A trajectory planning method for laser profiling process oriented to the evolution of chemical milling

A technology of trajectory planning and laser engraving, which is applied in the direction of program control, instrument, computer control, etc., can solve the problems of three-dimensional surface and I-shaped structure erosion ratio scaling, and achieve the effect of saving process programming preparation time and requiring less experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make the purpose, technical solution and advantages of the present invention more clear, detailed description will be given below in conjunction with the accompanying drawings.

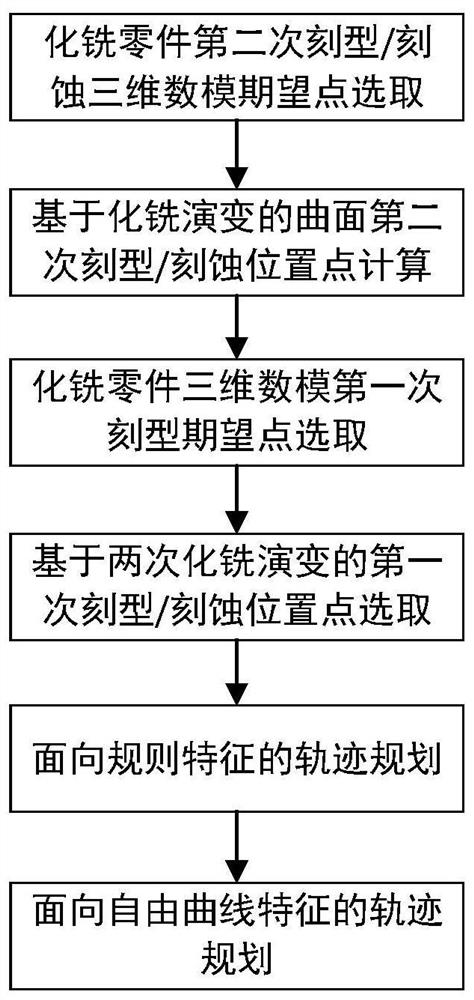

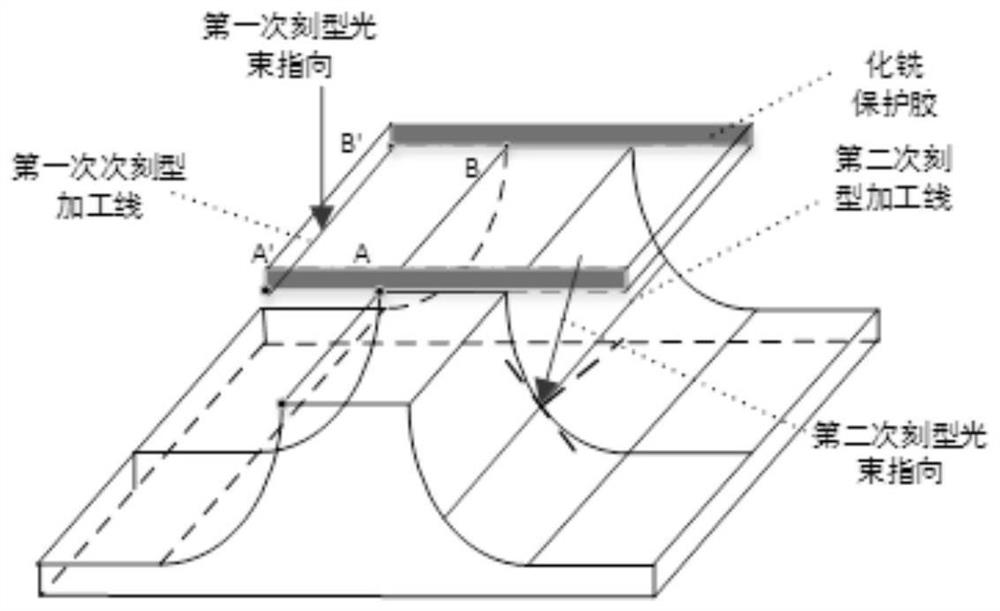

[0043] A trajectory planning method for the laser engraving process oriented to the evolution of chemical milling, such as figure 1 shown, including the following steps:

[0044] STEP1: Selection of expected points based on 3D digital modeling of chemical milling parts;

[0045] Read the 3D digital model information of the chemical milling part, and select the desired point of the 3D digital model:

[0046] The expected point can be selected from any fixed position point on the model; or, the expected point can also be selected to obtain the expected point of laser engraving after the discretization of the three-dimensional digital-analog boundary curve;

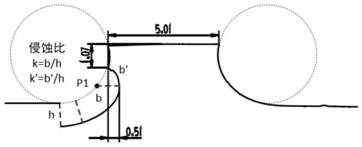

[0047] Read the coordinate information of the desired point; read the boundary curve or surface information where the desired po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com