Hob trailing head trailing suction hopper dredger driven by outer-rotor motor

A technology of trailing suction dredger and external rotor motor, which is applied to mechanically driven excavators/dredgers, earth movers/shovels, construction, etc., can solve the problem of limited dredging efficiency, reduced excavation efficiency, and frequent maintenance failures. Increase and other problems to achieve the effect of improving the strength range of the excavated soil, the high speed and speed regulation range, and reducing the axial restraint accessories

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing and embodiment, but present embodiment is not intended to limit the present invention, and all adopt similar structures of the present invention and similar changes thereof, all should be included in the scope of protection of the present invention.

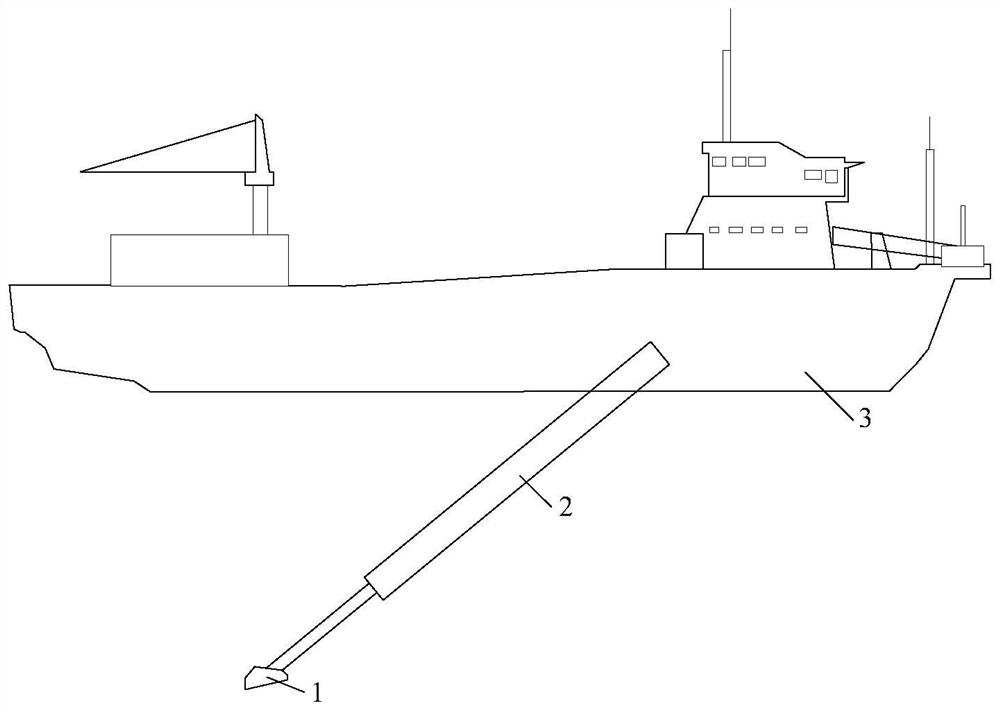

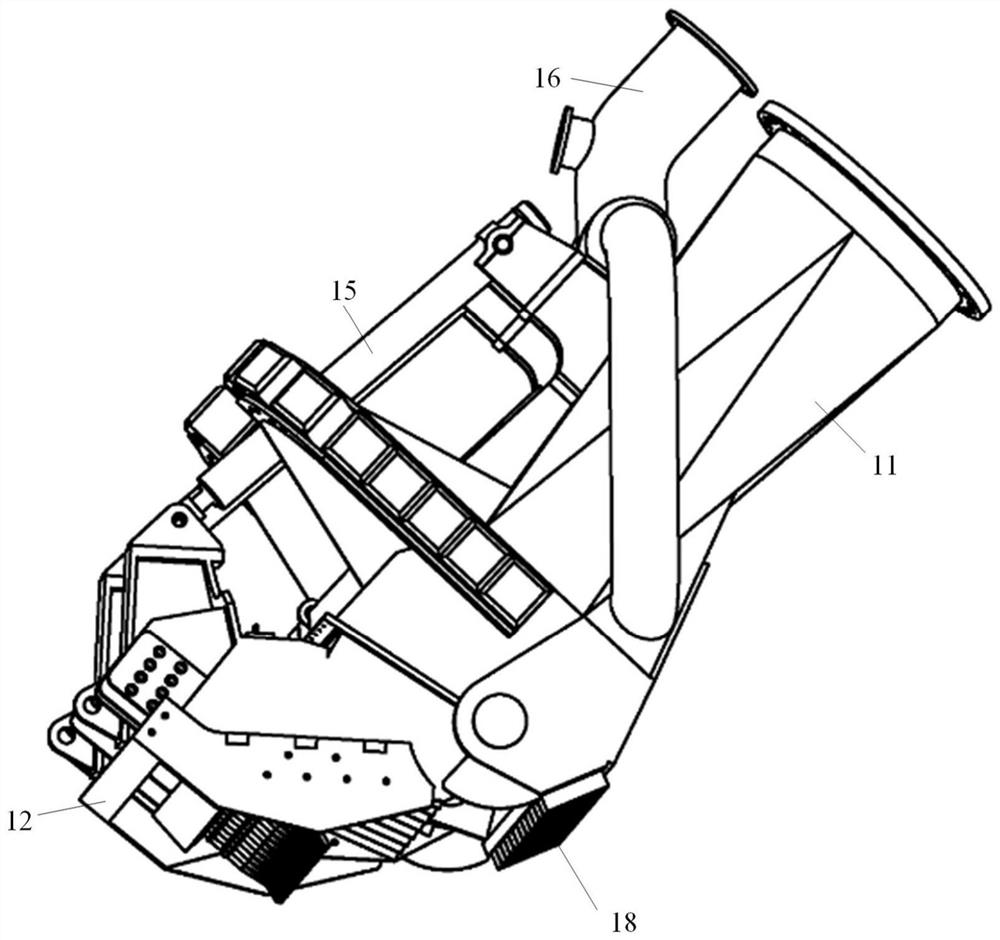

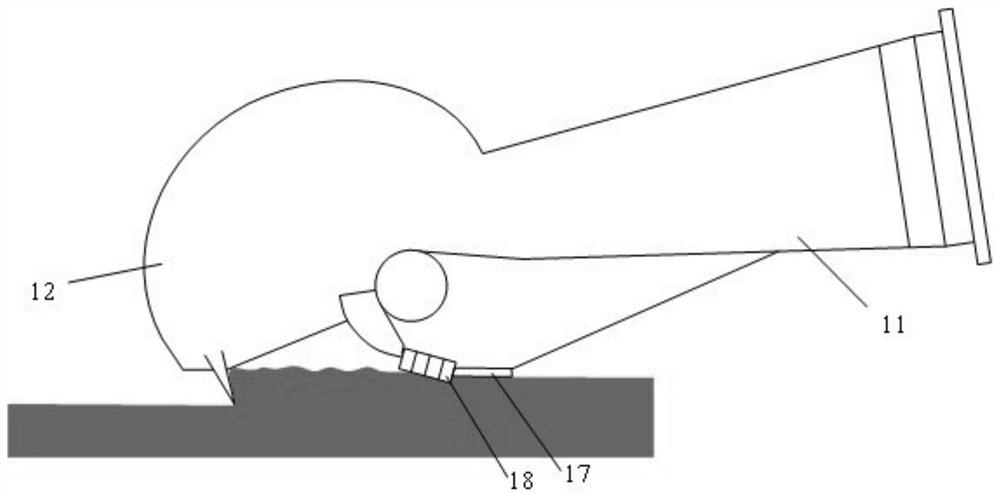

[0041] A trailing suction dredger with a hob rake head driven by an external rotor motor includes a rake head 1 connected to a hull 3 through a rake arm. Such as Figure 5-7 The hob rake head shown includes: rake head fixed body 11, rake head movable cover 12, drum 13 with rake teeth, outer rotor motor 14, hydraulic device 15, high-pressure flushing elbow 16, rake head movable cover 12 and rake head fixed body 11, the cylinder 13 that rake teeth are housed, hydraulic unit 15 are all movably connected. The rake head fixed body 11 is movably connected with the rake head movable cover 12 through pin holes; the roller 13 equipped wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com