Seed crystal laying method for casting monocrystalline silicon and application

A laying method and monocrystalline silicon technology, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of low utilization rate of monocrystalline silicon round rods for seed crystals and high cost of single crystal seed crystals , to achieve the effect of simple and easy operation of the laying method, less dislocations and suppression of dislocations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

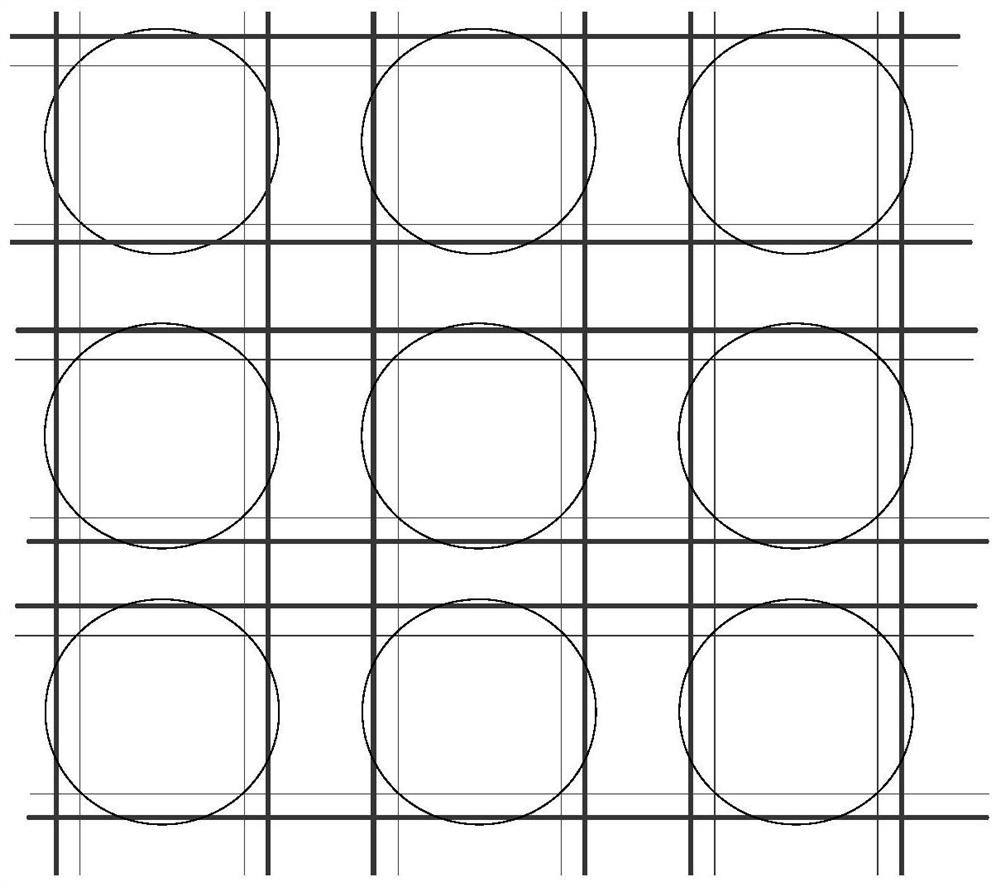

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

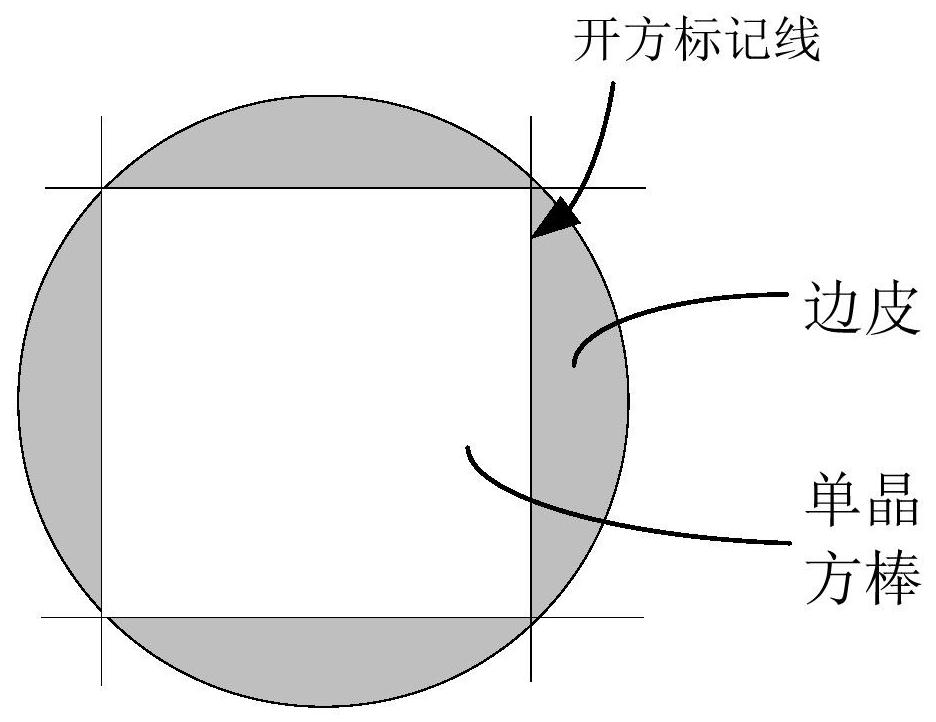

[0029] In order to better understand the single crystal seed crystal laying method for single crystal silicon casting provided by the present invention, the edge seed crystal used therein will be introduced first.

[0030] The edge seed crystal used in the present invention is obtained by cutting the edge of the single crystal silicon round rod after square cutting. Specifically, it can be prepared by the following exemplary methods:

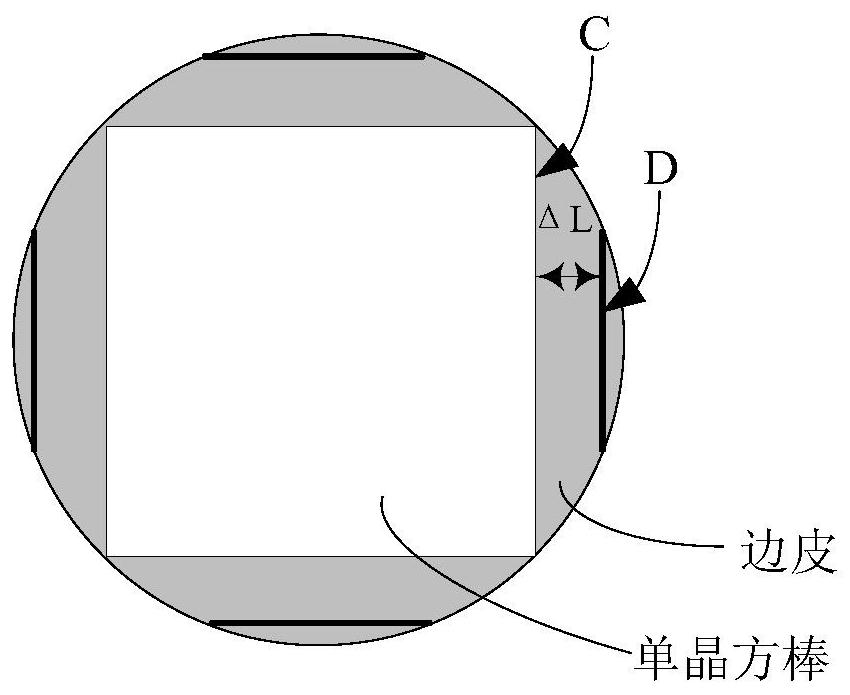

[0031] S101, provide a single crystal silicon round rod with a crystal orientation of the growth plane (100), determine four square root marking lines (can be denoted as C) on the cross section of the single crystal silicon round rod, and mark the four square root The line is translated by ΔL along the direction away from the center of the cros...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com