CIPP trenchless pipeline repair method

A pipeline repair, trenchless technology, applied in the direction of special pipes, pipe components, pipes/pipe joints/fittings, etc., can solve problems such as affecting the underground pipelines around municipal traffic, and achieve changes in flow, high intensity and short construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

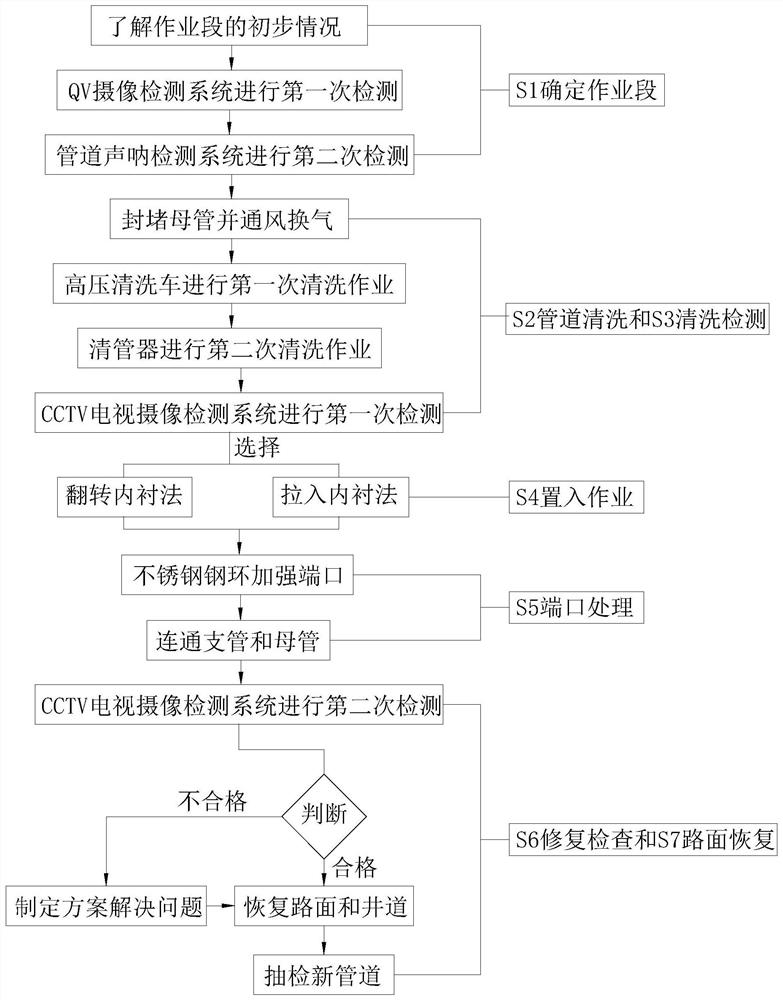

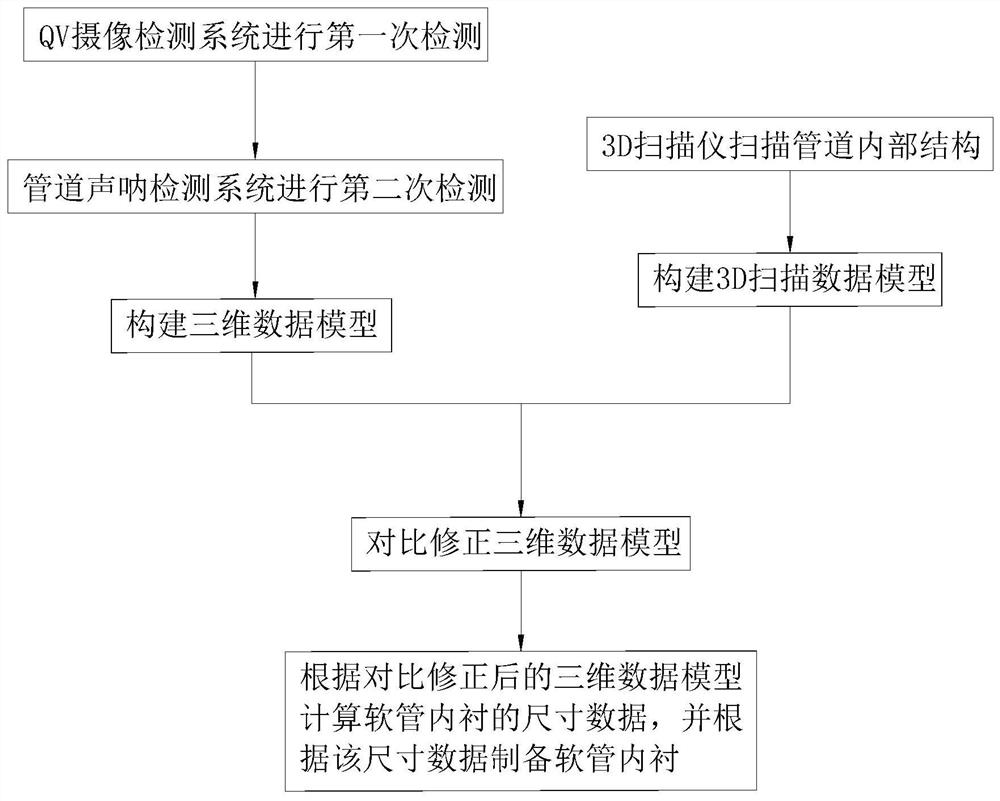

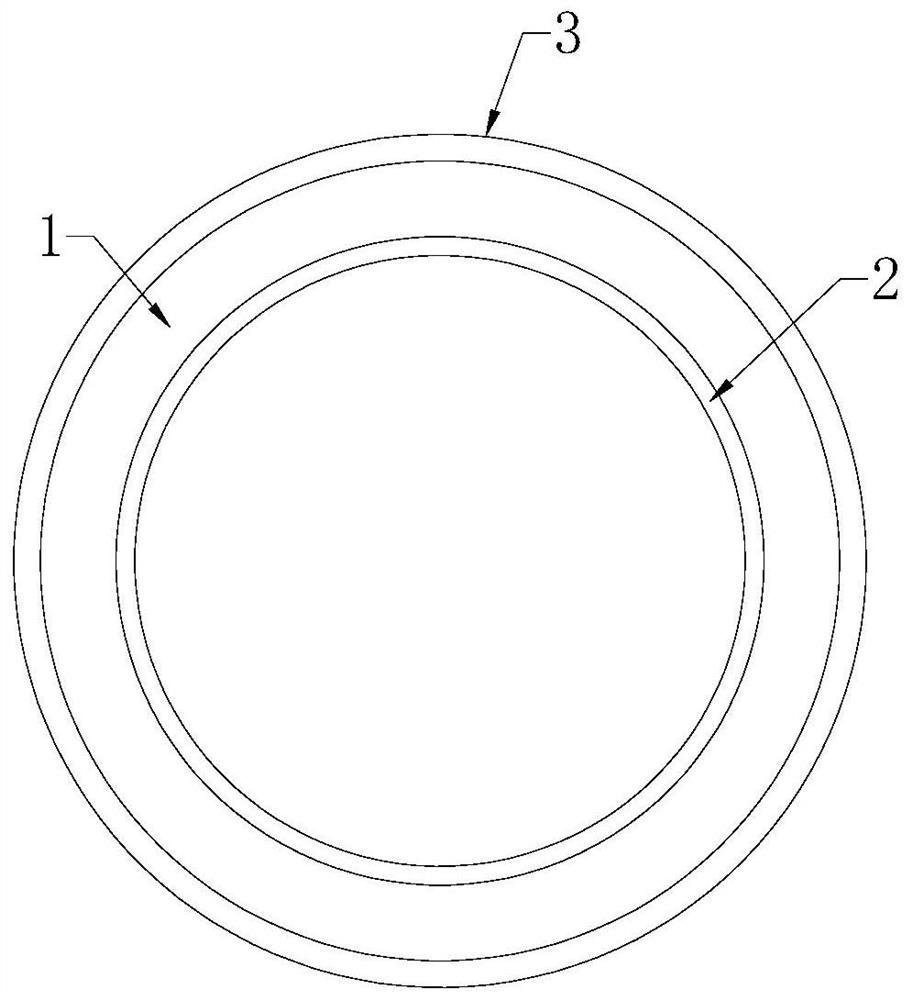

[0035] A CIPP trenchless pipeline repair method, the construction personnel first need to determine the operation section and prepare the hose lining according to the test data, and then perform pipeline cleaning and pipeline inspection operations, so that the inner wall of the parent pipe (that is, the pipeline to be repaired) and the inner wall of the parent pipe The internal conditions of the pipe are combined with the construction requirements; then the hose lining soaked in thermosetting resin is tightly combined with the parent pipe to form a pipe-in-pipe structure, and the end of the hose lining is smoothed; finally, the repaired new pipeline (ie The pipe-in-pipe structure formed by the hose lining and the parent pipe) is inspected and accepted and the road surface is restored, thereby completing the non-excavation pipeline repair operation. The CIPP n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com