A cold mounting tool and method for multiple fiber monofilaments

A cold inlay and fiber technology, applied in the field of materials, can solve the problems of multiple monofilament impact, fiber monofilament breakage, difficult positioning, etc., and achieve the effect of ensuring accuracy, small fiber damage, and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a cold setting tool for multiple fiber monofilaments and a cold setting method using the cold setting tool.

[0039] Cold mounting tools include V-groove fiber parallel mounts and multi-antenna supports.

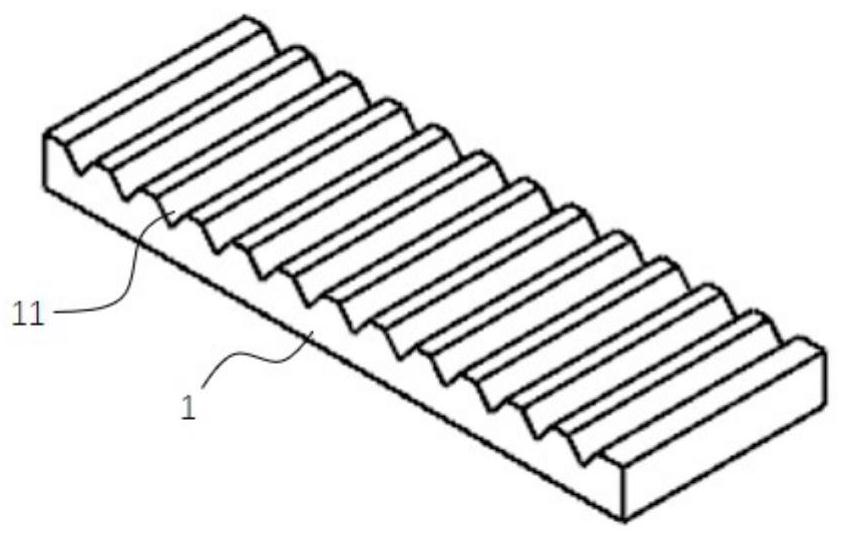

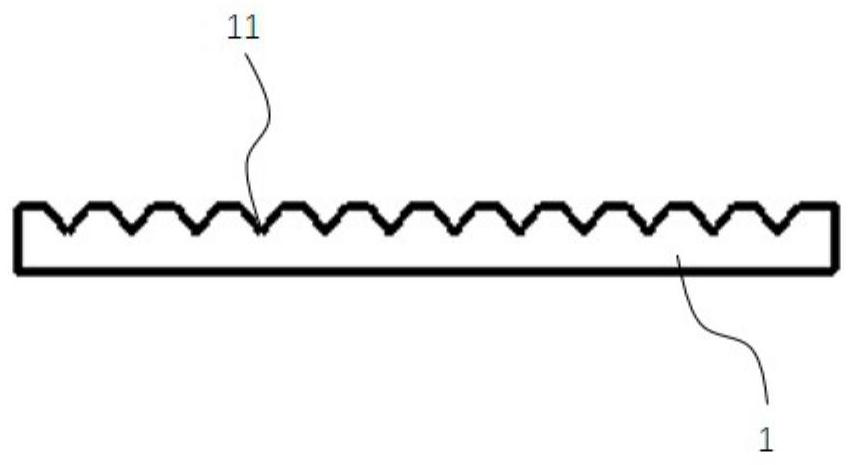

[0040] Such as Figure 1a with 1b As shown, the V-shaped groove fiber parallel seat 1 is a rectangular plate body with several V-shaped grooves 11 on the upper surface. The V-shaped grooves 11 are strip-shaped, arranged along the width direction of the rectangular plate body, extending from one side of the rectangular plate body to the other side, and several V-shaped grooves 11 are parallel to each other. The groove section of the V-shaped groove 11 is V-shaped, and can accommodate fiber monofilaments (non-lengthwise direction) in the plane direction of the groove section.

[0041] The V-groove fiber parallel seat 1 is made of a bendable material, specifically, a resin material.

[0042] Bend the V-shaped groove fiber parallel seat 1 so th...

Embodiment 2

[0067] This embodiment provides a cold setting tool for multiple fiber monofilaments and a cold setting method using the cold setting tool. Wherein, the structure of the cold mounting tool is the same as that of Example 1; in the cold mounting method for multiple fiber monofilaments, the multiple fiber monofilaments are multiple different fiber monofilaments in the fiber bundle. The method includes the following steps:

[0068] Step 1, preparing fiber monofilaments, including the following specific steps:

[0069] S1. Soak the fiber bundle in an organic solvent, sonicate and heat at the same time.

[0070] Specifically, put SiC fiber bundles with a length of 15 cm into a beaker with a diameter of 77 cm, a height of 107 cm, and a cup mouth diameter of 85 cm, and pour absolute ethanol until the fiber bundles are covered; pour clean water into an ultrasonic cleaner and heat to 35°C, put the beaker into a washing machine, the capacity of the ultrasonic washing machine is 3.2 lit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com