Auxiliary piling system and piling machine with same

A technology for pile drivers and control units, which is applied in the field of pile drivers, can solve the problems of low efficiency and high skill requirements for operators, and achieve the effect of reducing use costs, reducing skill requirements, and improving piling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

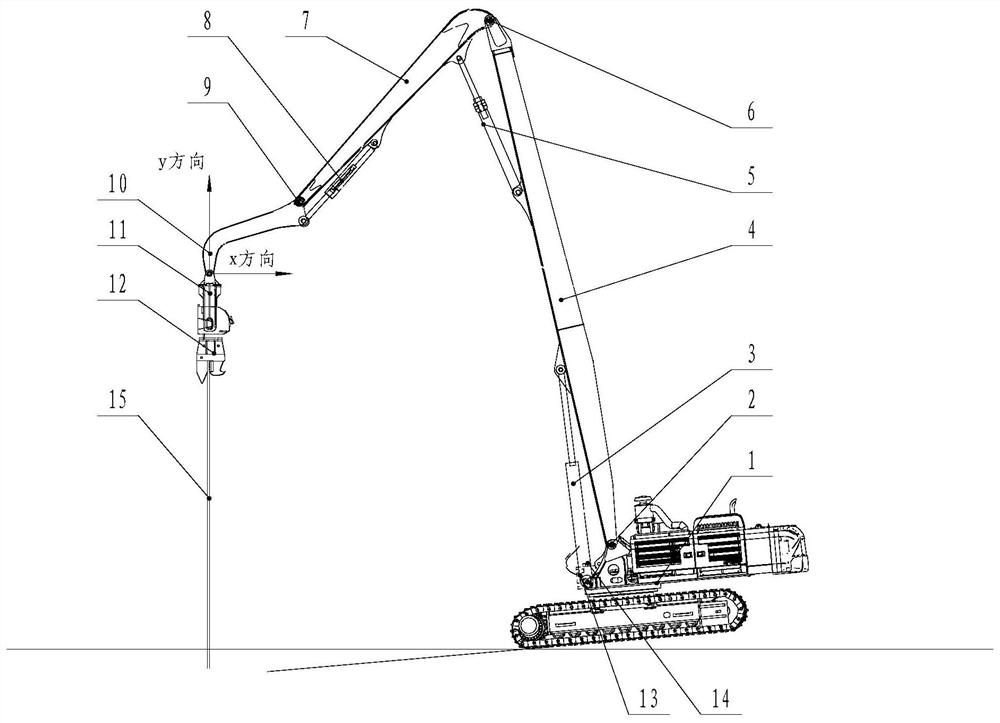

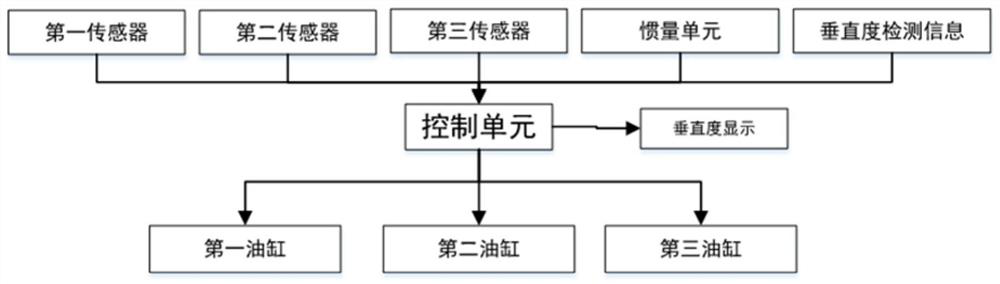

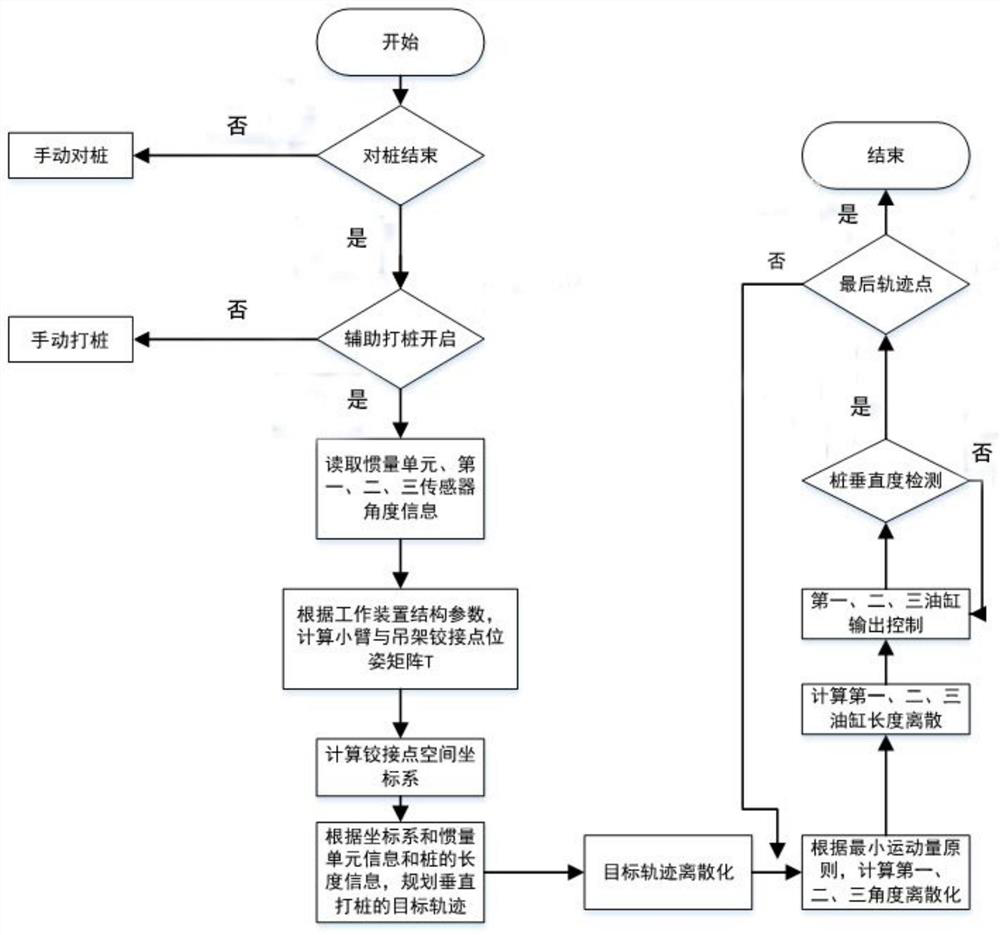

[0024] Such as figure 1 As shown, an auxiliary piling system includes a sensor assembly and a control unit. The sensor assembly includes an angle sensor unit, a perpendicularity detection unit 13 and an inertia unit 14. The angle sensor unit is installed on the work device for real-time monitoring of the angle information of the work device and fed back to the control unit to form a closed-loop control; the verticality detection unit 13 , used to detect the verticality information of the pile and transmit it to the control unit; the inertia unit 14 is used to detect the space and angle information of the construction surface where the pile driver is located; the control unit is connected with the sensor component, and obtains the angle of the sensor component Calculate the spatial position coordinates of hammer head 12 and pile 15 based on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com