Sling torsion proof device, lifting winding system, and port crane

A spreader and anti-twist technology, which is used in hoisting devices, portable lifting devices, transportation and packaging, etc., can solve the problems of inefficiency of operator experience, dependence on efficiency, over-dependence, etc., so as to avoid increased twisting of the spreader, Improve loading and unloading efficiency and eliminate the effect of inertial twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

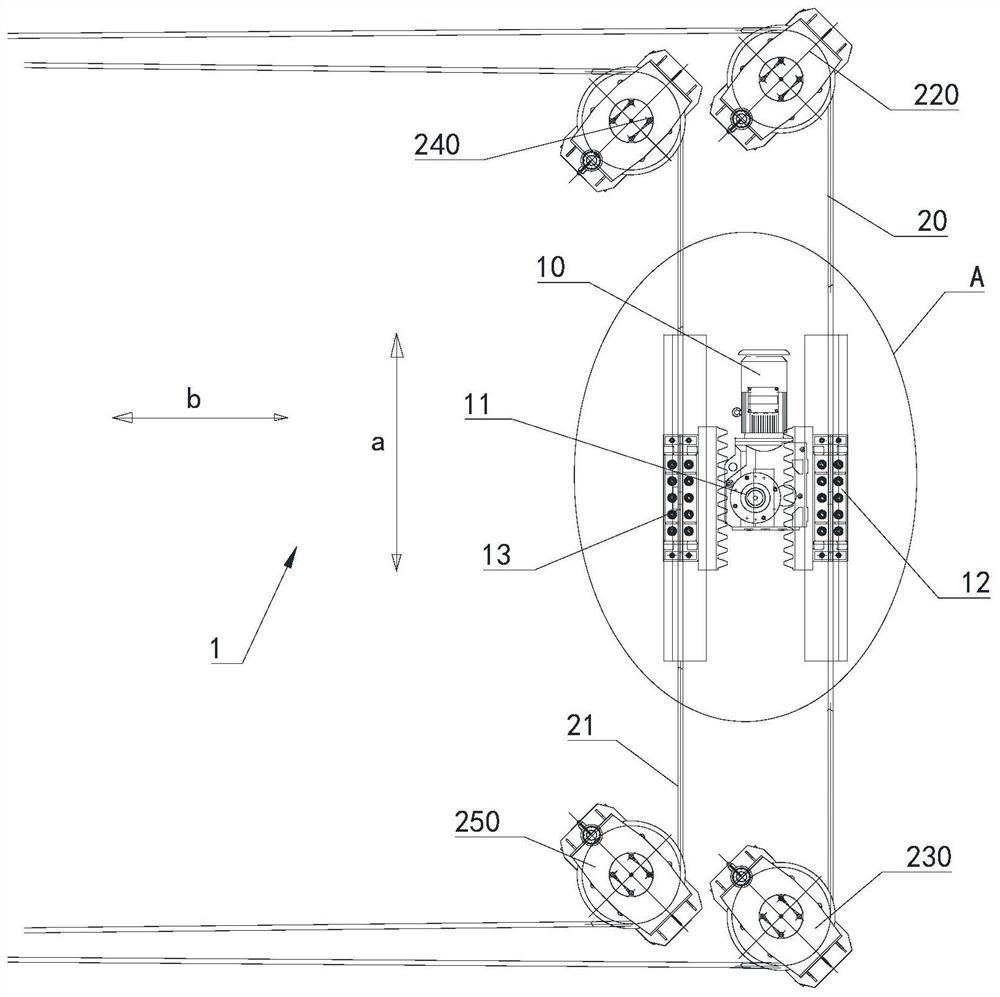

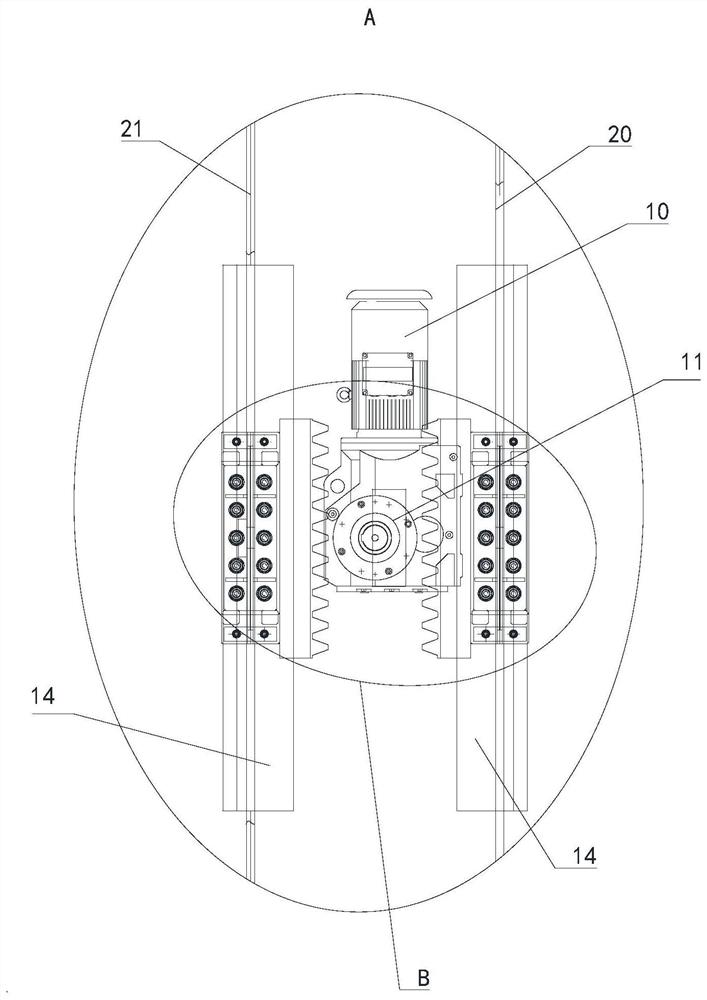

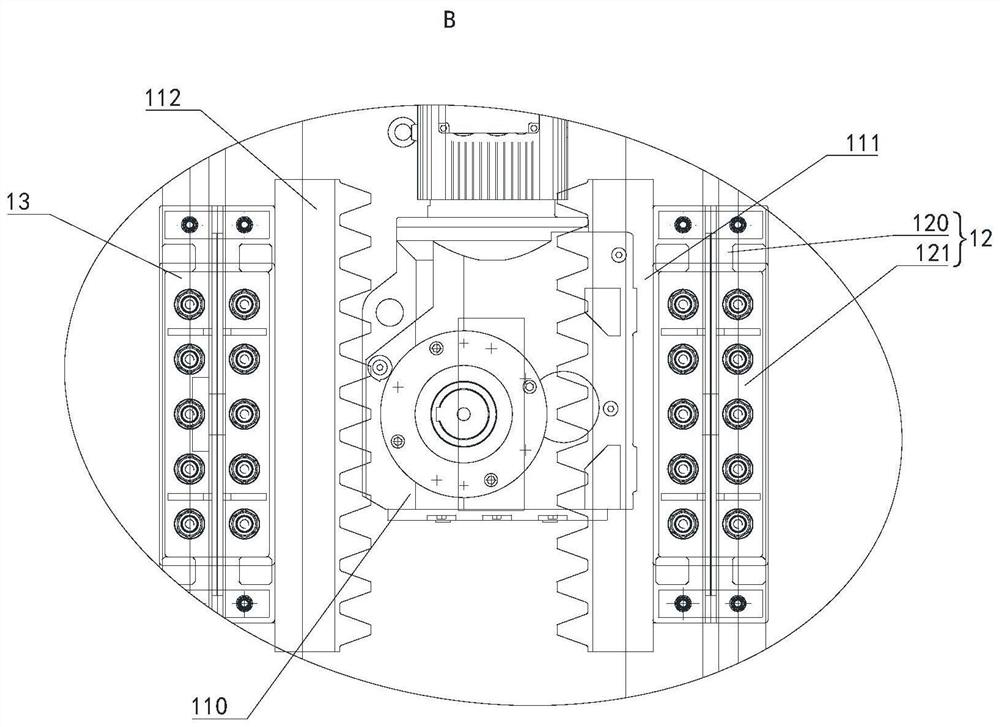

[0043] see Figure 1 to Figure 3 As shown, the present embodiment provides an anti-twist device for a spreader; figure 1 The structural diagram of the anti-torsion device of the spreader provided in this embodiment, in the figure, a shows the first direction, and b shows the second direction; figure 2 for figure 1 Partial enlarged view at A; image 3 for figure 2 Partial enlarged view at B.

[0044] The anti-twist device of the spreader provided in this embodiment is used for lifting the winding system.

[0045] see Figure 1 to Figure 3 and combine Figure 4 As shown, the anti-torsion device 1 for the spreader provided in this embodiment includes a driving assembly, a transmission assembly 11 and a fixing assembly.

[0046] The fixing assembly is arranged on the transmission assembly 11 and is used for fixing the steel wire rope assembly connected to the sling 26; the driving assembly can drive the transmission assembly 11 to reciprocate and translate along the first d...

Embodiment 2

[0068] Embodiment 2 provides a lifting winding system, which includes the anti-twist device of the spreader in Embodiment 1. The technical features of the anti-twist device of the spreader disclosed in Embodiment 1 are also applicable to this embodiment. The technical characteristics of a disclosed anti-twist device for a spreader will not be described repeatedly.

[0069] Figure 4 The structural schematic diagram of the lifting winding system provided in this embodiment, in order to express the structure more clearly, adopts the axonometric drawing.

[0070] combine Figure 1 to Figure 3 and see Figure 4 As shown, the lifting winding system 2 provided in this embodiment includes the anti-twist device 1 for the spreader provided in the first embodiment.

[0071] In the optional solution of this embodiment, the lifting winding system 2 includes a spreader 26, a first steel wire rope 20, a second steel rope 21, four pulley blocks and a spreader anti-twist device 1; the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com