A kind of gh4163 annular forging die forging method

A technology of GH4163, ring forging, applied in the direction of manufacturing tools, forging/pressing/hammer devices, forging/pressing/hammering machinery, etc., can solve the problems of coarse grains, easy cracks, uneven structure and performance, etc. Achieve uniform deformation of forgings, improve surface quality, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

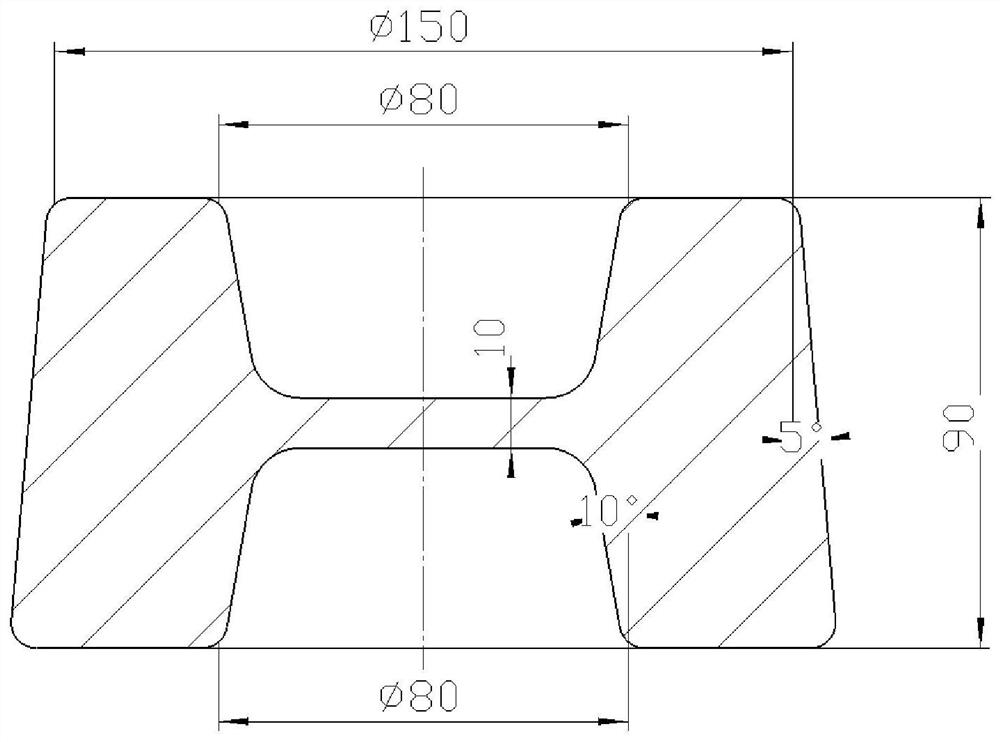

[0030] Step 1: Forging drawing design

[0031] The part is a ring, with an extra allowance of 5mm for the outer diameter and 5mm for the inner diameter. The forging slope of the outer wall is designed to be 5° according to the height of the ring, and the slope of the outer wall is from one end to the other end of the height of the ring; The height dimension of the ring is designed to be 10°, the slope of the inner wall is from both ends of the height of the ring to the middle position, and the thickness of the middle skin is 10mm; 5mm is added to one side in the height direction. figure 1 It is the forging drawing obtained after adding allowance to the part drawing.

[0032] Step 2: tire mold design

[0033] The tire mold mold includes a jacket, an upper punch and a lower punch. Jacket: The height of the jacket is the same as that of the forging, the inner wall of the jacket is the same size as the outer wall of the forging, and the slope is the same; the diameter of the tai...

Embodiment 2

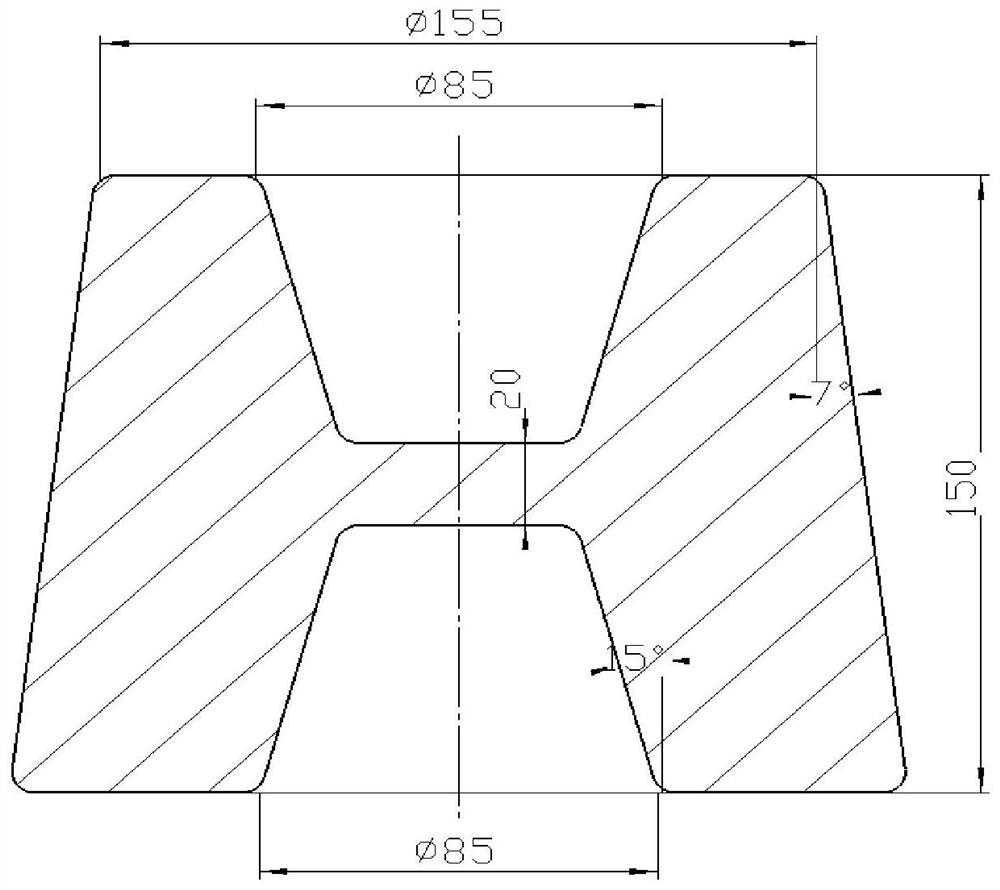

[0048] Step 1: Forging drawing design

[0049] The part is a ring, with an extra allowance of 5mm for the outer diameter and 5mm for the inner diameter. The forging slope of the outer wall is designed to be 7° according to the height of the ring. The slope of the outer wall is from one end to the other end of the height of the ring; The height dimension of the piece is designed to be 15°, the slope of the inner wall is from both ends of the height of the ring piece to the middle position, and the thickness of the middle skin is 20mm; 5mm is added to one side in the height direction. figure 2 It is the forging drawing obtained after adding allowance to the part drawing.

[0050] Step 2: tire mold design

[0051] The tire mold mold includes a jacket, an upper punch and a lower punch. Jacket: The height of the jacket is the same as that of the forging, the inner wall of the jacket is the same size as the outer wall of the forging, and the slope is the same; the diameter of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com