Cloth bag dust removal equipment convenient to clean

A technology of bag dust removal and equipment, applied in the field of air purification, can solve the problems of time-consuming and laborious manual cleaning, inconvenient cleaning of bag dust collectors, etc., achieve thorough cleaning, solve the inconvenience of cleaning, and save workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

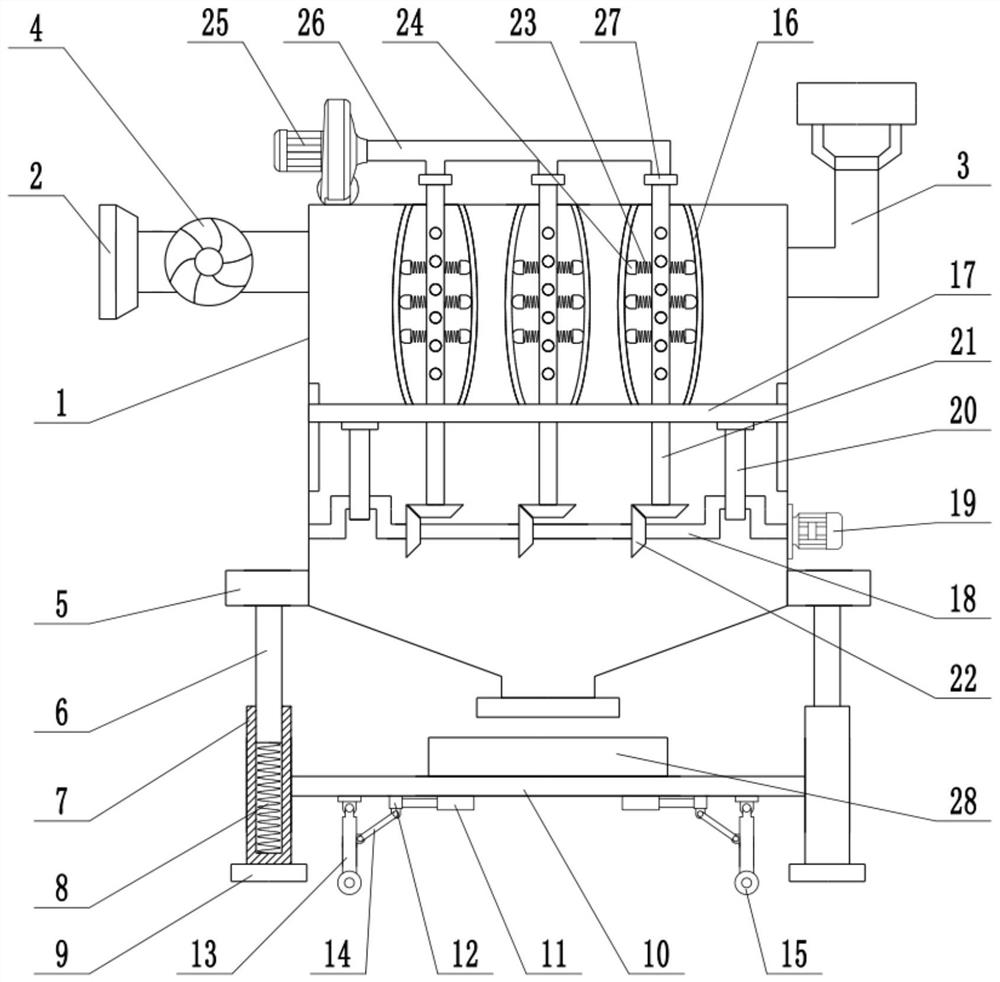

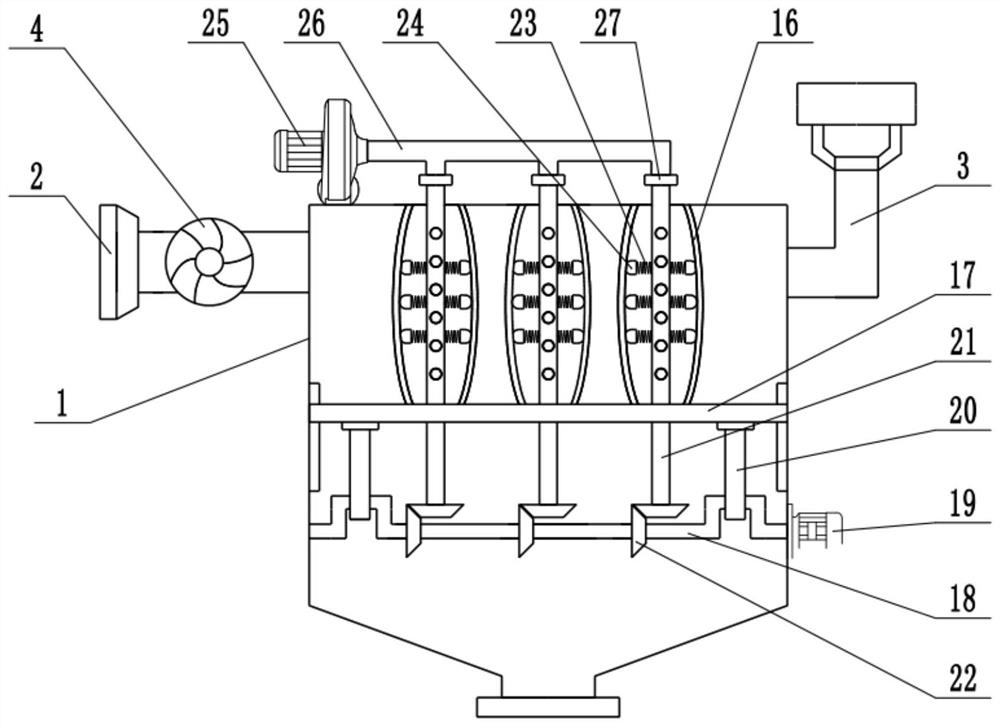

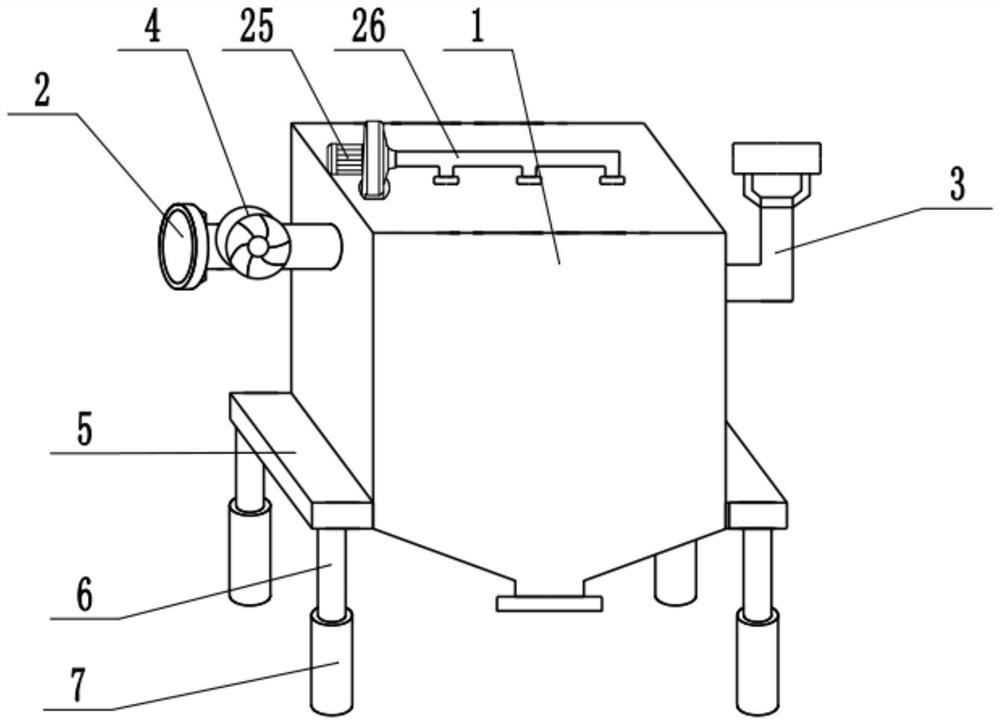

[0023] see Figure 1-3 , in an embodiment of the present invention, a bag dust removal device that is easy to clean includes a housing 1, an air inlet 2, an air outlet 3 and a bag assembly 16, the left side wall of the housing 1 is equipped with an air inlet 2, and the air inlet A fan 4 is installed on the 2, and the dust-containing gas can be transported into the casing 1 by the fan 4, and an exhaust port 3 is installed on the right side wall of the casing 1, and the dust-containing gas after treatment can be discharged through the exhaust port 3, and the casing The left and right sides of 1 are respectively fixedly connected with a mounting plate 5, the lower surface of the mounting plate 5 is fixedly connected with a support rod 6, the lower end of the support rod 6 is provided with a sleeve 7, the support rod 6 is slidingly connected with the sleeve 7, and the sleeve The inside of 7 is equipped with shock absorbing spring 8, utilizes shock absorbing spring 8 to play the ef...

Embodiment 2

[0025] On the basis of Embodiment 1, a moving mechanism is installed on the lower surface of the fixed plate 10, and the moving mechanism includes a telescopic mechanism 11, a slide block 12, a movable rod 13, a connecting rod 14 and a universal wheel 15, and the bottom of the fixed plate 10 is fixedly connected There is a telescopic mechanism 11, the telescopic mechanism 11 is an electro-hydraulic telescopic cylinder, the extended end of the telescopic mechanism 11 is fixedly connected with a slider 12, and the slider 12 is slidably connected with the bottom of the fixed plate 10, and the lower surface of the fixed plate 10 is hinged with a movable rod 13. The lower end of the movable rod 13 is equipped with a universal wheel 15, and the lower surface of the slider 12 is hinged with a connecting rod 14, and the lower end of the connecting rod 14 is hinged with the middle part of the movable rod 13 to control the extension of the telescopic mechanism 11 and drive the slider 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com