Automatically-controlled turning plate rubber dam

A flap and rubber technology, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve the problems that cannot be adjusted according to actual needs, can not be adjusted well, cannot meet actual needs, etc., to ensure durability and The effect of water storage quality, reduction of working hours, and increase of economic benefits of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions in the embodiments of the present invention will be clearly and completely described below. The embodiments of the present invention and all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

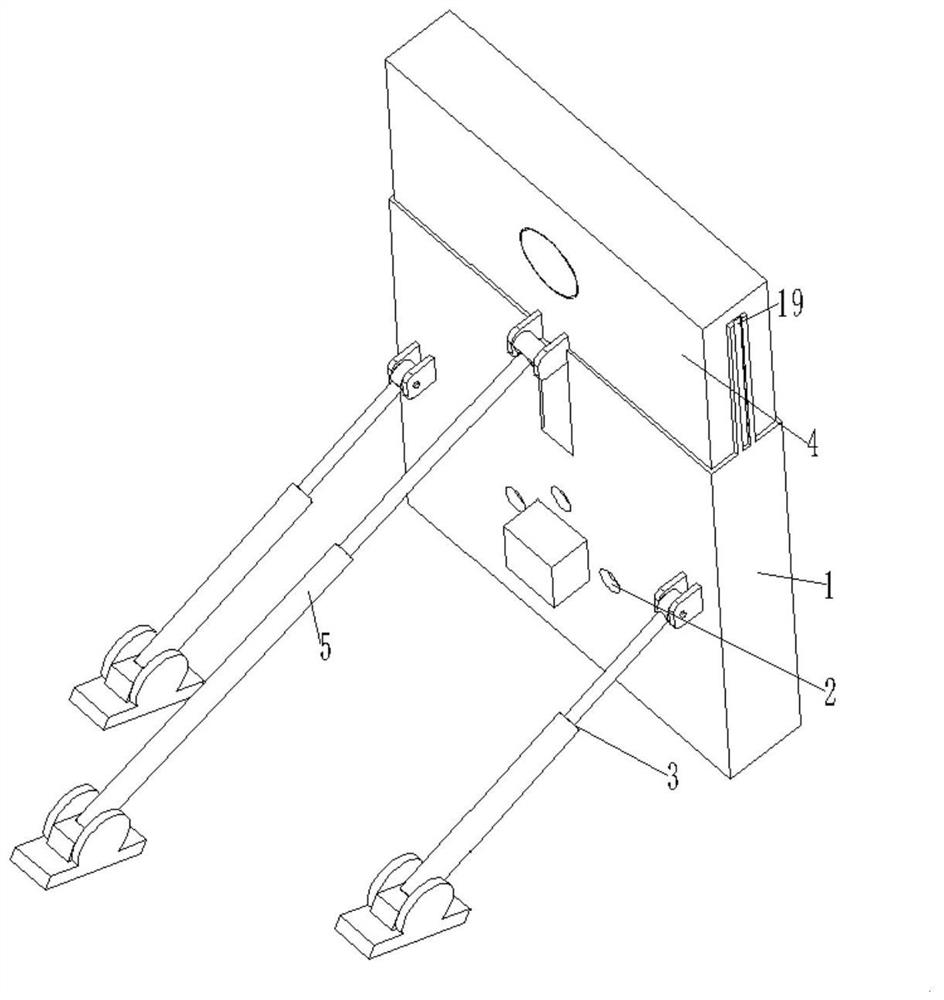

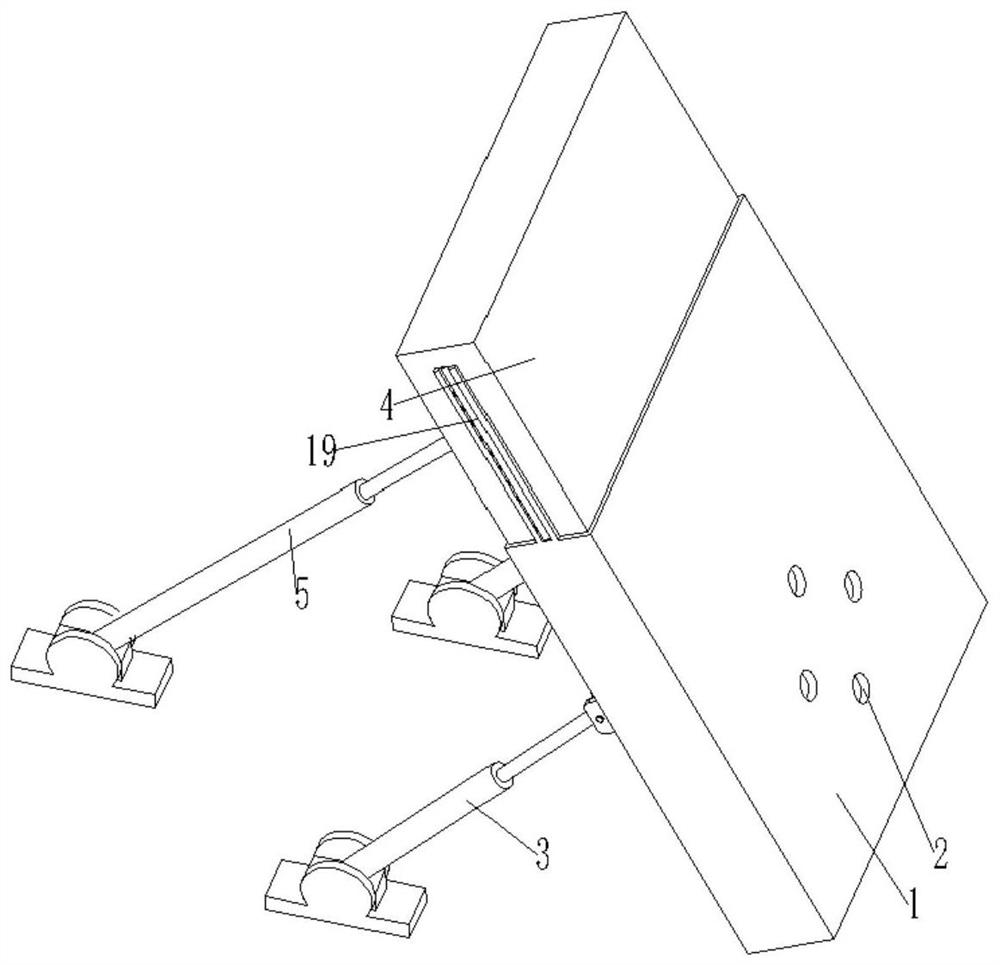

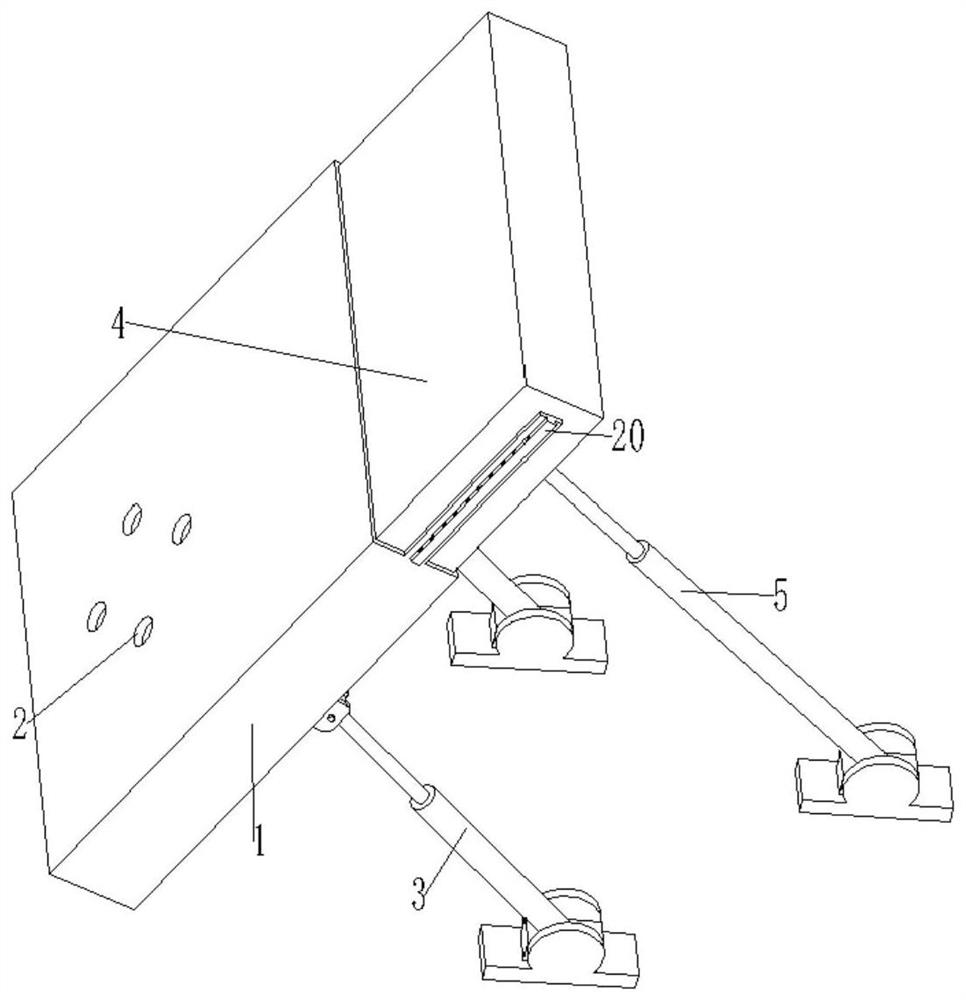

[0030] see figure see Figure 1 to Figure 7 , the present invention provides a technical solution: an automatically controlled flap rubber dam, comprising a flap main body 1, a flow channel 2, an auxiliary baffle 4 and an auxiliary connection and fixing structure 25;

[0031] One side of the flap main body 1 is symmetrically connected with a first hydraulic telescopic rod 3, a flow channel 2 is arranged symmetrically through the flap main body 1, and an auxiliary baffle 4 is movably connected in the flap main body 1, and the auxiliary baffle 4 One side of the connection is provided with a second hydraulic telescopic rod 5;

[0032] There is a first ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com