A Safe and Efficient Shallow Hole Room and Pillar Mining Method

A mining method and high-efficiency technology, which is applied in ground mining, mining equipment, mining equipment, etc., can solve problems that affect the safety of the mining process and mining efficiency, large joints and fissures in rock formations, cracking of the roof side of the stope, etc., so as to avoid blasting Disturbance, damage is small, and the effect of reducing the number of blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

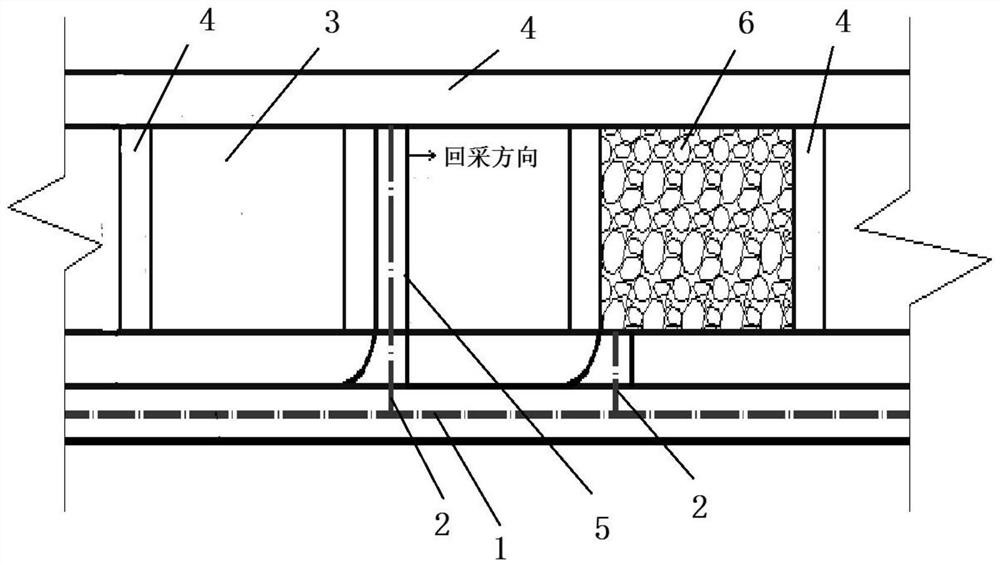

[0036] Such as figure 1 , this embodiment implements mining for the stable ore rock, and the gently inclined lower ore body with a thickness of less than 8 ~ 10m, including the following steps:

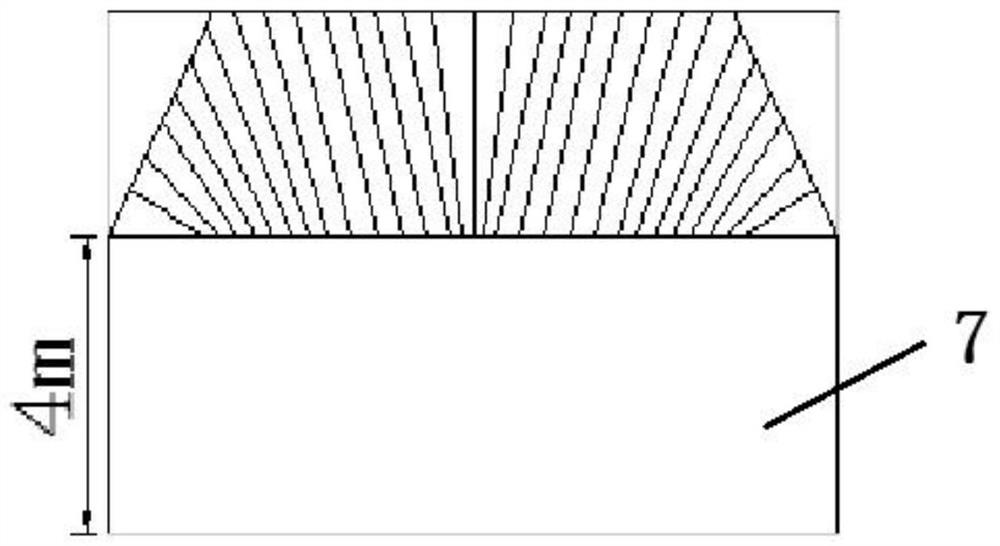

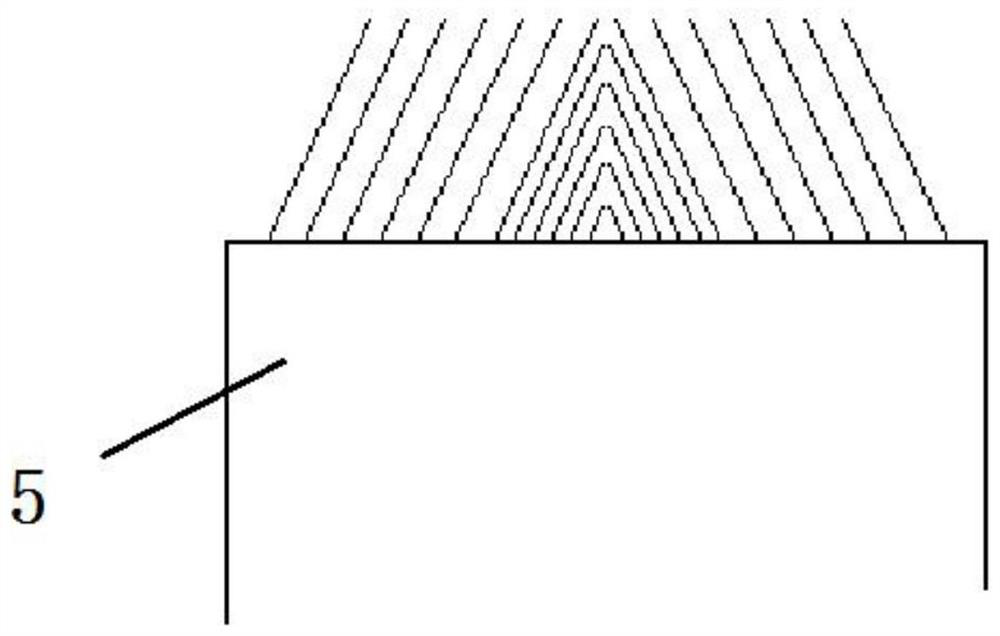

[0037] First, along the footwall of the ore body, the along-vein transport roadway 1 is arranged. During the construction process of the vein-along transport roadway 1, the vertical ore body direction is constructed at a distance of 30m. The construction of bottom-drawing roadway 5, along-vein transportation roadway 1 and vein-piercing ore-exiting roadway 2 in the later stope recovery process is completed, and air inlet and return passages and safety passages are formed. For ore body 6, a 25m×15m stope is arranged according to the occurrence of the ore body, and 4m of ore pillars 4 are reserved between the stopes. During the mining process, blasting mining is carried out with the bottom roadway 5 as the free-facing direction of the stope. First, the stope roof 7 is completely pulled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com