Load-force-independent triggering device

A technology of triggering device and load force, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problem of not being suitable for remote triggering of triggering devices, and achieve the effect of avoiding vertical displacement and increasing triggering reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

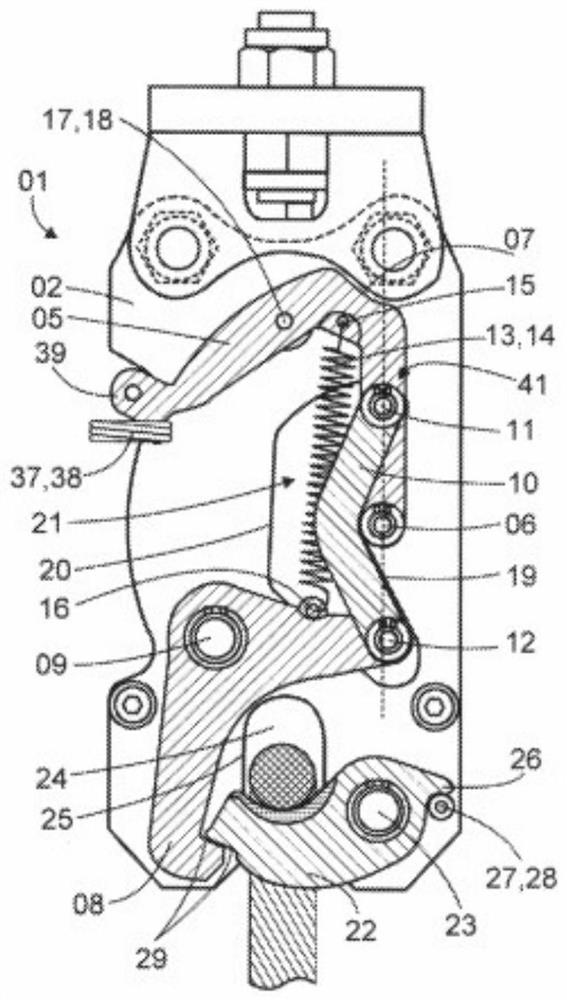

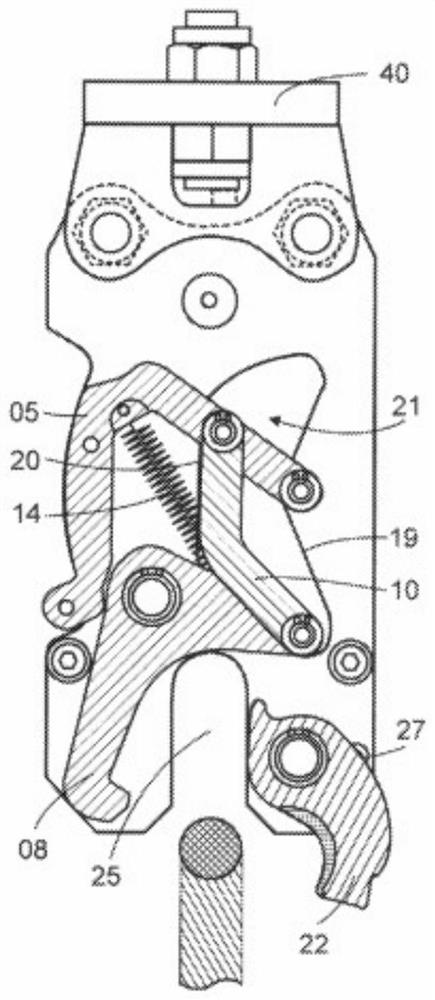

[0062] figure 1 A load-force-independent triggering device 01 for underwater applications is shown. Therefore, the materials used are resistant to sea water. The triggering device 01 is in a closed position in which a load, eg an OFOS (Ocean Ocean Observation System) in a lowered frame is held eg on a crane on a research vessel. The weight of the OFOS and the drop frame is several hundred kilograms, they act on the trigger 01 as a whole, and not on the immediate trigger area. Instead, the force is guided along it by the triggering device 01 . Thus, by applying only a low level of trigger force, it is possible to trigger the trigger device 01 independently of the applied load force.

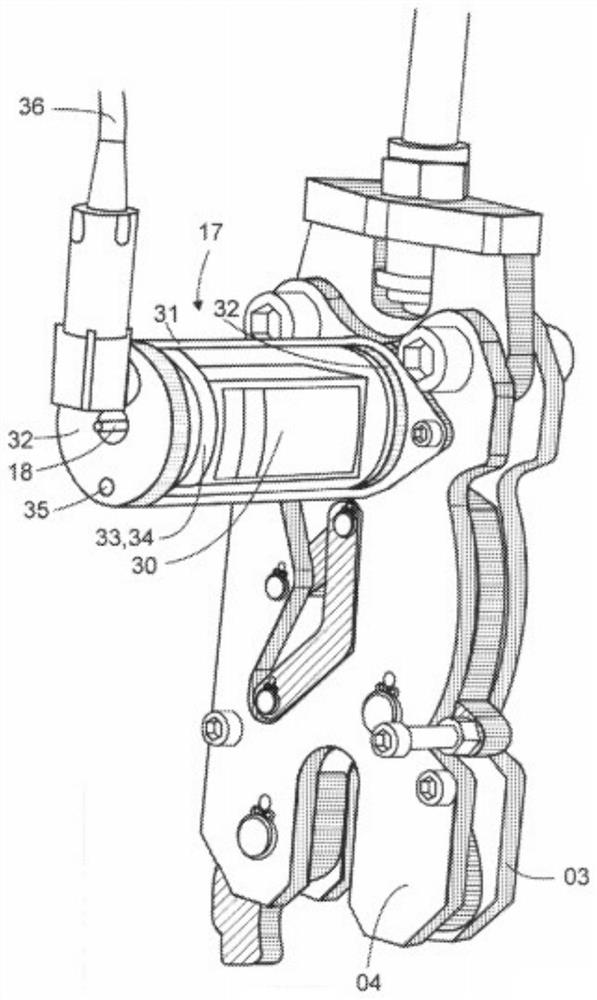

[0063] The triggering device 01 comprises a housing 02, which in the exemplary embodiment shown consists of two structured steel plates 03, 04 (cf. image 3 ) screw together. This has the advantage that in particular movable parts can be arranged between the two steel plates 03 , 04 and thus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com