Storage and conveying device for sludge recycling reinforcing agent

A technology of conveying device and reinforcing agent, which is applied in the direction of conveying bulk materials, conveyors, transportation and packaging, etc. It can solve the problems that the reinforcing agent cannot be guaranteed to be in powder form, and achieve the effect of preventing moisture, solidification and agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

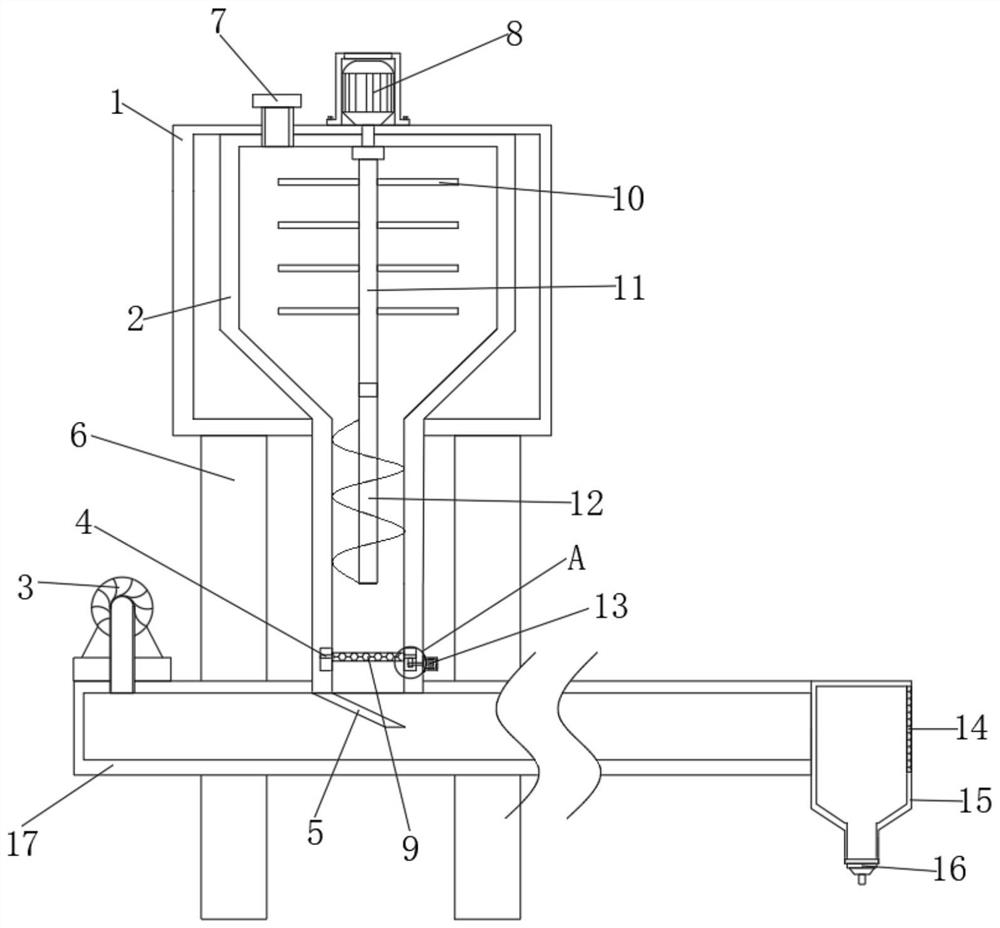

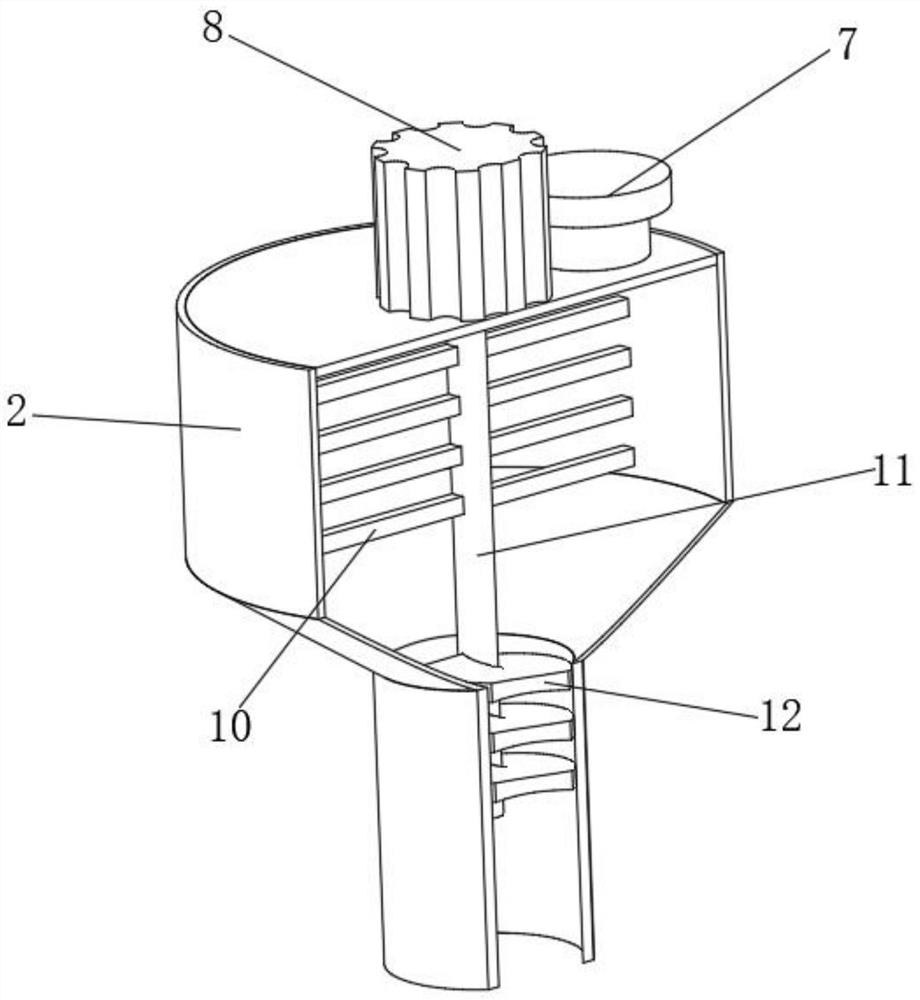

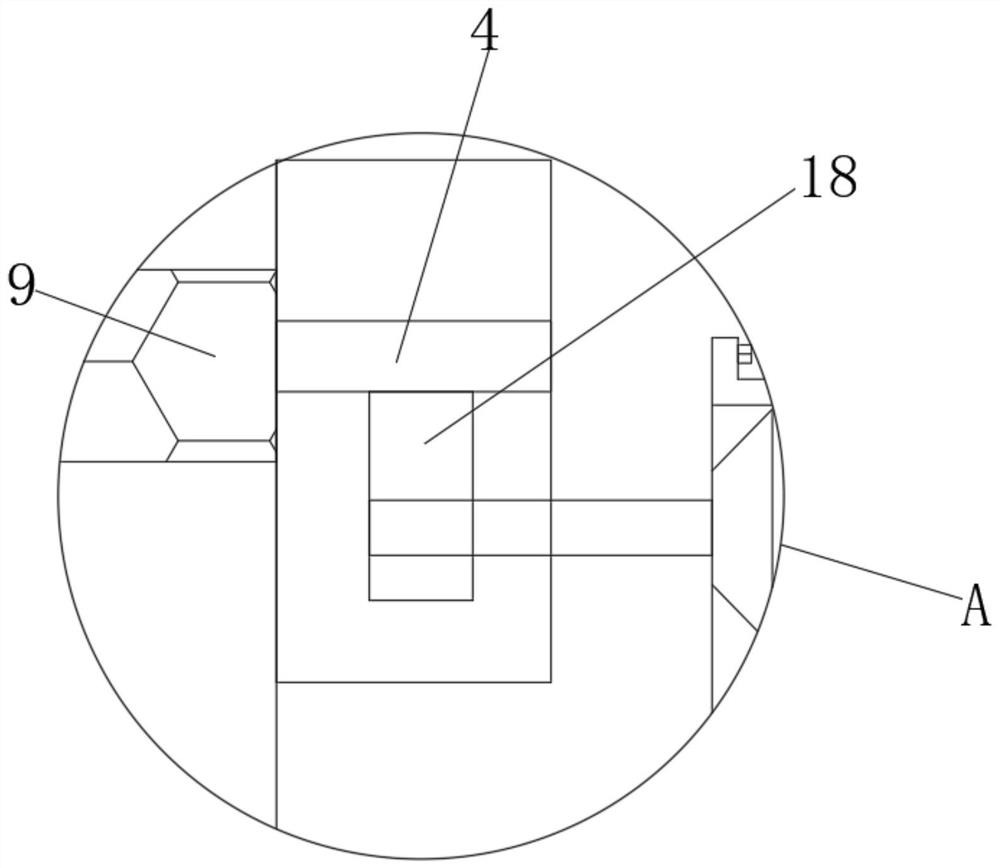

[0023] refer to Figure 1-3 , a storage and delivery device for a sludge reuse enhancer, including a body 1, a storage box 2 is provided on the top inner wall of the body 1, and a first rotating motor 8 is provided on the top of the body 1, and the body 1 and The top outer wall of the material storage box 2 has the same feed port 7, and the first rotating motor 8 extends to the output shaft one end in the material storage box 2 and is connected with the rotating shaft 11 by a shaft coupling, and the circumference outer wall of the rotating shaft 11 is provided with There are a plurality of stirring paddles 10, one end of the rotating shaft 11 is connected with an auger 12 through a coupling, both sides of the bottom of the material storage box 2 are provided with limiting grooves, and the inner wall of the limiting groove is slidably connected with a slider 4, the sliding The opposite side outer wall of block 4 is provided with same filter screen plate 9, and the side outer wa...

Embodiment 2

[0030] refer to Figure 4 , a storage and conveying device for sludge reuse enhancer, compared with Embodiment 1, the outer wall of one side of the fuselage 1 is provided with a second fan 23, and the air inlet end of the second fan 23 is provided with a second air inlet The exhaust end of the second blower fan 23 is provided with a second exhaust pipe extending between the fuselage 1 and the storage box 2, and the outer wall of one side of the fuselage 1 is provided with a plurality of second ventilation holes 19. One end of the exhaust pipe is provided with a heating box 21 , and a plurality of heating wires 20 are provided on the inner walls of both sides of the heating box 21 , and an air outlet 22 is opened on the inner wall of the bottom of the heating box 21 .

[0031] During use, when unloading, the air is blown into the heating box 21 by the second fan 23, the air is heated by the heating wire 20, and then the warm air is discharged between the material storage box 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com