Collaborative optimization design method of molten iron kr stirring desulfurization device and stirring process

A stirring process and collaborative optimization technology, applied in multi-objective optimization, instrumentation, geometric CAD, etc., can solve problems such as restrictive technology and complex influence rules, improve dynamic conditions, improve technical and economic indicators of molten iron KR stirring desulfurization, shorten The effect of desulfurization stirring time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

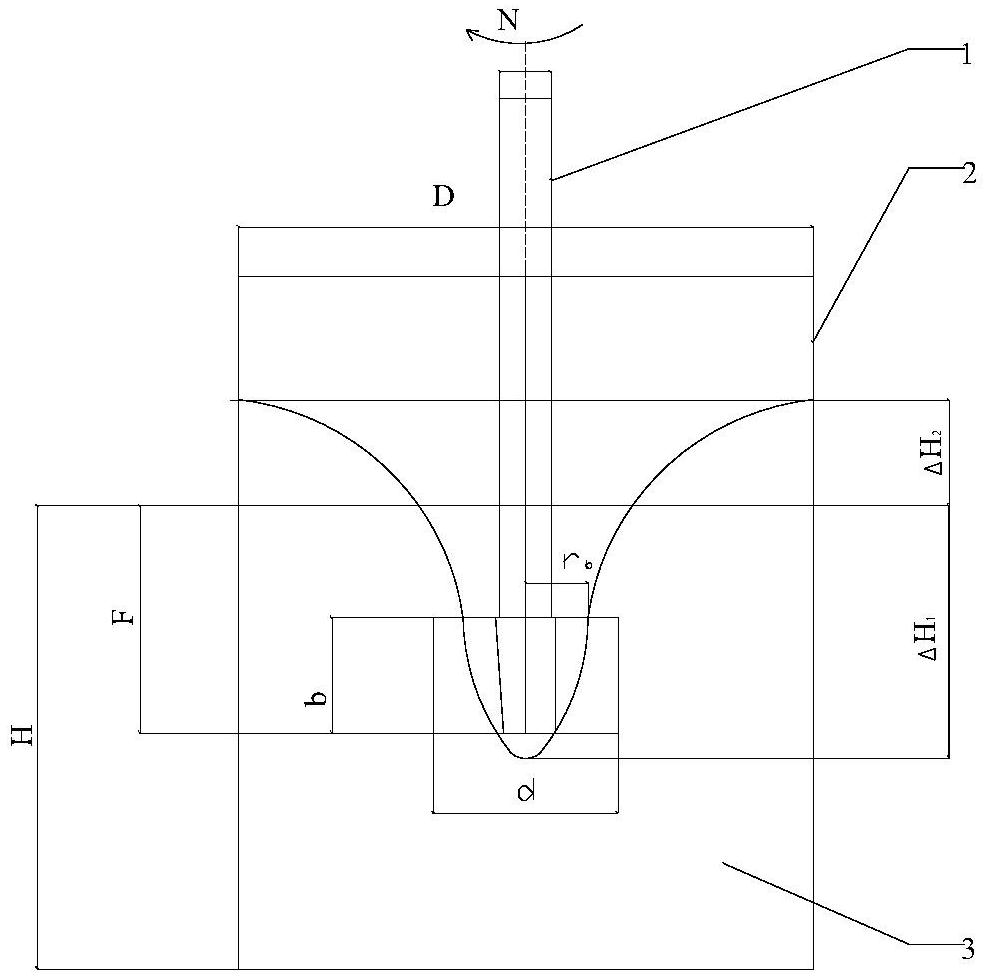

[0134] Such as figure 1 The shown method for the collaborative optimization design of the hot metal KR stirring desulfurization device and stirring process for a 300-ton hot metal tank in a steel plant includes the following steps:

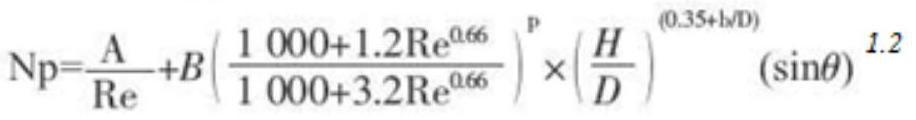

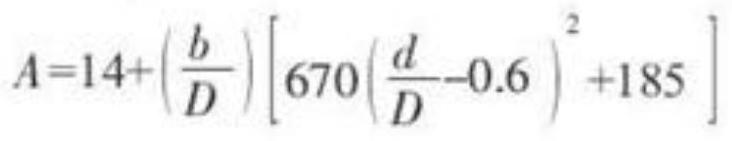

[0135] 1) A steel mill uses the original injection desulfurization molten iron tank to carry out KR desulfurization transformation. The shape of the molten iron tank is a straight cylindrical structure. The rated loading capacity of molten iron is W = 295t. The diameter of the straight section of the molten iron tank is the average diameter of the molten iron tank D = 3.853m. The total height of the inner void of the molten iron tank is 5.500m, the height of the inner void at the bottom of the rounded platform tank is 0.940m, the inner diameter of the bottom is 1.600m, and the density of molten iron is ρ=6.500g / cm 3 , it can be calculated that under the condition of the rated loading capacity of molten iron, the height H of the molten iron level i...

Embodiment 2

[0153] Such as figure 1 The shown method for the collaborative optimization design of the molten iron KR stirring desulfurization device and the stirring process of an 80-ton molten iron tank in a steel plant includes the following steps:

[0154] 1) A steel mill newly built a hot metal KR stirring desulfurization station with an 80-ton hot metal tank. The shape of the hot metal tank is a straight cylindrical structure with a spherical crown bottom. The rated loading capacity of the hot metal is W=80t. Diameter D=2.9m, take molten iron density ρ=6.500g / cm 3 , it can be calculated that under the condition of rated loading capacity, the height H of the molten iron level is 2.39m, and the inner empty height of the molten iron tank is 3.263m. The free space height of the hot metal tank h=0.873m>0.30×2.9=0.870m.

[0155] 2) According to the design experience of the molten iron KR stirring device, set the structural parameters of the stirring device and the optimal design calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com