Full-automatic magnetic powder flaw detection equipment

A magnetic particle flaw detection, fully automatic technology, applied in the direction of material magnetic variables, measuring devices, instruments, etc., can solve the problems of increasing the workload of the staff, improving the magnetic particle flaw detection, etc., to reduce physical injuries, avoid contact with magnetic particles, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Embodiment: A fully automatic magnetic particle flaw detection equipment, including a flaw detector control system, a camera module connected to the flaw detector control system, and a remote computer connected to the flaw detector control system with a network;

[0042] The flaw detector control system is used to store the following instructions:

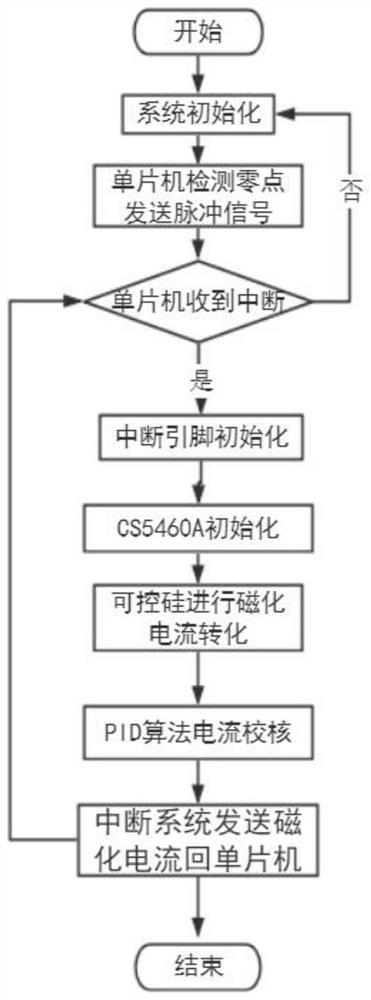

[0043] flaw detection:

[0044] Control the angle of the thyristor, and find the target potential through the current comparison of different periods;

[0045] like figure 1 As shown in the flaw detection work flow chart, the flaw detector control system includes a single-chip microcomputer. After the flaw detector control system package is initialized, the single-chip microcomputer detects the zero point and sends a pulse signal, and then the single-chip microcomputer interrupts. If the single-chip microcomputer interrupt signal is received, the interrupt pin is initialized. , if the initialization of the MCU interrupt pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com