Method for reducing polarization of lithium battery

A lithium battery, reduction technology, applied in secondary batteries, electrochemical generators, secondary battery charging/discharging, etc., can solve problems affecting the performance of positive and negative electrodes of batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

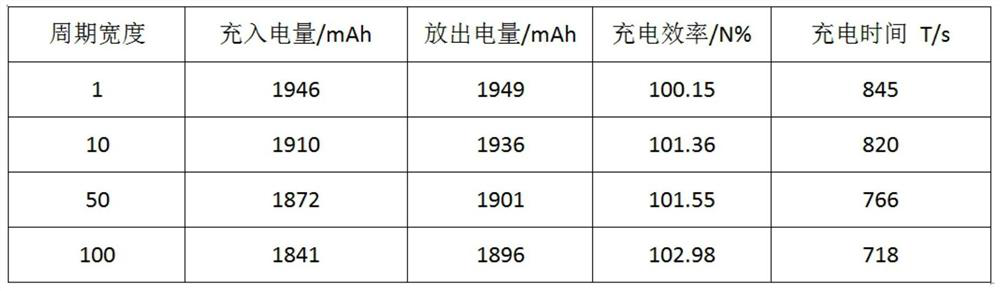

Embodiment 1

[0019] A method for reducing polarization of lithium batteries:

[0020] S1. Discharge the lithium battery to a discharge cut-off voltage of 2.5V;

[0021] S2. In an environment with a temperature of 25 degrees Celsius, charge the lithium battery with positive and negative pulses to the charge cut-off voltage of 4.2V. In the positive and negative pulse charging mode, the positive pulse width is 9 seconds, the negative pulse width is 1 second, and the positive and negative pulses The pulse amplitude in the charging mode is equal to the charging magnification of the constant current charging mode, the period width of the positive and negative pulses is 1s, and the charging time is recorded;

[0022] S3. Place the charged lithium battery for 50 minutes so that the surface temperature of the lithium battery is the same as the ambient temperature;

[0023] S4. Perform constant current discharge on the lithium battery under the condition of an average charge rate of 03C, and record the amou...

Embodiment 2

[0025] A method for reducing polarization of lithium batteries:

[0026] S1. Discharge the lithium battery to a discharge cut-off voltage of 2.5V;

[0027] S2. In an environment with a temperature of 25 degrees Celsius, charge the lithium battery with positive and negative pulses to the charge cut-off voltage of 4.2V. In the positive and negative pulse charging mode, the positive pulse width is 9 seconds, the negative pulse width is 1 second, and the positive and negative pulses The pulse amplitude in the charging mode is equal to the charging rate of the constant current charging mode, the period width of the positive and negative pulses is 10s, and the charging time is recorded;

[0028] S3. Place the charged lithium battery for 55 minutes so that the surface temperature of the lithium battery is the same as the ambient temperature;

[0029] S4. Perform constant current discharge on the lithium battery under the condition of an average charge rate of 3C, and record the amount of ele...

Embodiment 3

[0031] A method for reducing polarization of lithium batteries:

[0032] S1. Discharge the lithium battery to a discharge cut-off voltage of 2.5V;

[0033] S2. In an environment with a temperature of 25 degrees Celsius, charge the lithium battery with positive and negative pulses to the charge cut-off voltage of 4.2V. In the positive and negative pulse charging mode, the positive pulse width is 9 seconds, the negative pulse width is 1 second, and the positive and negative pulses The pulse amplitude in the charging mode is equal to the charging magnification of the constant current charging mode, the cycle width of the positive and negative pulses is 50s, and the charging time is recorded;

[0034] S3. Place the charged lithium battery for 60 minutes so that the surface temperature of the lithium battery is the same as the ambient temperature;

[0035] S4. Perform constant current discharge on the lithium battery under the condition of an average charge rate of 3C, and record the amoun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com