Chip temperature control test board and temperature control test method thereof

A test bench and chip technology, applied in the field of machining and chip testing, can solve the problems of test parameter interference, influence, water vapor condensation, etc., to achieve the effect of temperature and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

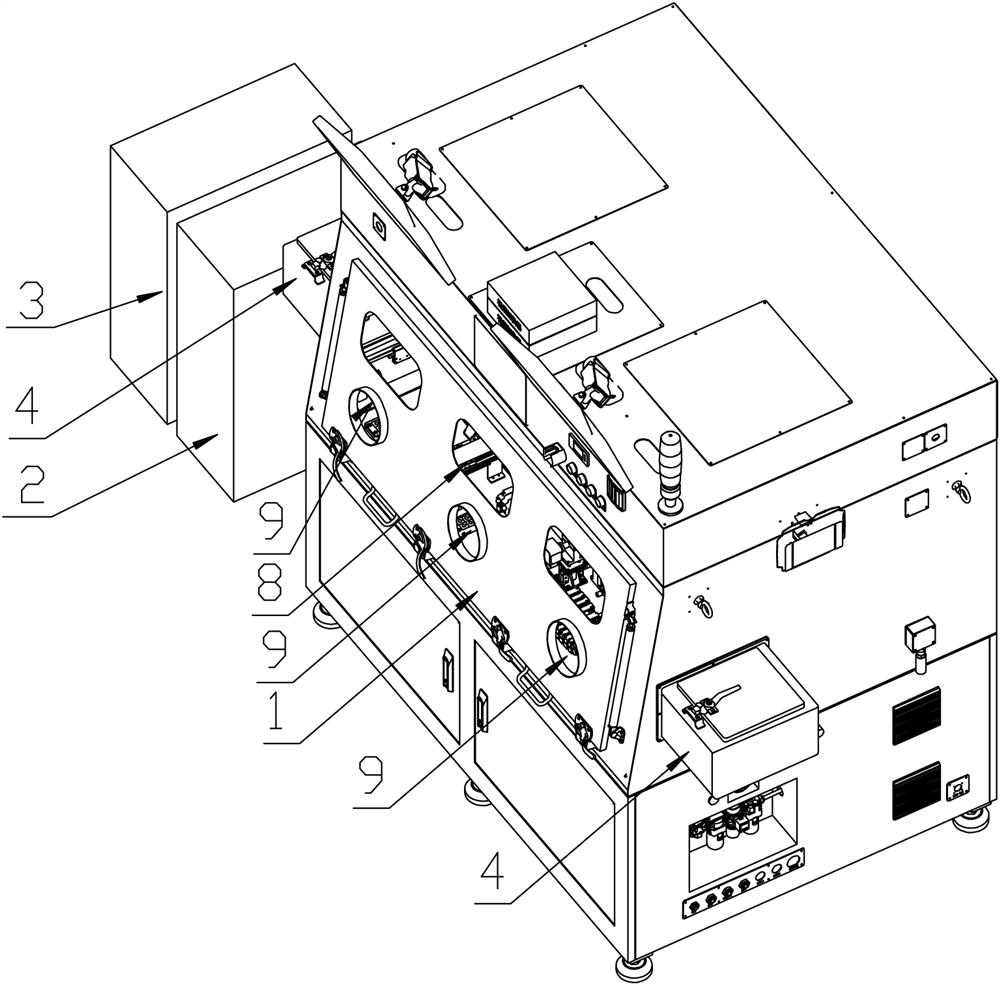

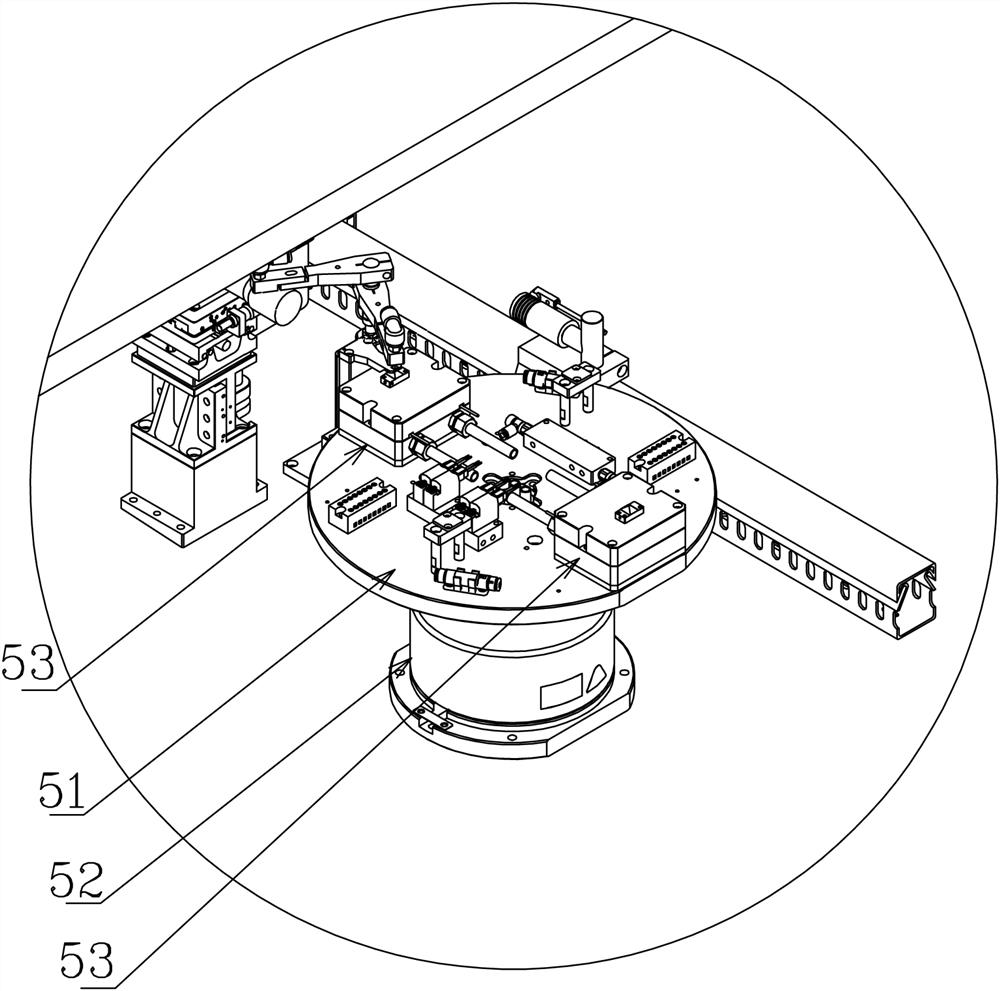

[0033] Such as Figure 1~4 As shown, a chip temperature control test bench includes an operating table arranged on a frame, a sealed cabin 1 is arranged on the operating table, and a drying mechanism 2 and a cooling mechanism 3 connected with the sealed cabin 1 are arranged at one end of the sealed cabin 1 , the sealed cabin 1 is provided with a testing mechanism 5,

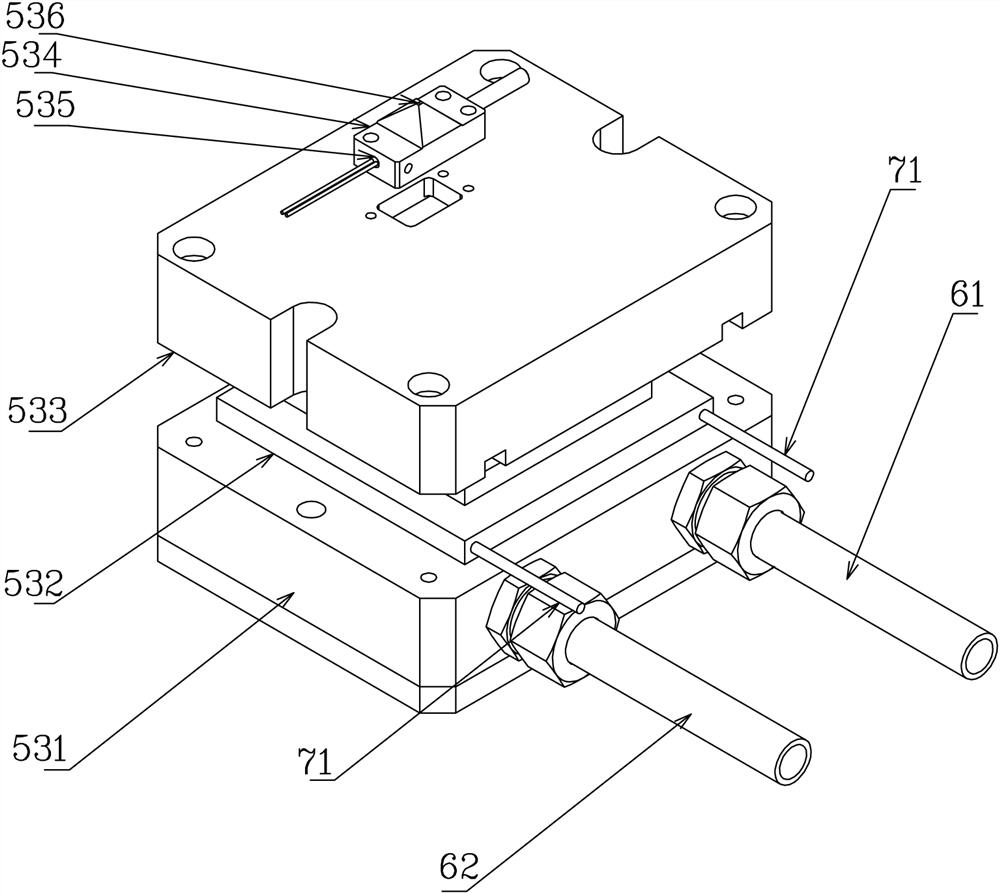

[0034] Specifically, the testing mechanism 5 includes a rotating seat 52 arranged in the airtight chamber 1 , on which a turntable 51 is driven, and two groups of temperature-controlled test benches 53 are arranged on the turntable 51 . The temperature control test bench 53 includes a temperature control device arranged in the airtight cabin 1, the temperature control device includes a cooling plate 531 arranged on the turntable 51, a heating plate 532 is arranged on the cooling plate 531; a heat insulating plate is arranged on the heating plate 532 533 , a test carrier 534 is set on the heat shield 533 , and a ...

Embodiment 2

[0037] A temperature control test method for a chip temperature control test bench 53:

[0038]Step 1, adjust the monitoring environment of the airtight cabin 1; adjust the ambient temperature and humidity of the airtight cabin 1 through the drying mechanism 2 and the cooling mechanism 3 respectively, and set an isolation chamber at the inlet and outlet of the airtight cabin 1 respectively 4. Prevent the air in the external environment from directly entering the airtight chamber 1 without drying and temperature control regulation, thereby affecting the test temperature and test environment of the temperature control test bench 53;

[0039] Step 2, adjust the temperature of the temperature control test bench 53; through the cooling plate 531 and the heating plate 532 in the temperature control device, comprehensively control and adjust the temperature of the temperature control test bench 53, so that the temperature of the temperature control test bench 53 is constant at the set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com