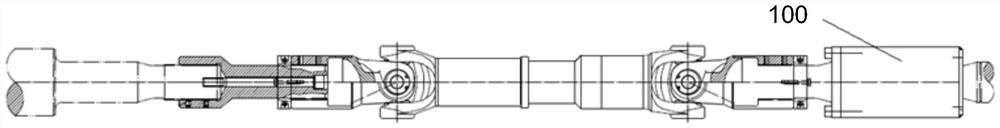

Hydraulic type anti-sliding safe coupling device for hot rolling finishing straightening machine

A hydraulic and fine-leveling technology, which is applied in the field of hydraulic anti-skid safety pick-up devices for hot-rolling fine-leveling machines, can solve the problems of little value and increase the maintenance cost of spare parts, so as to reduce the use and maintenance costs and avoid repairs. The effect of excessive costs and reduced downtime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

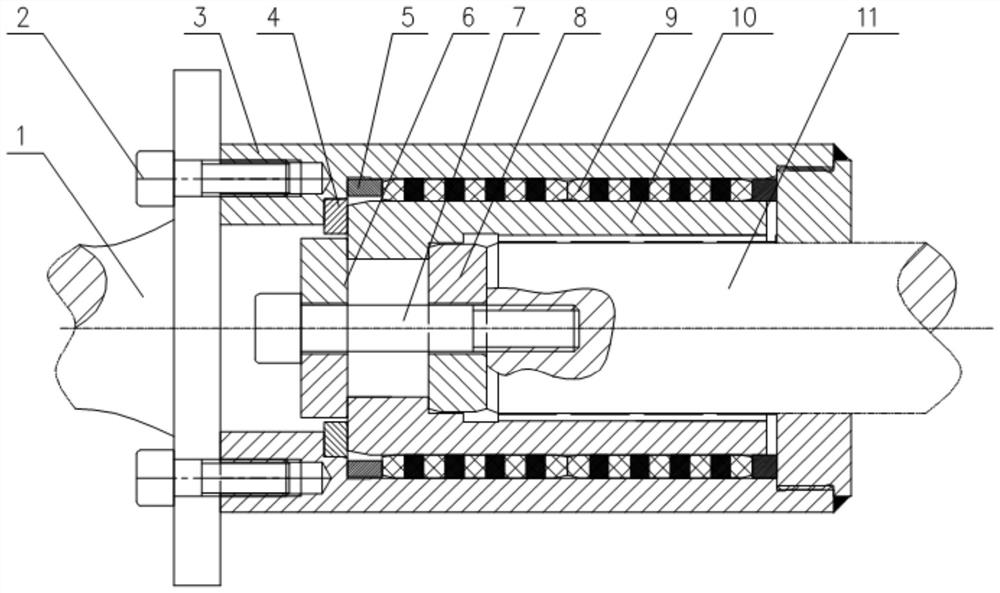

[0031] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0032] Please combine Figure 4 to Figure 7 As shown, a hydraulic anti-slip safety takeover device for a hot-rolled finish leveler provided by the present invention is installed on a transmission shaft 21, and includes an outer ring steel sleeve 22, an inner steel sleeve 23 and a hydraulic mechanism.

[0033] Preferably, the inner steel sleeve 23 is set on the outer circumference of the transmission shaft 21, the outer ring steel sleeve 22 is sleeved on the outer circumference of the inner steel sleeve 23, and the outer ring steel sleeve 22 and the inner steel sleeve 23 are pressed into A certain amount of abrasive material 25 is filled, and the left end of the outer ring steel sleeve 22 is connected to the main shaft 20 by fastening bolts 26, and the right end of the main shaft 20 is connected to the left end of the transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com