On-line soft measurement method and device for calorific value of raw coal fed into coal-fired boiler

A coal-fired boiler and soft measurement technology, which is applied in the fields of measurement and testing, combustion and combustion equipment, can solve the problem of non-real-time calculation, achieve high real-time performance, improve real-time performance, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] An online soft measurement method for the calorific value of raw coal fed into a coal-fired boiler, comprising the steps of:

[0042] Step 1, collect boiler operation data, and preprocess the boiler operation data;

[0043] The boiler operation data includes: the total air volume of the boiler operation, the total coal volume of the boiler operation, the oxygen volume of the boiler operation, and the negative pressure of the furnace (optional);

[0044] The total air volume of boiler operation refers to the sum of primary air volume and secondary air volume of each coal mill; the total coal volume of boiler operation refers to the sum of coal feeding volume of each coal feeder.

[0045] The method of collecting boiler operation data includes: collecting the boiler operation data by the meter installed on site, accessing the analog signal of each parameter, or obtaining the boiler operation data from the data acquisition system or the relevant database of the plant-level...

Embodiment 2

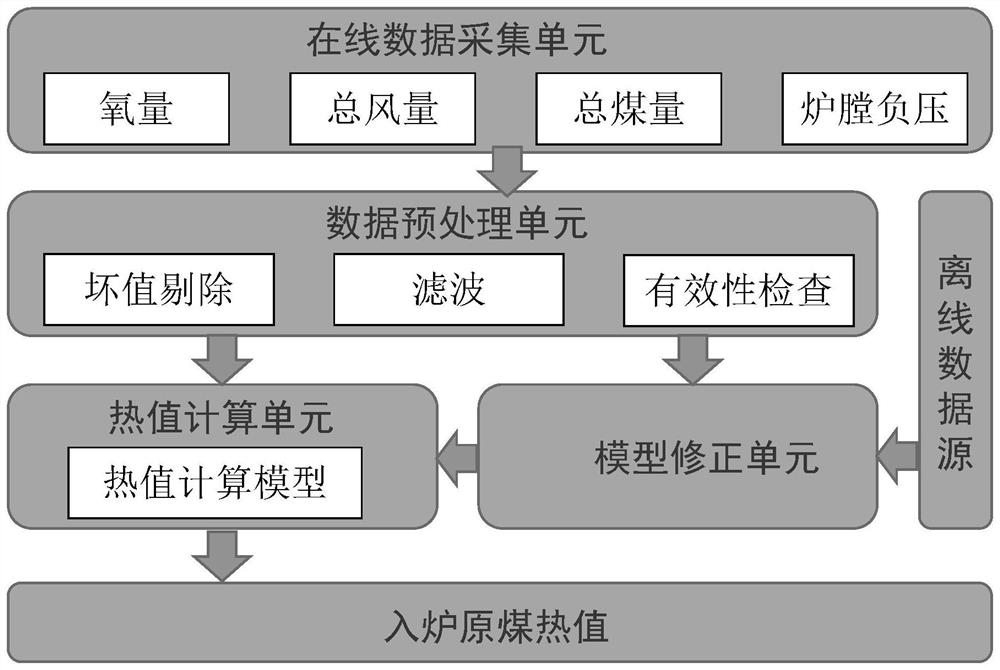

[0062] An online soft measuring device for the calorific value of raw coal fed into a coal-fired boiler, comprising:

[0063] Online data acquisition unit for collecting boiler operation data;

[0064] The data preprocessing unit is used to preprocess the boiler operation data;

[0065] The calorific value calculation unit is used to calculate the high-level calorific value of the coal-fired boiler into the furnace based on the pre-processed boiler operation data and the received base calorific value of the coal-fired boiler; The multiple relationship of the raw coal received base low calorific value;

[0066] The model correction unit is used to correct the calculation model.

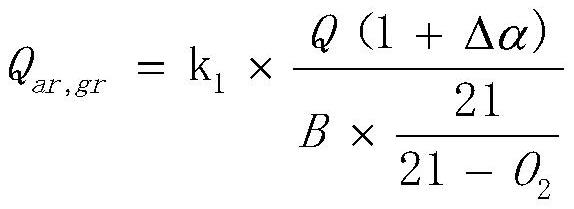

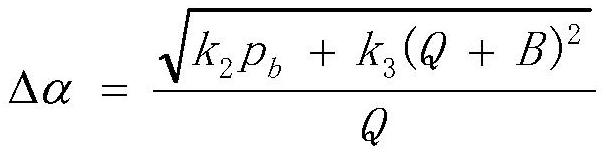

[0067] Further, the calculation model is:

[0068]

[0069] Of which: Q ar,gr is the received base high calorific value of raw coal, MJ / kg; Q is the total air volume of boiler operation, t / h; B is the total coal volume of boiler operation, t / h; O 2 is the oxygen amount of boiler operation, %; Δ...

Embodiment 3

[0071] In order to compare the difference between the calculated result and the actual calorific value, this embodiment uses data of several stable working conditions.

[0072] An online soft measurement method for the calorific value of raw coal fed into a coal-fired boiler, comprising the steps of:

[0073] Step 1, collect boiler operation data, and preprocess the boiler operation data;

[0074] The total air volume, total coal volume, and oxygen volume data of the boiler are collected. The data collected under each working condition are preprocessed as shown in Table 1. The data listed in Table 1 is the average value of each working condition, which can be considered to be filtered by the average value. data, and in addition to oxygen, total air and total coal volumes have been preprocessed from the raw measurements.

[0075] The total air volume of the boiler is the sum of the primary air volume and the secondary air volume of each coal mill during the operation of the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com