Prefabricated anti-water-seepage dismounting-free shear wall form board

A prefabricated assembly and anti-seepage technology, which is applied in the field preparation of formwork/formwork/work frame connectors, walls and building components, and can solve the problem that the shear wall stiffness is greatly weakened and the quality of components is greatly affected. , the problem of high cost of template engineering, to save decoration materials, facilitate transportation and on-site storage, improve disassembly and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

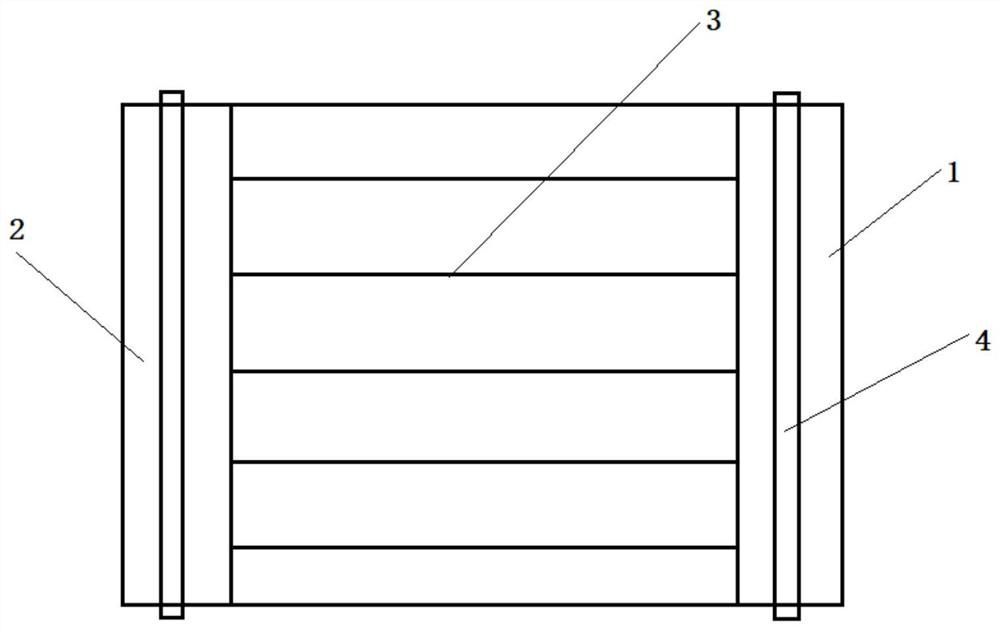

[0032] see Figure 1-2 , a prefabricated anti-seepage formwork for a shear wall without disassembly, including an inner formwork 1, an outer formwork 2 and an inner and outer formwork connector 3, and the inner formwork 1, outer formwork 2 and inner and outer formwork connectors 3 are rigidly connected; The edges of the inner formwork 1 and the outer formwork 2 are provided with a mortise and tenon structure, and the adjacent inner formwork 1 and outer formwork 2 are respectively connected and assembled through the mortise and tenon structure; the inner side of the mortise and tenon structure is provided with a sealing strip 4 , when the formwork is assembled, the corresponding mortise and tenon structures are butted, and the sealing strip 4 effectively prevents the leakage of moisture in the concrete;

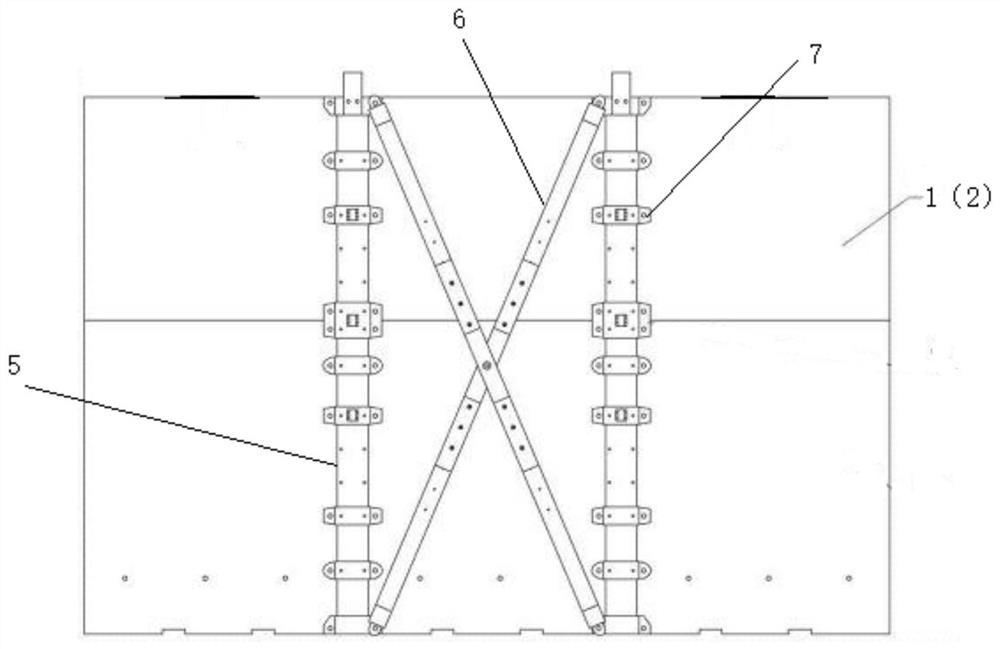

[0033] The outer side of the inner formwork 1 and the outer formwork 2 is provided with a supporting structure, including a seam-riding reinforcement plate 5 located at the jo...

Embodiment 2

[0047] see Figure 1-2 , a prefabricated anti-seepage formwork for a shear wall without disassembly, including an inner formwork 1, an outer formwork 2 and an inner and outer formwork connector 3, and the inner formwork 1, outer formwork 2 and inner and outer formwork connectors 3 are rigidly connected; The edges of the inner formwork 1 and the outer formwork 2 are provided with a mortise and tenon structure, and the adjacent inner formwork 1 and outer formwork 2 are respectively connected and assembled through the mortise and tenon structure; the inner side of the mortise and tenon structure is provided with a sealing strip 4 , when the formwork is assembled, the corresponding mortise and tenon structures are butted, and the sealing strip 4 effectively prevents the leakage of moisture in the concrete;

[0048] The outer side of the inner formwork 1 and the outer formwork 2 is provided with a supporting structure, including a seam-riding reinforcement plate 5 located at the jo...

Embodiment 3

[0068] see Figure 1-2 , a prefabricated anti-seepage formwork for a shear wall without disassembly, including an inner formwork 1, an outer formwork 2 and an inner and outer formwork connector 3, and the inner formwork 1, outer formwork 2 and inner and outer formwork connectors 3 are rigidly connected; The edges of the inner formwork 1 and the outer formwork 2 are provided with a mortise and tenon structure, and the adjacent inner formwork 1 and outer formwork 2 are respectively connected and assembled through the mortise and tenon structure; the inner side of the mortise and tenon structure is provided with a sealing strip 4 , when the formwork is assembled, the corresponding mortise and tenon structures are butted, and the sealing strip 4 effectively prevents the leakage of moisture in the concrete;

[0069] The outer side of the inner formwork 1 and the outer formwork 2 is provided with a supporting structure, including a seam-riding reinforcement plate 5 located at the jo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com