Heat exchanger structure optimization method based on hot melt gas-liquid two-phase heat transfer structure

A technology of heat exchange structure and optimization method, which is applied in design optimization/simulation, instrument, calculation, etc., to achieve the effects of high coordination, improved material utilization, and novel production methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] XL=x-bCos[(x / 2)^2]

[0052] YL=y-bCos[(y / 2)^2]

[0054] p1=ContourPlot3D[Cos[XL]Sin[YL]+

[0055]Con[YL]Sin[ZL]+Cos[ZL]Sin[XL]=0,

[0056] {x,-Pi,Pi},{y,-Pi,Pi},{z,-Pi,Pi}]

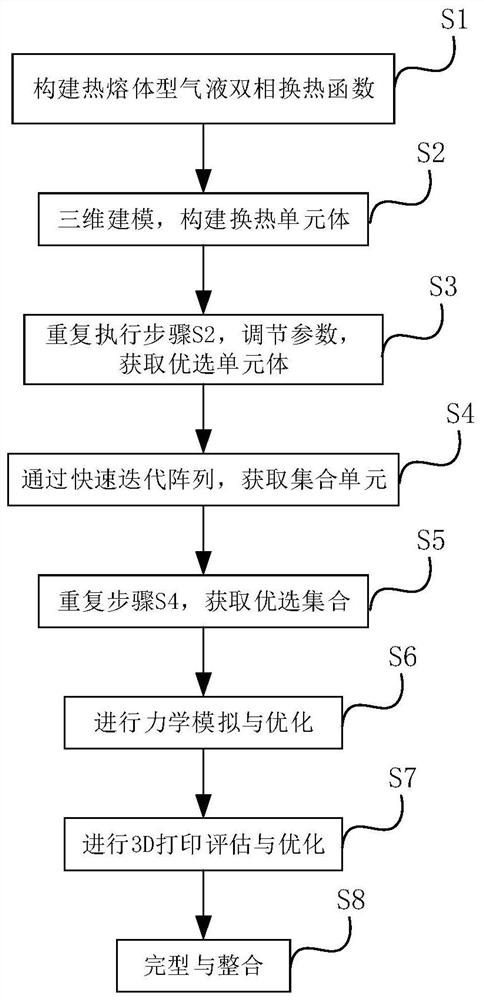

[0072] The iterative principle and structural principle of the heat exchanger structure optimization method of the present embodiment will be described in detail below.

[0075] The gas-liquid ratio parameter monomer unit cell model required to meet the target is adjusted by the parameters, and then through the fast iteration matrix

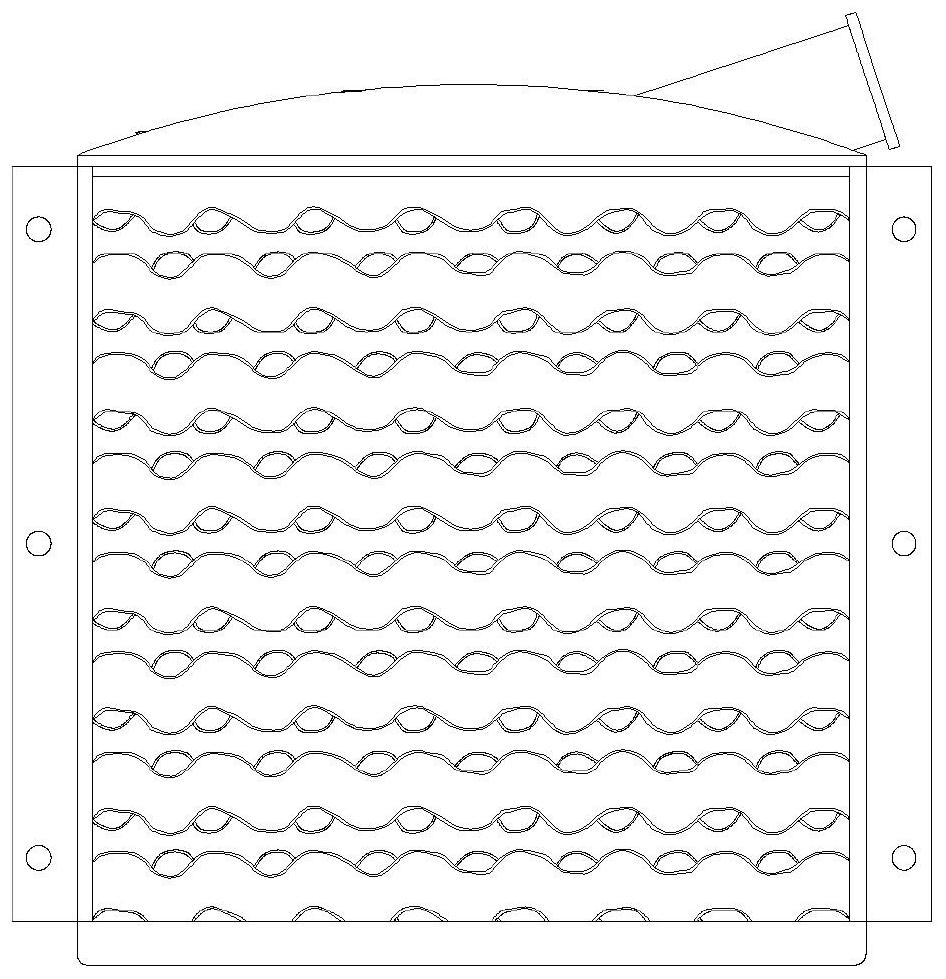

[0084] The wall thickness of the heat exchanger structure designed in this embodiment is 0.3mm, and the edge length of the unit body is 0.425*pi (mm), similar to

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com