Device and process for spin-coating polymeric membrane on surface of optical fiber grid region and application

A technology of spin coating and polymer film, which is applied in the direction of cladding optical fiber, grating fiber, measuring device, etc., can solve the problems of harsh polymerization conditions and equipment requirements, difficulty in controlling the thickness of polymer film, and difficulty in obtaining performance sensors, etc., to achieve The effect of high coating process efficiency, excellent gas selectivity, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] In this embodiment, taking the coating of polyimide film on the surface of the optical fiber grating region as an example, the spin coating process is described.

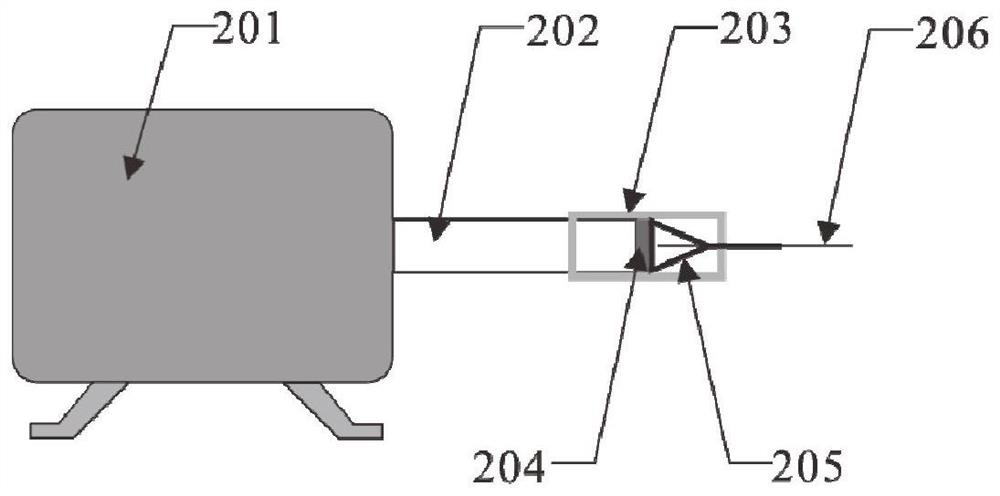

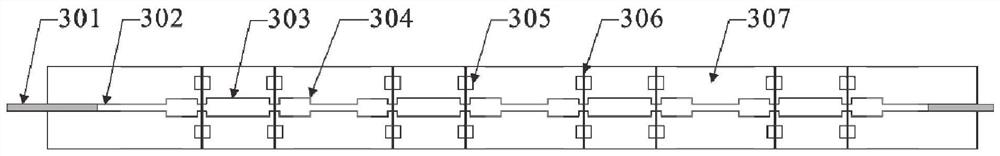

[0059] In this embodiment, the model of the low-speed motor (201) is 220V / 60KTYZ, the rotation speed is 5r / min, and the diameter of the rotating shaft is 7mm. First, the optical fiber (206) is fixed on the mold and connected with the low-speed motor (201) in a logical order on the platform support, wherein the selected optical fiber (206) is an optical fiber with four gate areas, so the selected mold is also Four grid area mould, mold length and solution tank (303) pitch are determined by fiber grating, and mold three-dimensional dimension is selected as 525mm * 25mm * 15mm, and the diameter of the optical fiber limiting groove (302) on the central axis of mold upper surface is 0.5mm, The solution tank (303) specification is 20mm * 5mm * 2.5mm, the size of the longitudinal anti-overflow tank (304) positioned ...

Embodiment 2

[0061] In this embodiment, taking the coating of polyethersulfone film on the surface of the optical fiber grating region as an example, the process of its spin coating is described.

[0062] In this embodiment, the model of the low-speed motor (201) is 220V / 60KTYZ, the rotation speed is 10r / min, and the diameter of the rotating shaft is 7mm. First, on the platform support, the optical fiber (206) is fixed on the mold and connected with the low-speed motor (201) in a logical order, wherein the selected optical fiber (206) is an optical fiber with six gate areas, so the selected mold is also The mold with six grid areas, the length of the mold and the distance between the solution grooves (303) are determined by the fiber grating, the three-dimensional size of the mold is selected as 540mm × 25mm × 15mm, and the diameter of the optical fiber limiting groove (302) on the central axis of the upper surface of the mold is 0.5mm. The solution tank (303) specification is 20mm * 5mm *...

Embodiment 3

[0064] In this embodiment, the coating of polyimide films with different thicknesses on the multi-gate optical fiber is taken as an example, and the spin coating process thereof is described.

[0065] In this embodiment, the model of the low-speed motor (201) is 220V / 60KTYZ, the rotation speed is 5r / min, and the diameter of the rotating shaft is 7mm. First, the optical fiber (206) is fixed on the mold and connected with the low-speed motor (201) in a logical order on the platform support, wherein the selected optical fiber (206) is an optical fiber with four gate areas, so the selected mold is also The four-gate area mold, the length of the mold and the distance between the solution tanks (303) are determined by the fiber grating, the three-dimensional size of the mold is selected as 525mm × 25mm × 15mm, and the diameter of the optical fiber limiting groove (302) on the central axis of the upper surface of the mold is 0.5mm , the solution tank (303) specification is 20mm * 5mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com