High-frequency inverter power supply with heat dissipation function

A technology of high-frequency inverter and inverter power supply, which is applied in the direction of output power conversion device, AC power input conversion to DC power output, electrical components, etc. It can solve the problem of a large amount of dust accumulation and the high-frequency inverter does not have active heat dissipation Function, overheating air inlet and other problems, to achieve the effect of convenient and fast cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

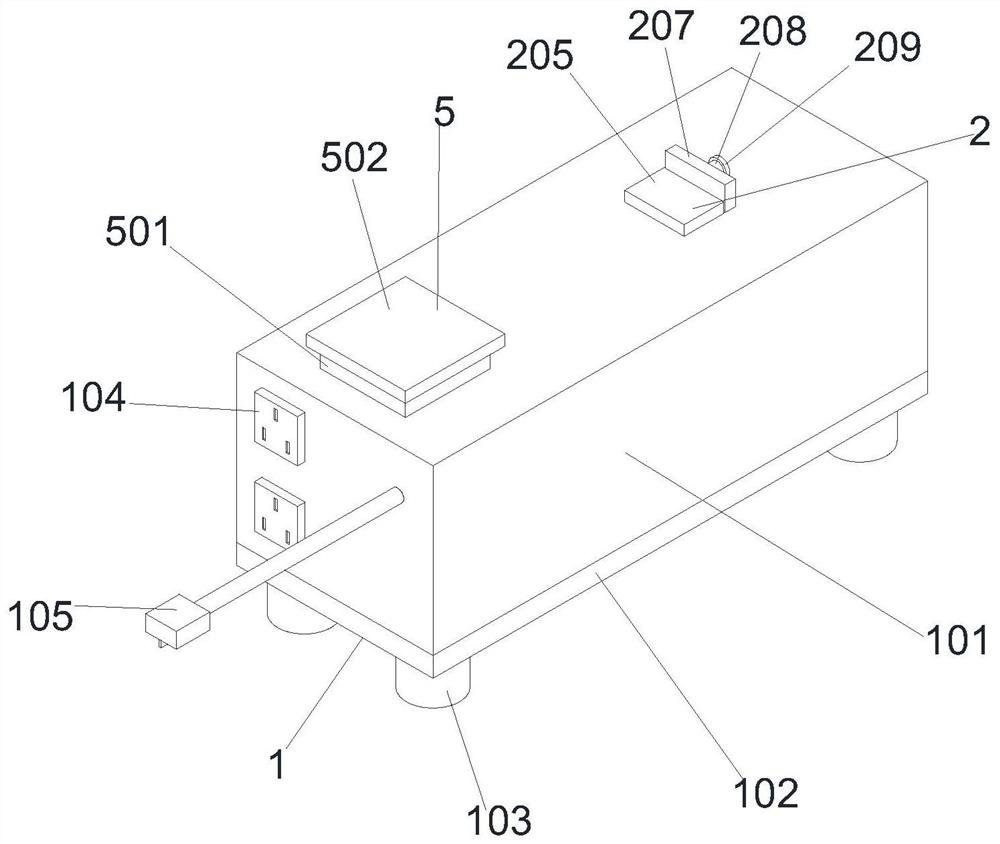

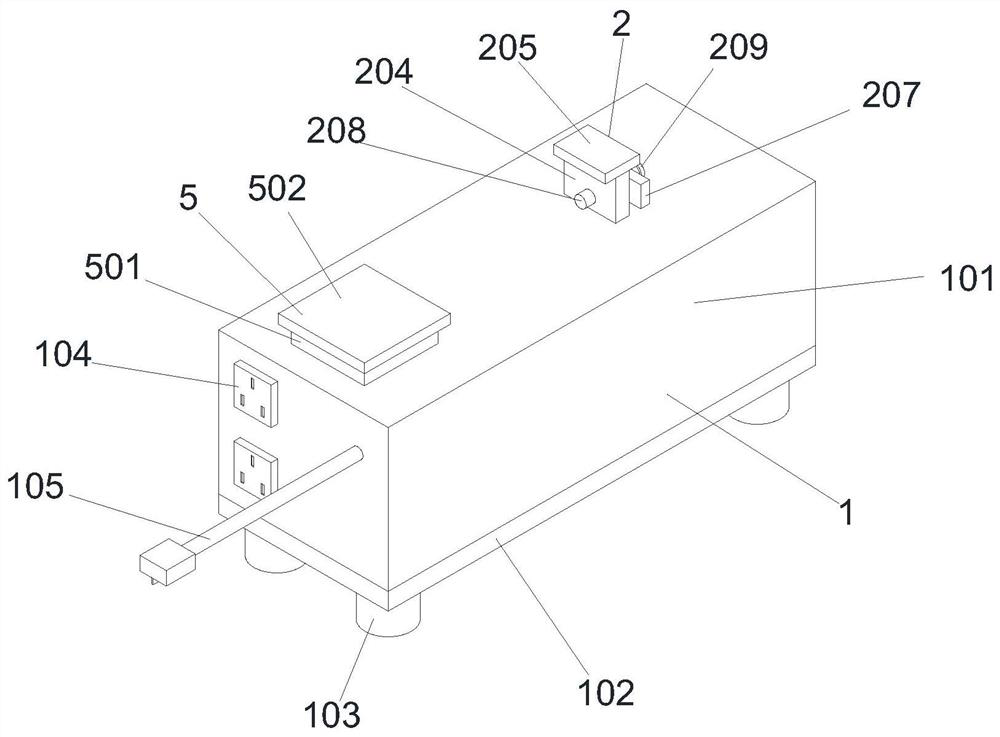

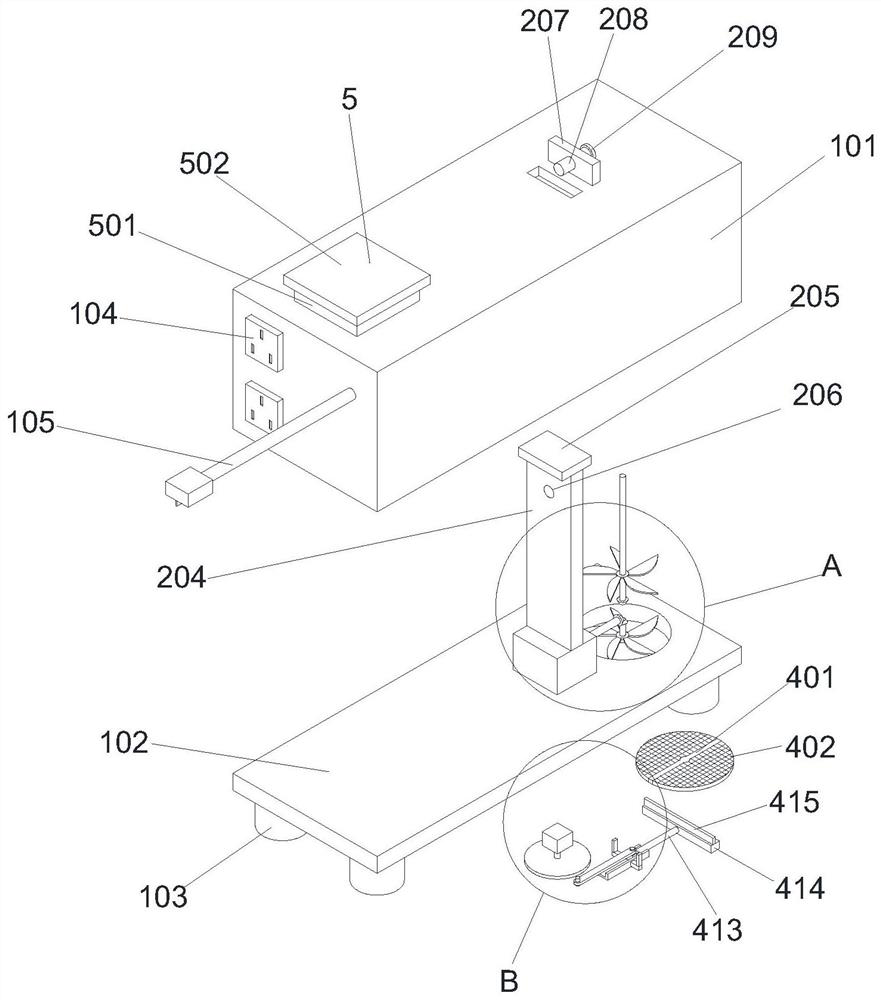

[0029] refer to figure 1 , figure 2 with image 3, a high-frequency inverter power supply with heat dissipation function, including an inverter power supply 1, the inverter power supply 1 includes a power supply casing 101, the lower surface of the power supply casing 101 is fixedly connected with a casing bottom plate 102, and the four corners of the lower surface of the casing bottom plate 102 are fixedly connected There are supporting legs 103, the rear end of the left side of the power supply housing 101 is fixedly connected with an output socket 104, the front end of the left side of the power supply housing 101 is fixedly connected with an input plug 105, and the right end of the upper surface of the housing bottom plate 102 is provided with an air inlet 106 , the inside of the power supply housing 101 is provided with a drive switching device 2 and an air inlet and outlet device 3, a heat dissipation dredging device 4 is provided below the housing bottom plate 102, an...

Embodiment 2

[0032] refer to Figure 1-4 , a high-frequency inverter power supply with a heat dissipation function, which is basically the same as that of Embodiment 1, and furthermore, the difference is that the driving device includes a motor one 201, and the lower surface of the motor one 201 is attached to the upper surface of the shell bottom plate 102 On the surface, the right side of the rotating shaft of motor one 201 is fixedly connected with connecting shaft one 202, the right side of connecting shaft one 202 is fixedly connected with bevel gear one 203, and the upper surface of motor one 201 is fixedly connected with connecting plate 204, connecting plate The upper surface of 204 is fixedly connected with a top plate 205, and the upper end of the left and right sides of the connecting plate 204 is penetrated with a card hole 206, and the front, rear, left, and right sides of the connecting plate 204 are penetrated and slidably connected to the upper side plate of the power supply...

Embodiment 3

[0035] refer to Figure 3-4 , a high-frequency inverter power supply with heat dissipation function, which is basically the same as Embodiment 1, and further, the difference is that the air suction device includes a bevel gear 2 301, and the bevel gear 2 301 meshes with the bevel gear 1 203, the lower surface of bevel gear 2 301 is fixedly connected with connecting shaft 2 302, the circumferential side of connecting shaft 2 302 is fixedly connected with fixed ring 1 303, and the circumferential side of fixed ring 1 303 is fixedly connected with fan piece 1 304. The wind device includes a bevel gear 3 305, the bevel gear 3 305 meshes with the bevel gear 1 203, the upper surface of the bevel gear 3 305 is fixedly connected with the connecting shaft 3 306, and the upper surface of the connecting shaft 3 306 is connected to the power supply shell through bearing rotation 101, the inner wall of the upper side plate, the circumferential side of the connecting shaft 3 306 runs throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com