Ultraviolet lamp light curing pipeline repairing method

A technology of pipeline repair and ultraviolet light, which is applied in the direction of special pipes, pipe components, pipes/pipe joints/pipe fittings, etc., can solve the problems affecting underground pipelines around municipal traffic, etc., and achieve short molding stability time, high material strength, and low noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

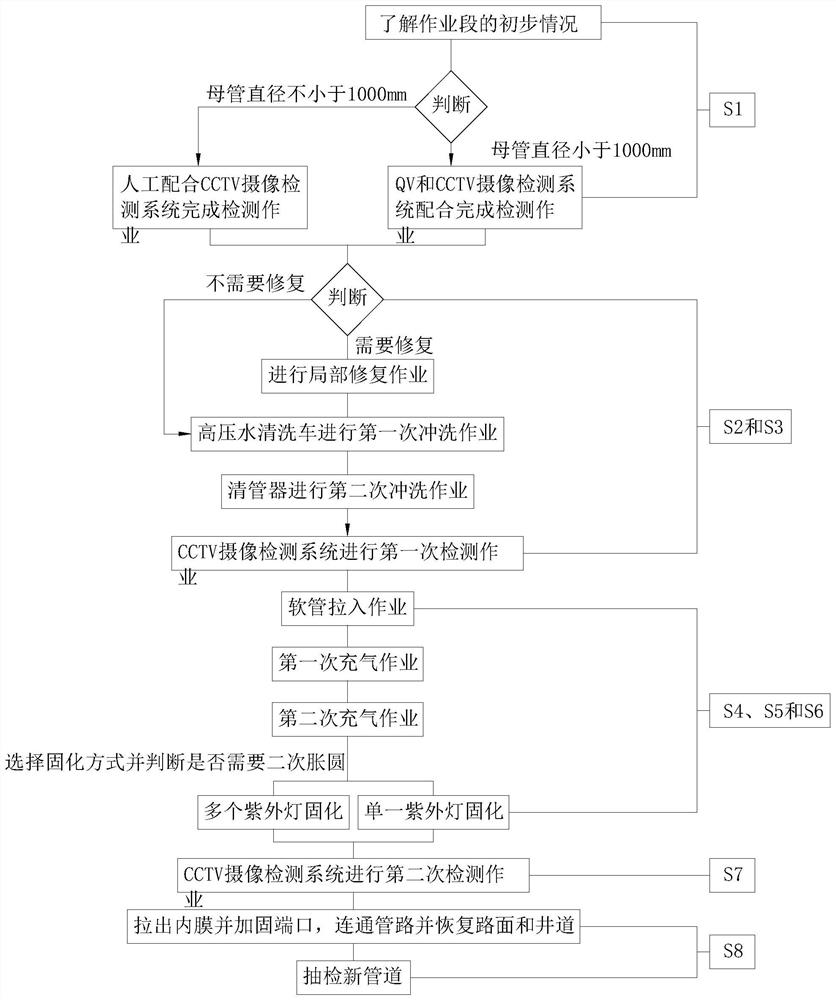

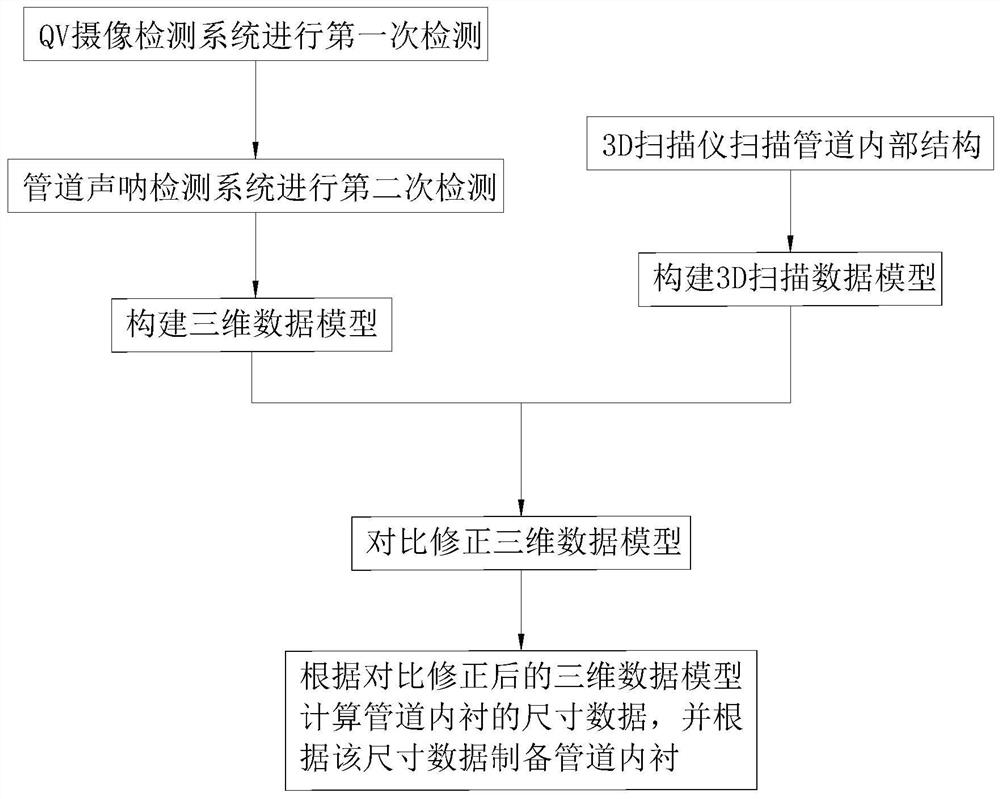

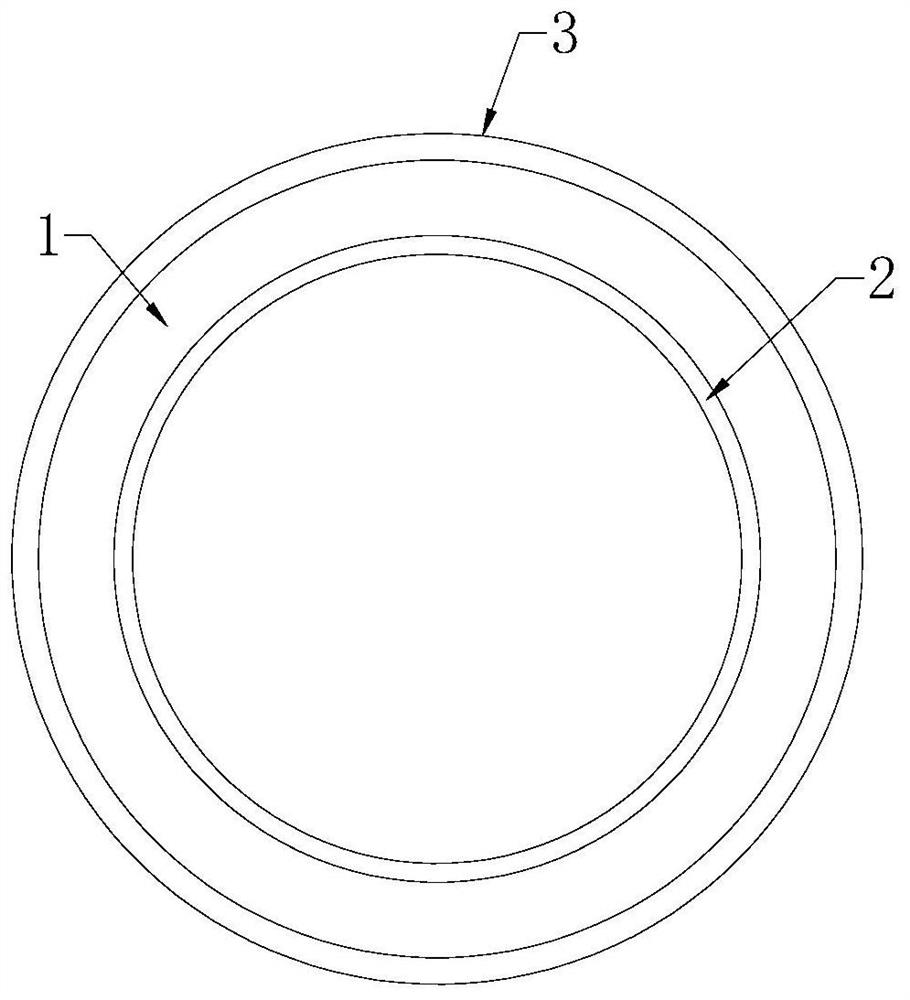

[0036] A method for repairing pipelines cured by ultraviolet light. The construction personnel first need to determine the location and specific data of the old pipelines, prepare the lining of the pipelines, and then perform cleaning and testing operations on the old pipelines, so that the old pipelines (hereinafter collectively referred to as the mother pipe) The inner wall of the inner wall and the internal conditions of the main pipe meet the construction requirements; then use the pipe lining (hereinafter collectively referred to as the hose) soaked with UV-curable resin, and cure with the main pipe to form an integrated pipe-in-pipe structure; finally inspect, accept and repair The final new pipeline (that is, the pipe-in-pipe structure formed by the hose and the parent pipe) and restore the road surface to complete the pipeline repair work. The pipelin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com