Atomization spray disc and method for preparing narrow particle size alloy powder for additive manufacturing by gas atomization

A technology of alloy powder and atomization spraying, which is applied in the fields of additive processing, metal processing equipment, transportation and packaging, etc., can solve the problem of low yield of alloy powder, etc., and achieve high practicability, cost reduction, simple and convenient sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A method for preparing alloy powder with narrow particle size for additive manufacturing based on entropy reduction control, comprising the following steps:

[0056] (1) Alloy smelting: Put the GH4169 nickel-based alloy bar in the melting chamber for vacuum electrode induction melting. The melting temperature is 1520°C. By controlling the heating of the induction coil, the lower end of the bar is gradually melted to form a continuous and stable metal melt. The superheat of the melt is 200°C, and the flow rate of the alloy melt is 6kg / min.

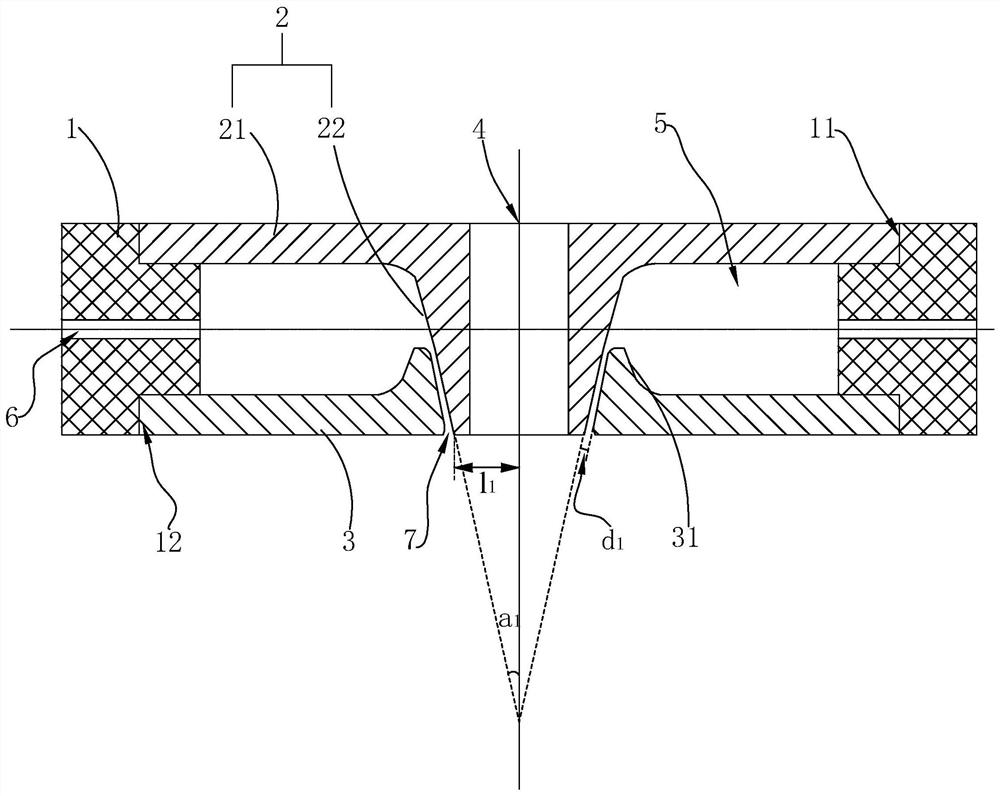

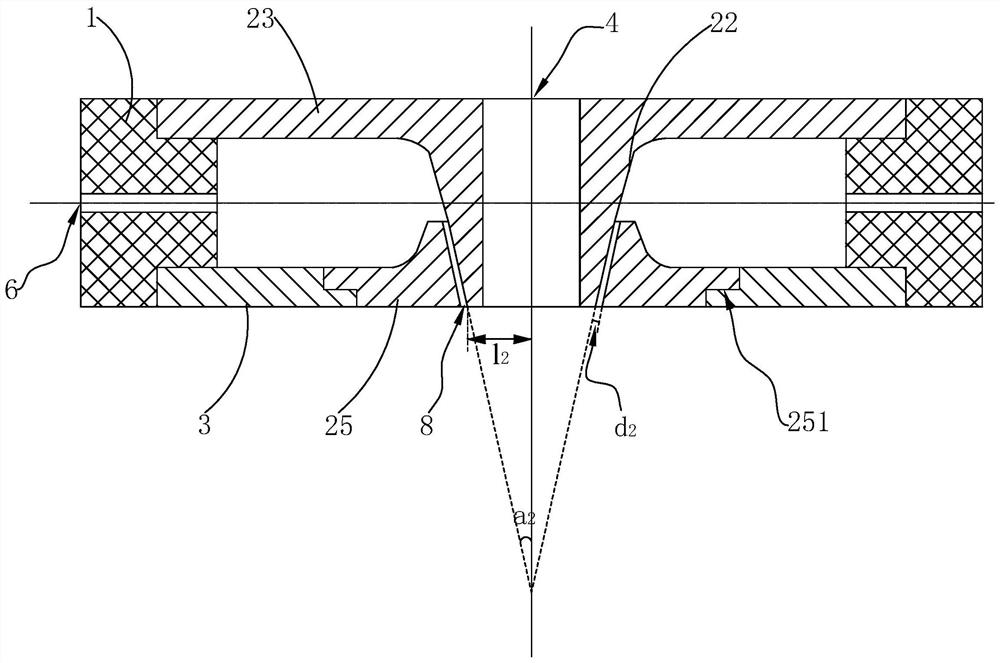

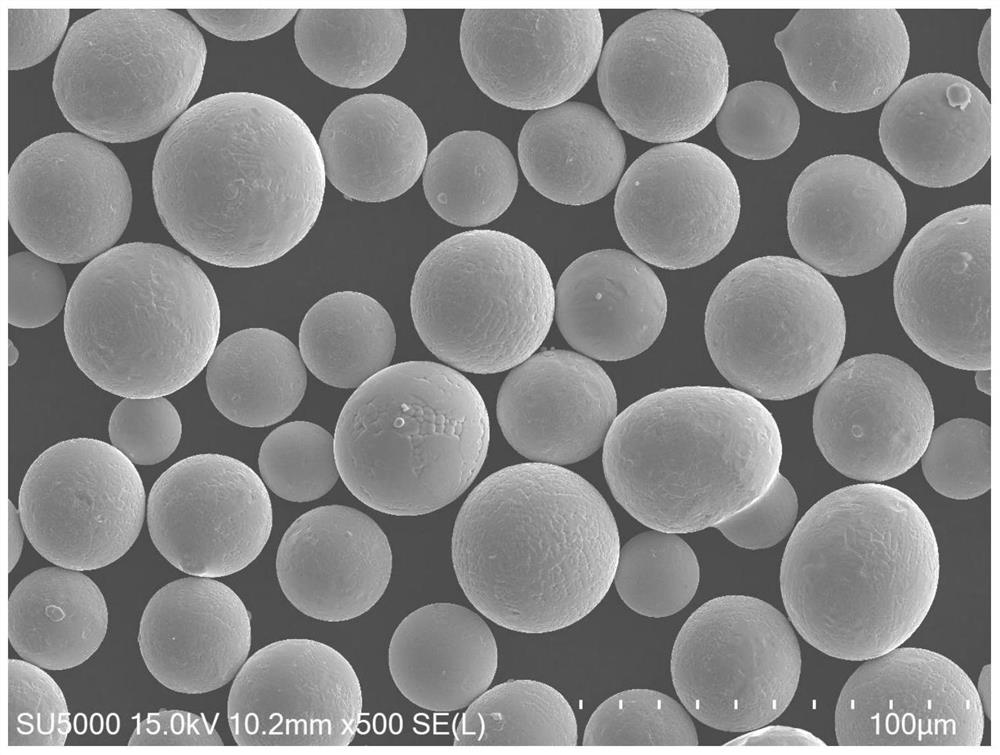

[0057] (2) Atomized pulverization: According to the target particle size requirements of the alloy powder with a median particle size of 30 μm and a particle size distribution range of 15-53 μm for the selective laser melting technology, the annular seam atomization spray plate is selected, and the annular seam width is d 1 0.8mm, jet angle α 1 is 30°, and the center-to-center distance L at the lower end of the circular seam 1 14mm...

Embodiment 2-19

[0060] The difference between Examples 2-19 and Example 1 lies in the selection of alloy raw materials, different spray pans, different spray pan structural parameters and different atomization process parameters when preparing alloy powders. See Table 1 for details.

[0061] Equipment and process conditions for preparing alloy powders of table 1 embodiment 1-19

[0062]

[0063] Among them, the alloys used in Examples 1-2 and Examples 4-15 are commercially available; the superalloy melts are obtained by melting master alloy rods. The specific composition and ratio of the NiCrAlY alloy in embodiment 3 and embodiment 17 are: Ni is the balance, Cr: 23%, Al: 8%, Y: 0.8%; The FeNiCr alloy of embodiment 16 is the metal iron, nickel Raw materials such as chromium, niobium and the like are added into the melting crucible according to the alloy ratio and smelted to obtain the FeNiCr stainless steel alloy melt, the alloy composition ratio is: Ni: 3%, Cr: 16%, and Fe is the balance; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com