Gas dynamic pressure bearing, motor and fan motor

A gas dynamic pressure bearing, axial technology, applied in the direction of sliding contact bearings, rotating bearings, bearings, etc., can solve problems such as inability to ensure space, achieve the effect of reducing vibration or noise, and stabilizing air volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

[0022]

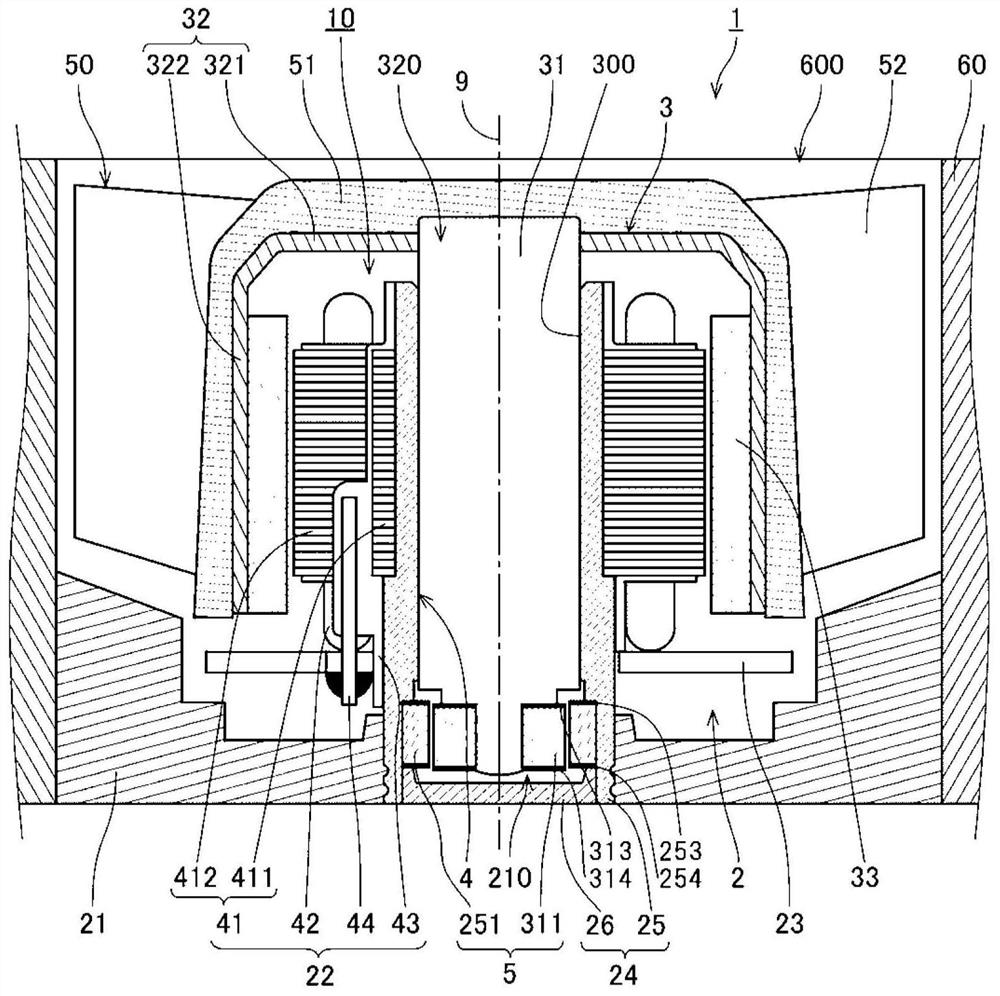

[0023] The fan motor 1 according to the first embodiment of the present invention is mounted, for example, inside a housing of a personal computer, and is used as a device for supplying cooling air flow. However, the fan motor 1 can also be used as a device for supplying air flow for cooling to a space such as a home appliance such as a refrigerator, a high-temperature device such as a vehicle headlight, or a server system in which a plurality of electronic devices are arranged. figure 1 It is a vertical cross-sectional view of the fan motor 1 according to the first embodiment of the present invention. Such as figure 1 As shown, the fan motor 1 has a motor 10 , an impeller 50 and a housing 60 .

[0024]

[0025] Next, the structure of the motor 10 will be described. The motor 10 is a device that rotates the impeller 50 according to a driving current. Such as figure 1 As shown, the motor 10 has a stationary part 2 and a rotating part 3 . The stationary part 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com