Carbon fiber-loaded magnesium oxide particle crosslinked nanosheet array composite material and its preparation method and application

A technology of magnesium oxide particles and nanosheet arrays, applied in electrochemical generators, structural parts, electrical components, etc., can solve problems such as difficulty in playing a three-dimensional carrier role, and achieve a reduction in limited current density, low polarization voltage, and enhanced affinity. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

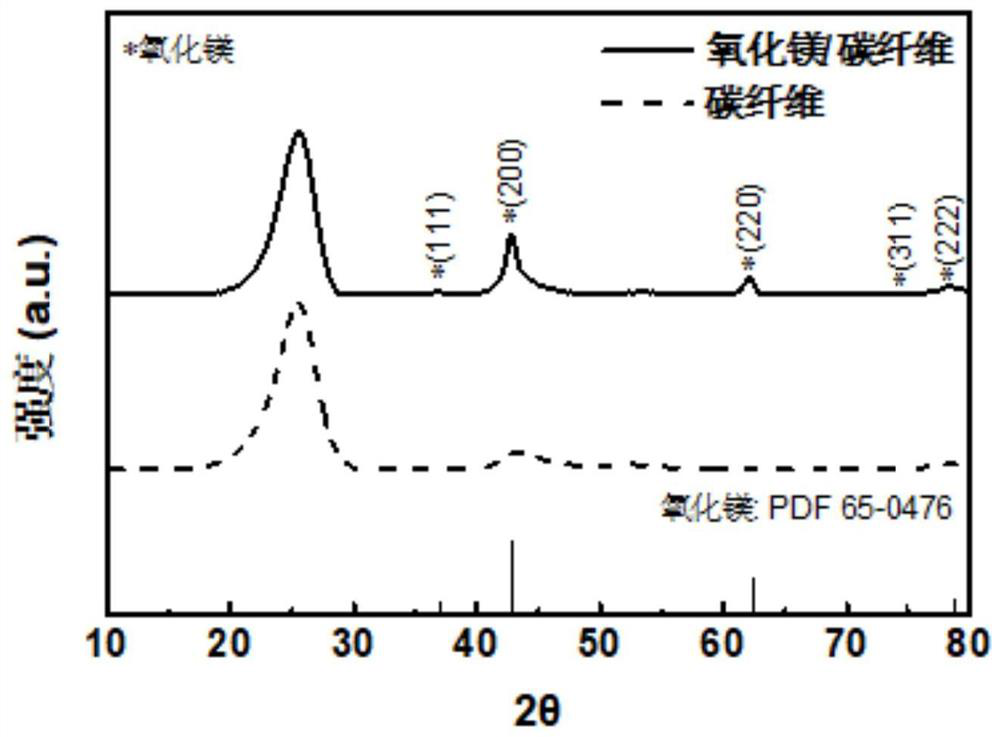

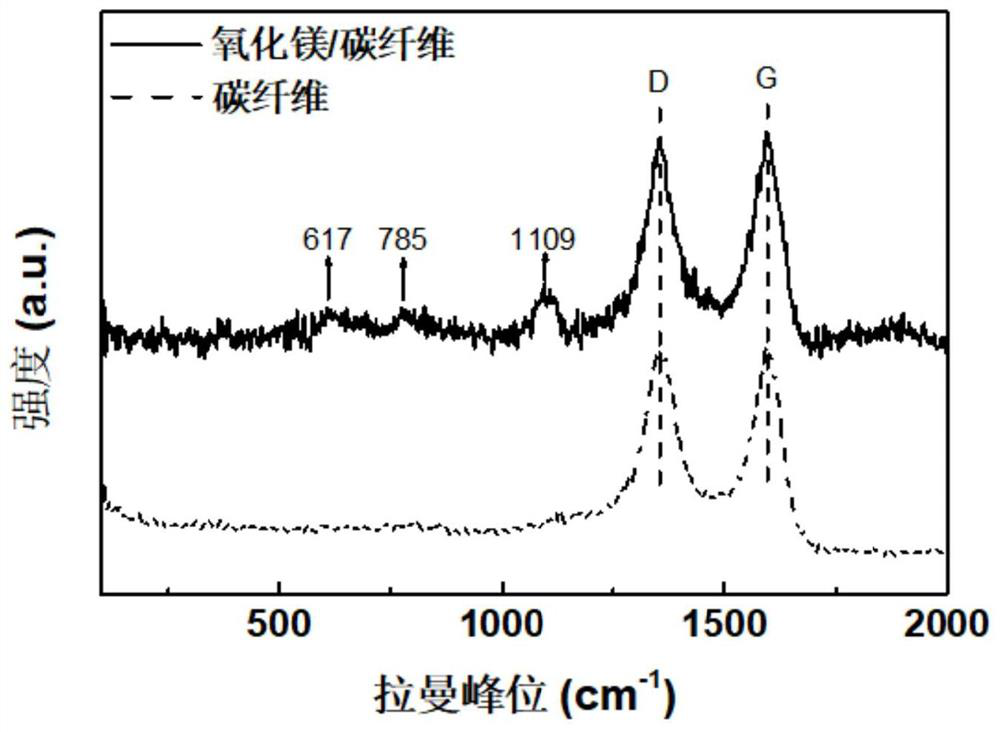

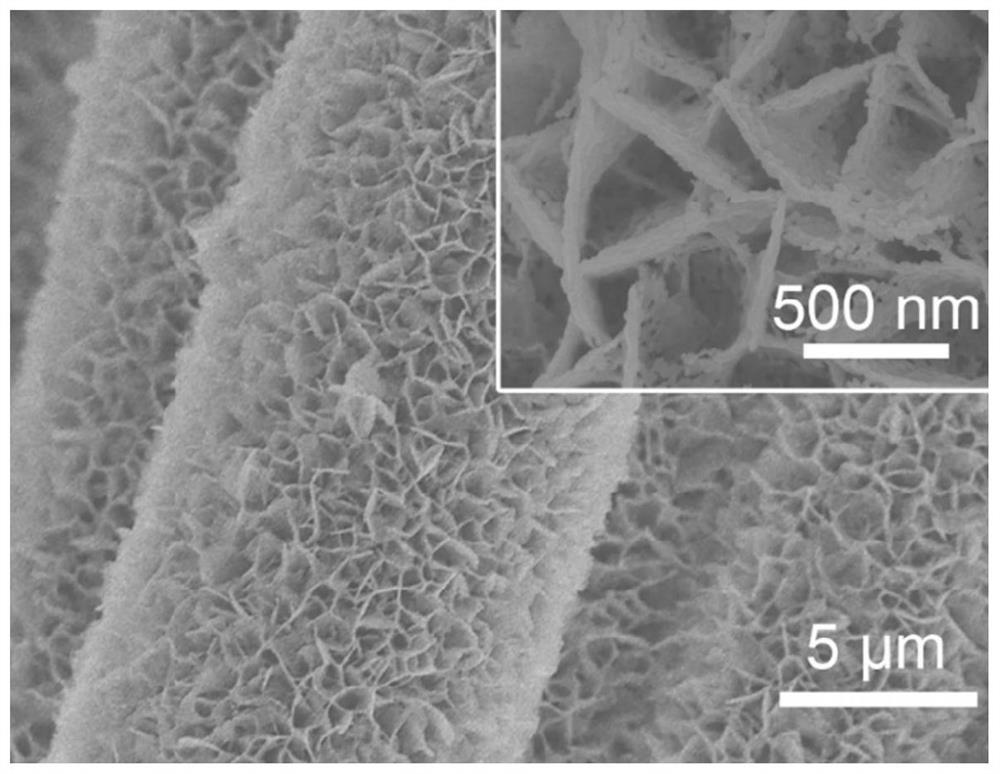

Embodiment 1

[0041] The 2cm*3cm carbon fibers were cleaned with acetone, ethanol and deionized water in an ultrasonic cleaner for 15 minutes, and then placed in an oven at 60°C for 24 hours to dry. The dry and clean carbon fiber is subjected to vacuum plasma surface treatment for 20 minutes to obtain a hydrophilic carbon fiber with a large amount of oxygen-containing groups on the surface. The hydrophilic carbon fiber is used as the working electrode, the platinum electrode is used as the counter electrode / reference electrode, and Mg is prepared with deionized water. 2+ The concentration is 0.5mol L -1 Magnesium nitrate solution is used as the electrolyte, at room temperature 25 ℃, with 4mA cm -2 The constant current cathodic deposition was carried out at the current density to obtain the carbon fiber supported magnesium hydroxide composite material. After cleaning with deionized water, heat to 400°C in the air, and heat treatment for 1 h to obtain carbon cloth-supported magnesium oxide ...

Embodiment 2

[0047] The 2cm*3cm carbon fibers were cleaned with acetone, ethanol and deionized water in an ultrasonic cleaner for 15 minutes, and then placed in an oven at 60°C for 24 hours to dry. The dry and clean carbon fiber is subjected to vacuum plasma surface treatment for 20 minutes to obtain a hydrophilic carbon fiber with a large amount of oxygen-containing groups on the surface. The hydrophilic carbon fiber is used as the working electrode, the platinum electrode is used as the counter electrode / reference electrode, and Mg is prepared with deionized water. 2+ The concentration is 0.3mol L -1 Magnesium nitrate solution is used as the electrolyte, at room temperature 25 ℃, with 4mA cm -2 The constant current cathodic deposition was carried out at the current density to obtain the carbon fiber supported magnesium hydroxide composite material. After cleaning with deionized water, heat to 400° C. in air, and heat treatment for 1 h to obtain a carbon cloth-loaded magnesium oxide com...

Embodiment 3

[0049] The 2cm*3cm carbon fibers were cleaned with acetone, ethanol and deionized water in an ultrasonic cleaner for 15 minutes, and then placed in an oven at 60°C for 24 hours to dry. The dry and clean carbon fiber is subjected to vacuum plasma surface treatment for 20 minutes to obtain a hydrophilic carbon fiber with a large amount of oxygen-containing groups on the surface. The hydrophilic carbon fiber is used as the working electrode, the platinum electrode is used as the counter electrode / reference electrode, and Mg is prepared with deionized water. 2+ The concentration is 0.4mol L -1 Magnesium nitrate solution is used as the electrolyte, at room temperature 25 ℃, with 4mA cm -2 The constant current cathodic deposition was carried out at the current density to obtain the carbon fiber supported magnesium hydroxide composite material. After cleaning with deionized water, heat to 400° C. in air, and heat treatment for 1 h to obtain a carbon cloth-loaded magnesium oxide com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com