Yarn detector assembly

A wire detector and component technology, which is applied in the direction of conveying filamentous materials, thin material processing, transportation and packaging, etc., can solve problems such as breakage, poor integration, and high yarn tension, so as to increase detection accuracy and reduce production cost, the effect of simplifying the assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

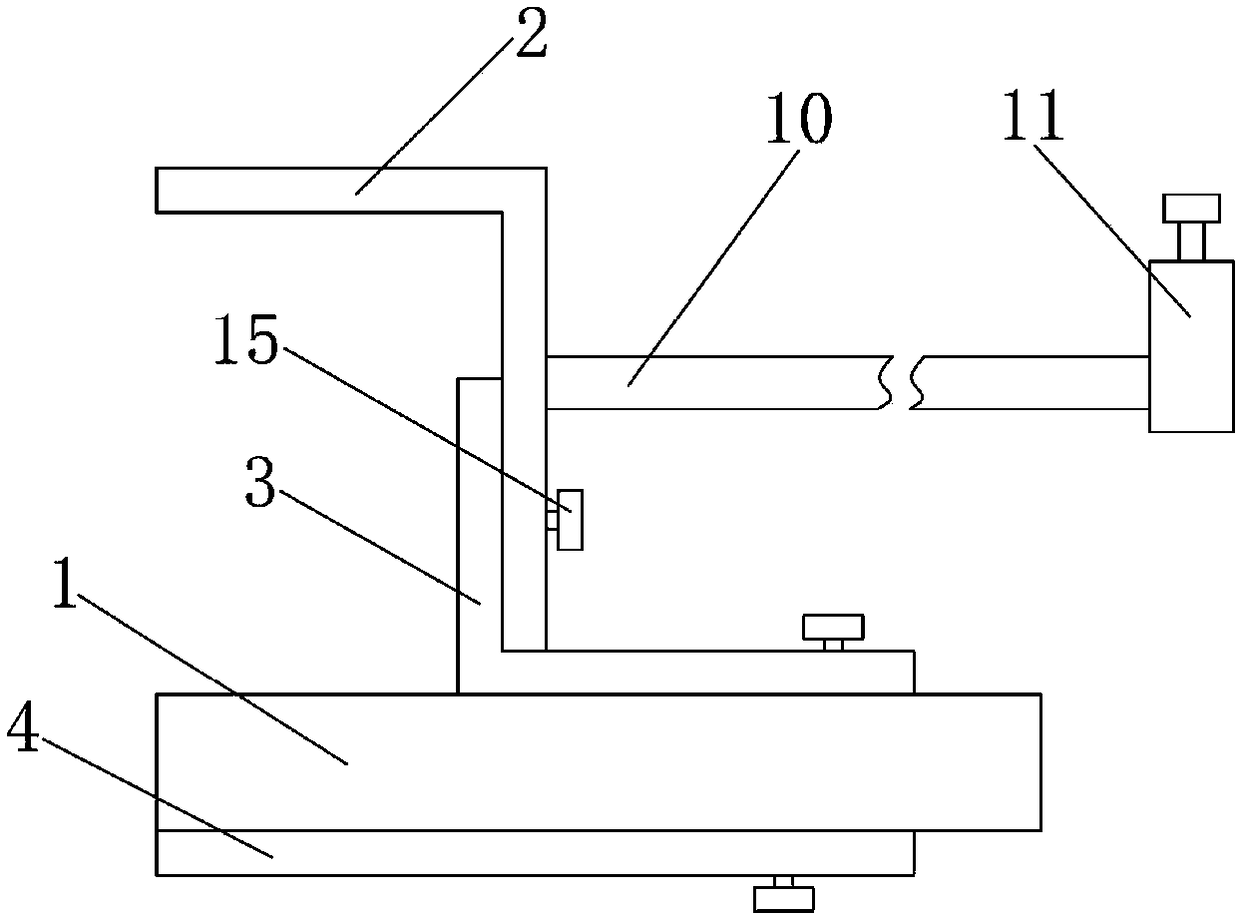

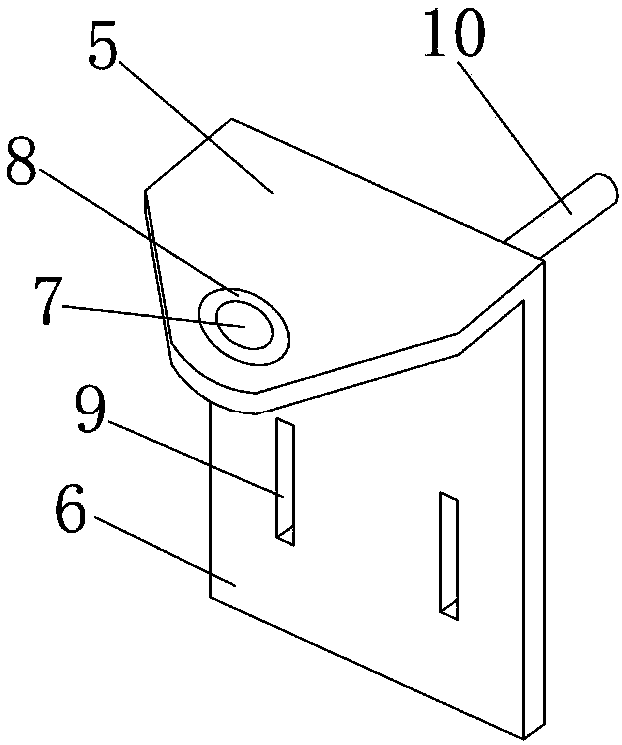

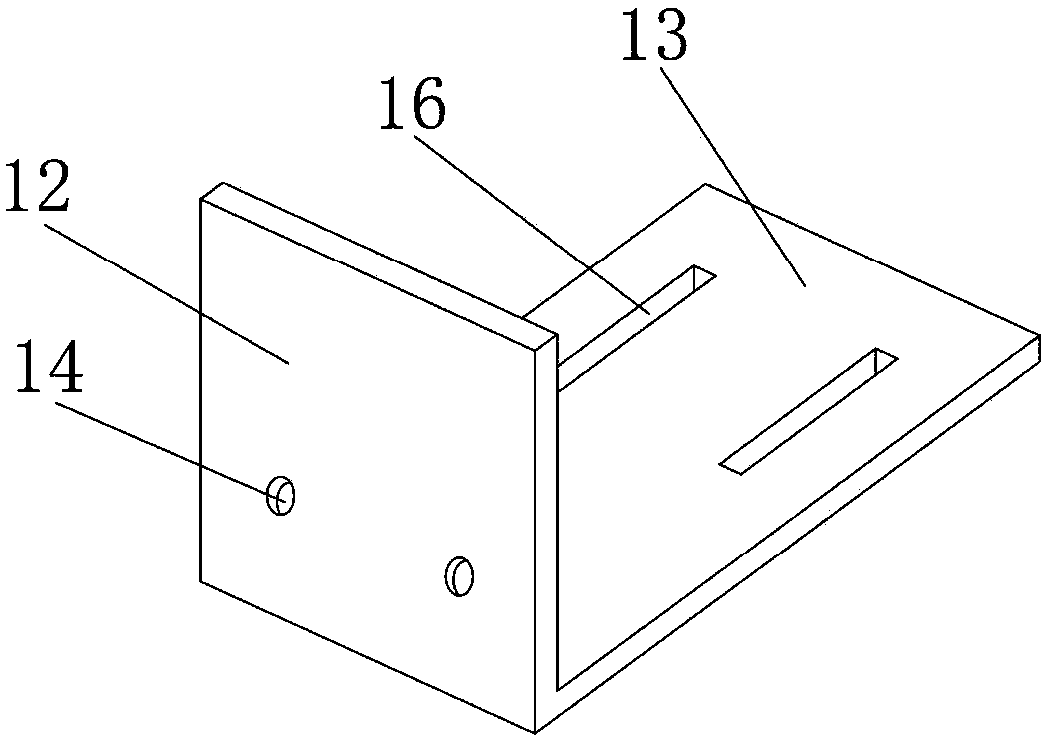

[0024] Embodiment: a kind of thread finder assembly, as Figure 1-Figure 9 As shown, it includes a thread finder, a first iron piece, a second iron piece and a third iron piece. The first iron piece is in an inverted “L” shape and includes a fan-shaped segment and a first vertical segment. The fan-shaped The end of the segment is provided with a first wire-passing hole, and an annular rubber ring is provided on the first wire-passing hole, and a first strip-shaped hole is provided on both sides of the first vertical section, and the first strip-shaped hole Above the first vertical section, a support rod is fixedly welded on the first vertical section, and the other end of the support rod is provided with a clamping device; the second iron sheet is "L"-shaped, including the second vertical section and the transverse Section, both sides of the second vertical section are provided with first bolt holes, when the second vertical section and the first vertical section are in contac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com