Open caisson construction method

A construction method and caisson technology, applied to caissons, manufacturing tools, metal processing equipment, etc., can solve problems such as well pipe damage, achieve the effect of reducing vibration and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below with reference to the accompanying drawings.

[0038] The invention discloses a caisson construction method, comprising the following steps:

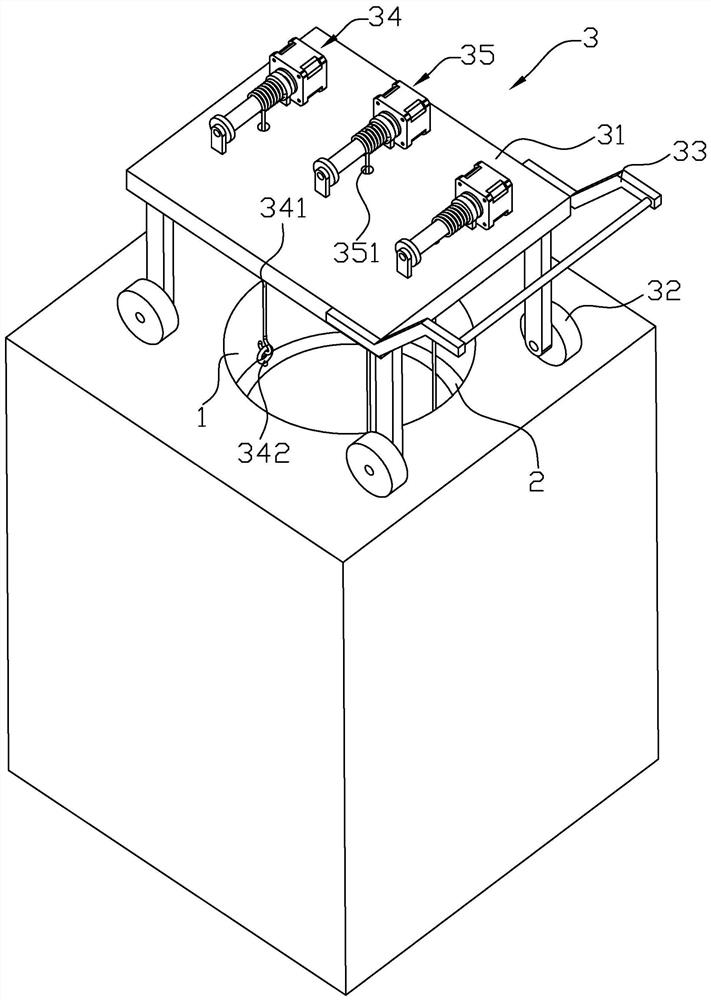

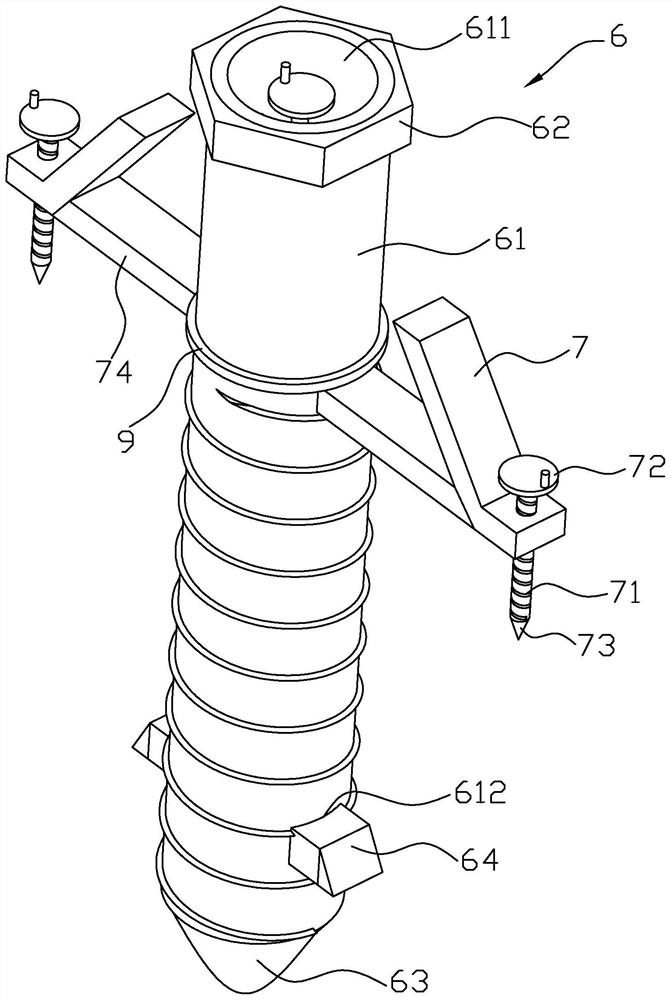

[0039] S1. Lift the well pipe 2 through the lifting device 3: the lifting device 3 includes a moving frame 31, a roller 32 installed at the bottom of the moving frame 31, and a handrail 33 installed at the top of the moving frame 31; The first winch 34, each first winch 34 includes a first steel strand 341, and the end of the first steel strand 341 away from the first winch 34 is fixed with a lifting lug 342; Then, the lifting lugs 342 are threadedly connected with the threaded holes, and then the first hoist 34 is started, and the well pipe 2 can be lifted at this time;

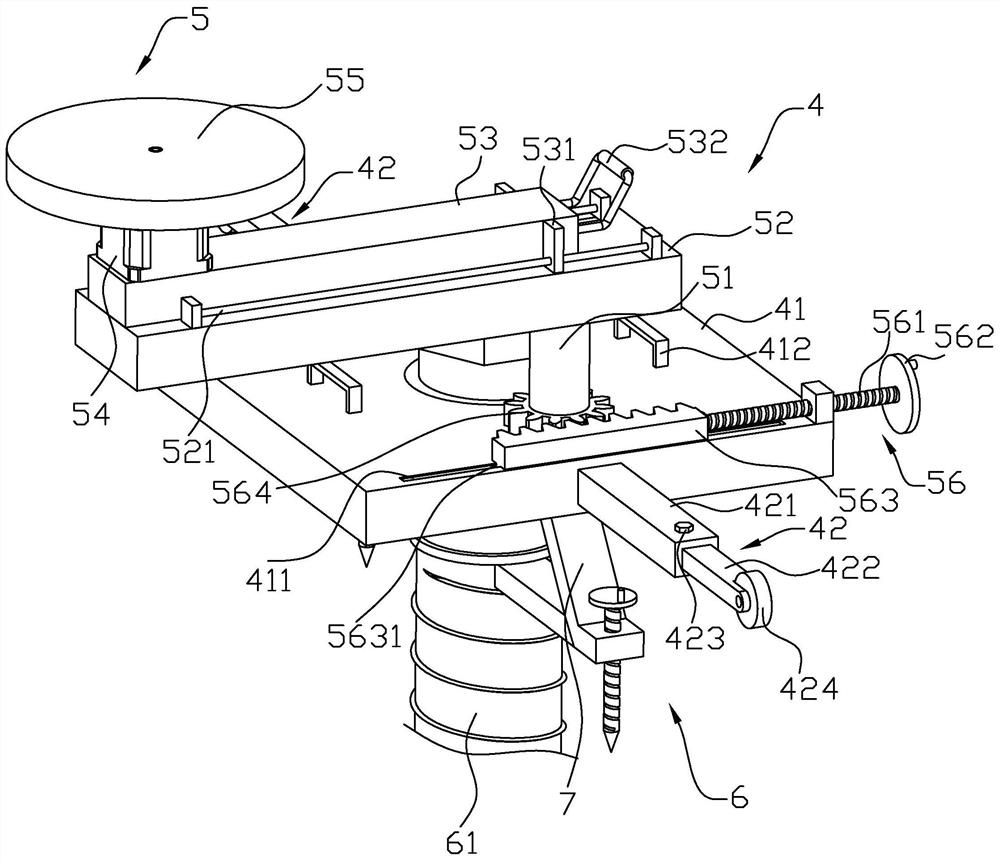

[0040] S2. Grinding the obstacles by the grinding device 4: a second winch 35 is installed on the top of the moving frame 31, the second winch 35 includes a second steel strand 351, and the grindi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com