Preparation method of grease type feed

A technology of oil and feed, which is applied in the field of preparation of oil-based feed, can solve the problems of complex processing methods, uneven nutritional components of oil-based feed, and affecting the health and growth of poultry, so as to improve feed energy concentration, maximize efficiency, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

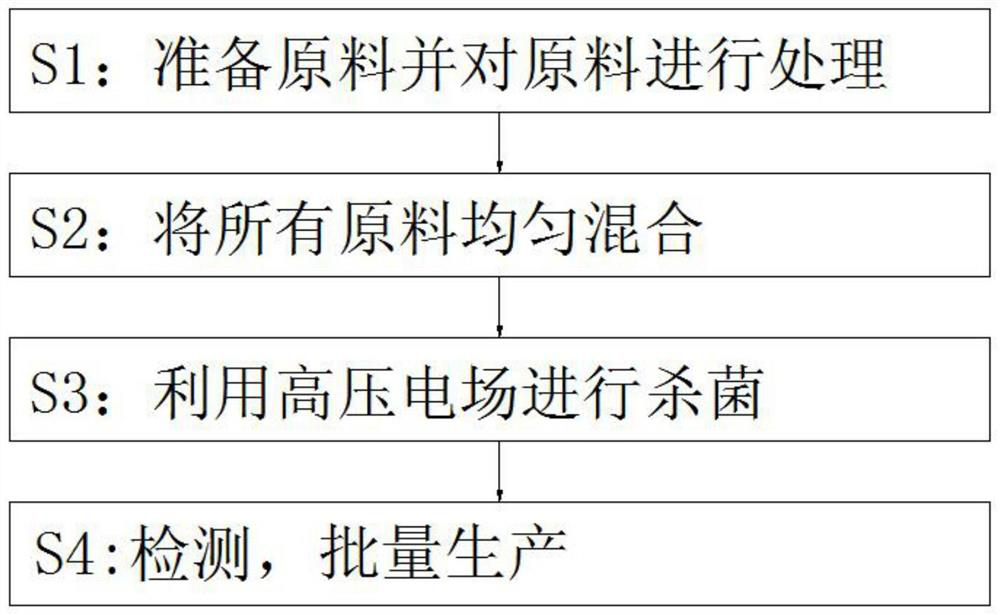

[0032] refer to figure 1 , a method for preparing an oil-based feed, comprising the following preparation steps:

[0033] S1: Prepare and process raw materials;

[0034] S2: Mix all raw materials evenly;

[0035] S3: use high-voltage electric field to sterilize;

[0036] S4: Testing, mass production.

[0037] In this example, 3 parts of animal oil components, 4 parts of vegetable oil components, 0.01 parts of nutritional components, 0.1 parts of traditional Chinese medicine antibody components, 26 parts of basic components, 0.005 parts of sodium benzoate, 3 parts of water, and 0.1 parts of emulsifier were prepared in S1.

[0038] In this example, the animal fat components include chicken fat and fish fat, wherein the ratio of chicken fat and fish fat is 1:0.8, the chicken fat and fish fat are pulverized by a pulverizer, and then the pulverized animal fat is added into the mixer Boil, and add an appropriate amount of water, at 90°C, boil for 40 minutes, and keep stirring un...

Embodiment 2

[0050] refer to figure 1 , a method for preparing an oil-based feed, comprising the following preparation steps:

[0051] S1: Prepare and process raw materials;

[0052] S2: Mix all raw materials evenly;

[0053] S3: use high-voltage electric field to sterilize;

[0054] S4: Testing, mass production.

[0055] In this example, 5 parts of animal oil components, 6 parts of vegetable oil components, 0.015 parts of nutritional components, 0.2 parts of traditional Chinese medicine antibody components, 28 parts of basic components, 0.01 parts of sodium benzoate, 5 parts of water, and 0.2 parts of emulsifier were prepared in S1.

[0056] In this example, the animal fat components include chicken fat and fish fat, wherein the ratio of chicken fat and fish fat is 1:0.8, the chicken fat and fish fat are pulverized by a pulverizer, and then the pulverized animal fat is added into the mixer Boil, and add an appropriate amount of water, at 92°C, boil for 50 minutes, and keep stirring un...

Embodiment 3

[0068] refer to figure 1 , a method for preparing an oil-based feed, comprising the following preparation steps:

[0069] S1: Prepare and process raw materials;

[0070] S2: Mix all raw materials evenly;

[0071] S3: use high-voltage electric field to sterilize;

[0072] S4: Testing, mass production.

[0073] In this example, the animal fat components include chicken fat and fish fat, wherein the ratio of chicken fat and fish fat is 1:0.8, the chicken fat and fish fat are pulverized by a pulverizer, and then the pulverized animal fat is added into the mixer Boil, and add an appropriate amount of water, at 95°C, boil for 60 minutes, and keep stirring until a viscous liquid is prepared, and store it in an insulated tube for later use.

[0074] In this embodiment, the vegetable oil components include wheat germ oil, linseed oil, soybean oil, rapeseed oil and corn oil, wherein the ratio of wheat germ oil, linseed oil, soybean oil, rapeseed oil and corn oil is 1:0.8:1.5: 1.2:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com