Preparation device and preparation method of standard mixed gas

A mixed gas and preparation device technology, applied in the direction of mixing methods, mixers, chemical instruments and methods, etc., can solve problems affecting the filling accuracy of standard mixed gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

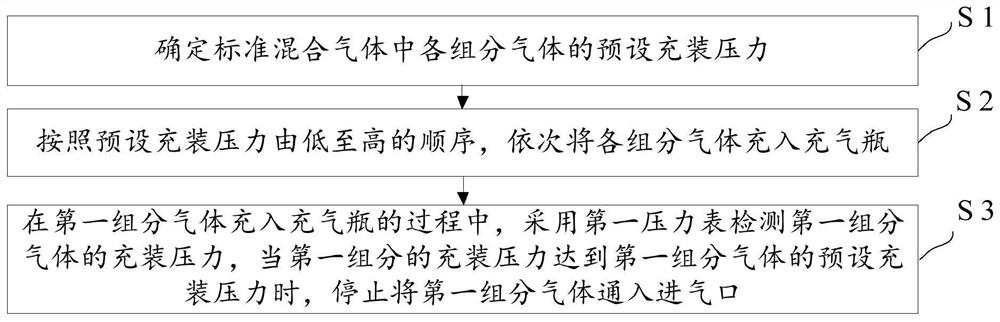

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

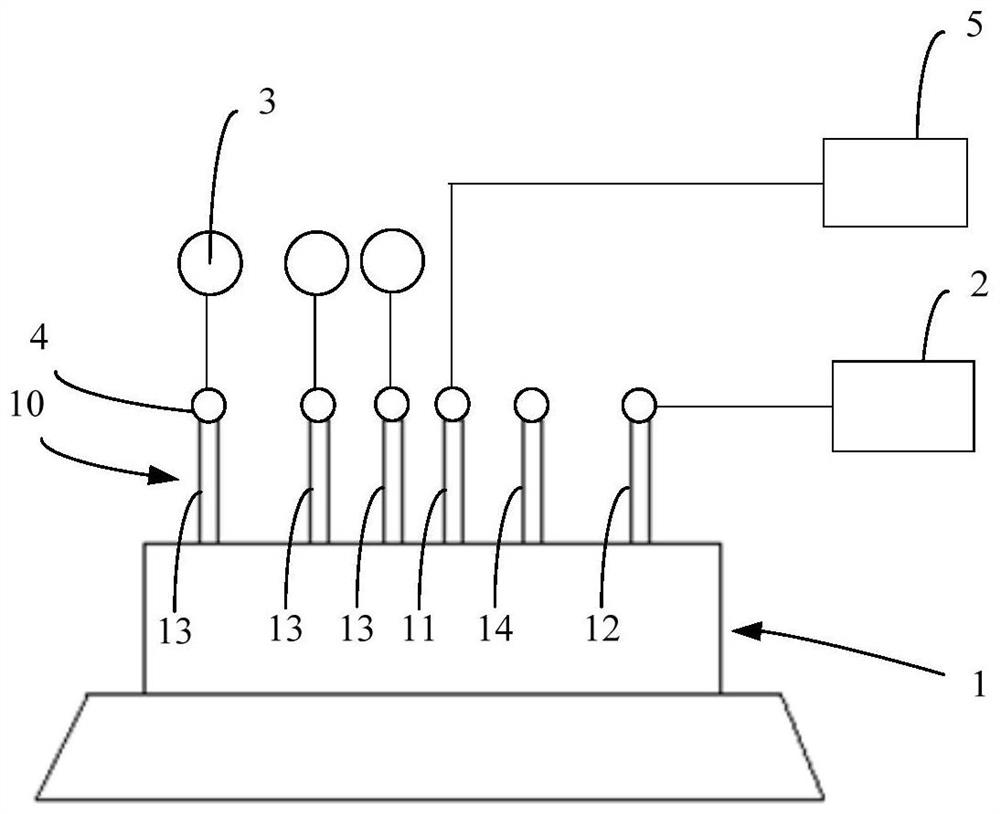

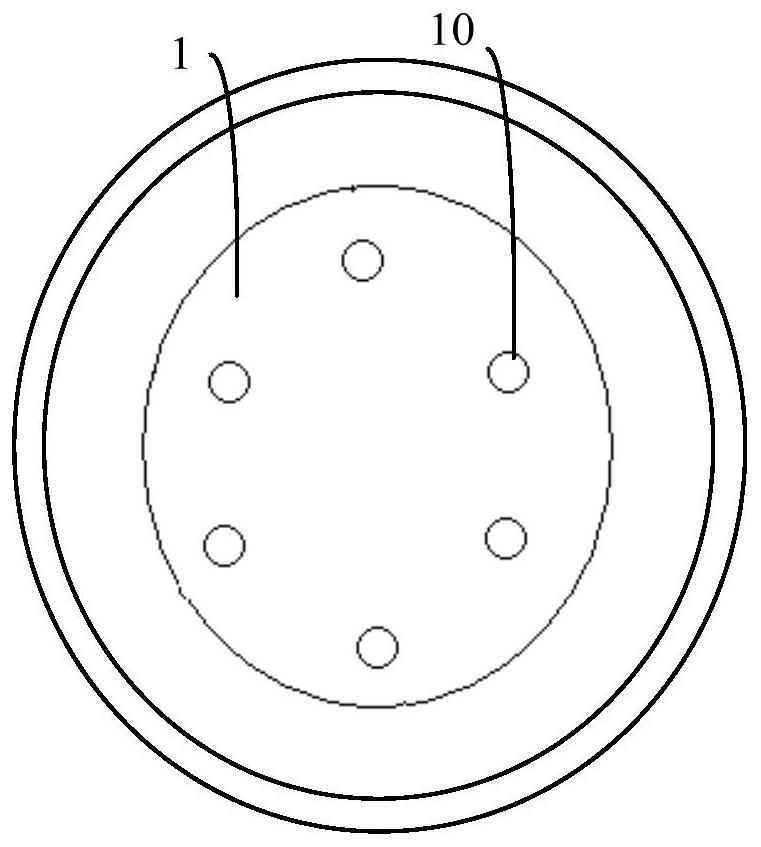

[0026] figure 1 It is a structural schematic diagram of a standard mixed gas preparation device provided by the embodiment of the present invention. like figure 1 As shown, the preparation device includes: an airtight body 1, a gas distribution bottle 2, a pressure gauge 3, and an inflatable bottle 5. The airtight body 1 has a control chamber, and the airtight body 1 is provided with a plurality of communication ports 10 communicating with the control chamber. The airtight body A plurality of communication ports 10 of 1 are connected with valve 4.

[0027] Wherein, there may be multiple inflatable bottles, which are the same as the number of component gases of the standard mixed gas, and one component gas is stored in each inflatable...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com