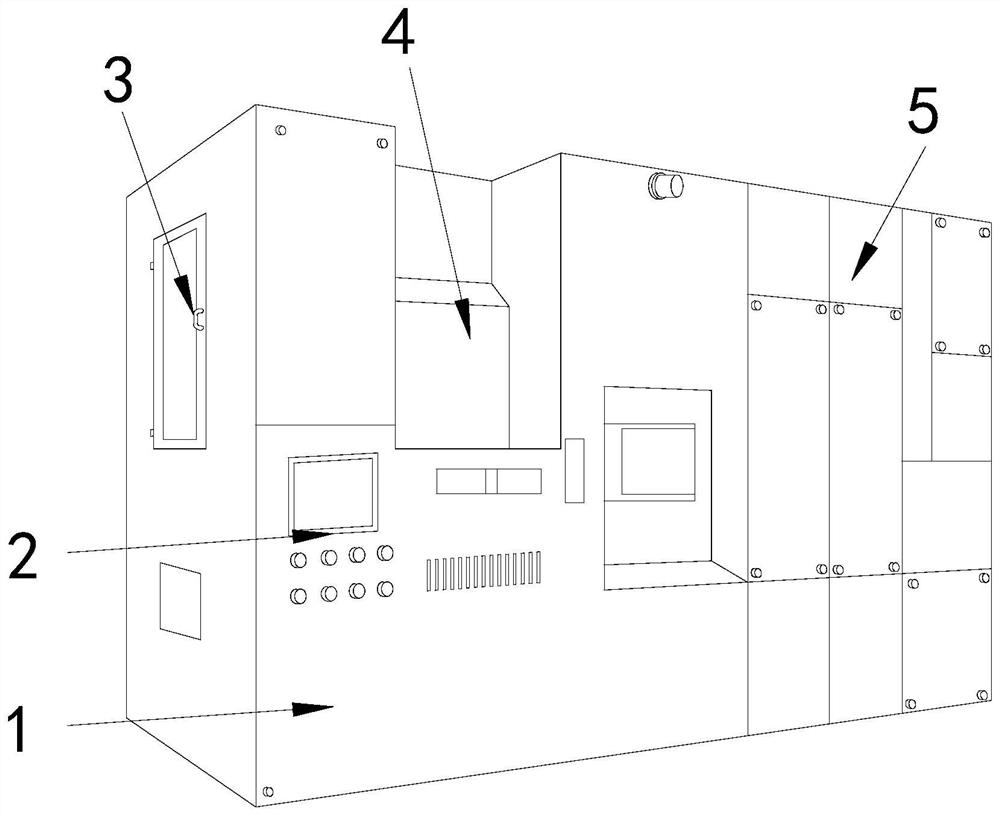

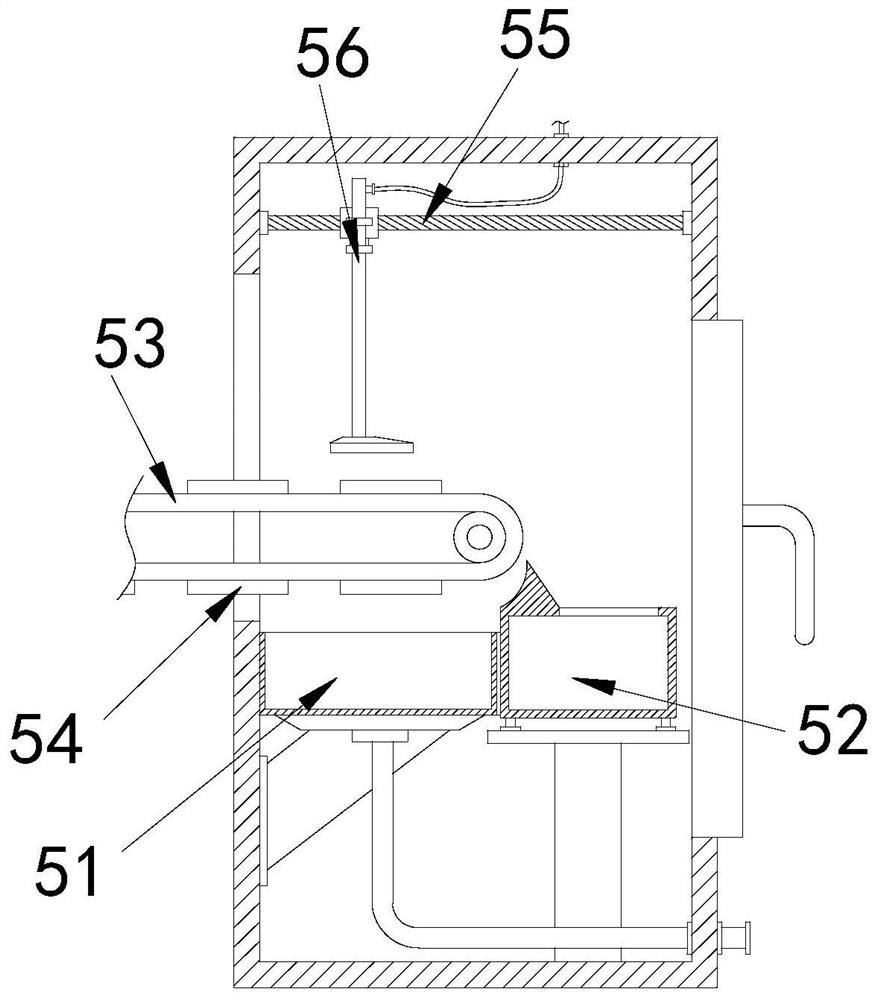

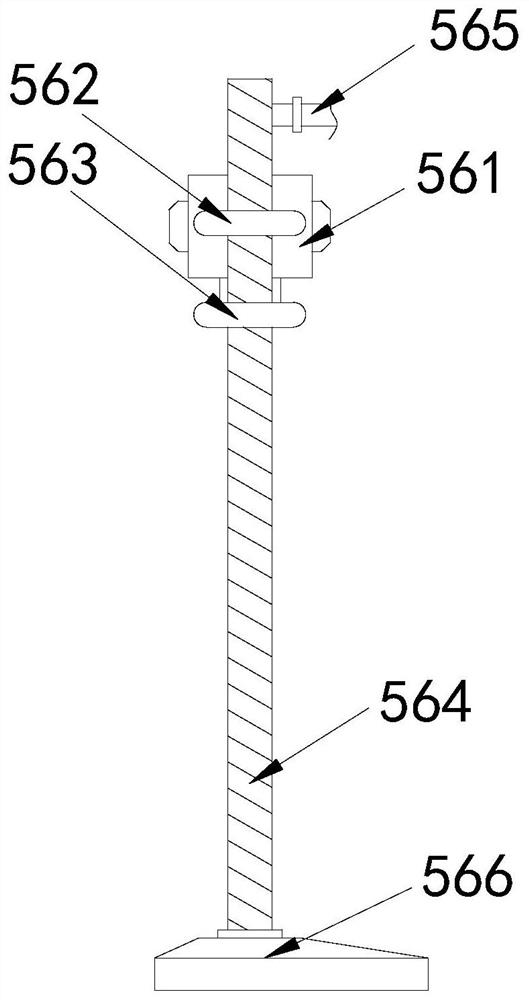

[0027] Its structure includes a main body 1, a control panel 2, a feed port 3, a photoresist block 4, and a developing device 5. The front end of the main body 1 is provided with a control panel 2, and the feed port 3 is arranged on the left side of the main body 1. The photoresist block 4 is located at one end of the main body 1, and the developing device 5 is arranged at the other end of the main body 1. The developing device 5 includes a photoresist recovery box 51, a wafer collection box 52, a conveyor belt 53, and a carrier plate 54 , a sliding rod 55, a material spraying device 56, the photoresist recovery box 51 is installed at one end of the bottom of the developing device 5, the wafer collection box 52 is installed at the other end of the bottom of the developing device 5, and the conveyor belt 53 is arranged on Just above the photoresist recover...

Embodiment 2

[0032] Example 2: Please refer to Figure 6-Figure 8 , the specific embodiments of the present invention are as follows:

[0033]The material blocking device a51 includes a carrier b1, a material blocking plate b2, a collecting tank b3, a cover plate b4, and a discharge head b5. The carrier b1 is cylindrical, and the material blocking plate b2 is provided with four uniform Arranged around the carrier b1, the collection tank b3 is set inside the material baffle b2, the cover plate b4 is engaged on the upper end of the collection tank b3, and the discharge head b5 is installed at the end of the collection tank b3 , the length of the cover plate b4 is shorter than the length of the collecting tank b3, which is beneficial to the removal and installation of the cover plate b4 in the collecting tank b3.

[0034] The cover plate b4 includes a collection hole b41, a feed head b42, a mounting groove b43, a return spring b44, and a block b45. There are more than five collection holes b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com