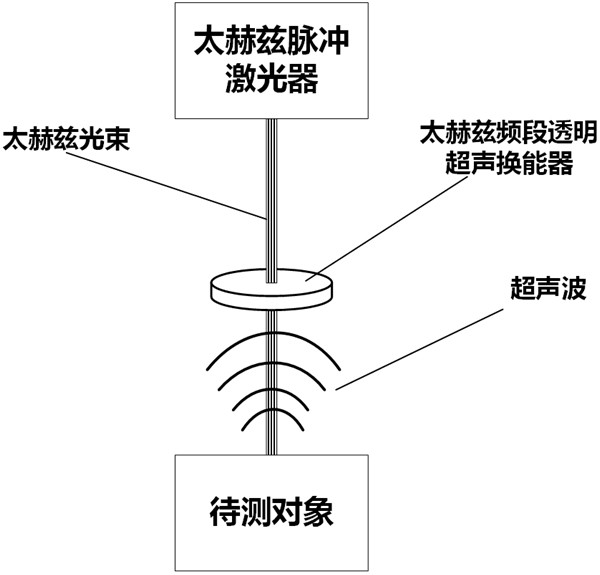

Terahertz-frequency-band transparent piezoelectric film, ultrasonic transducer and preparation method of terahertz-frequency-band transparent piezoelectric film

A technology of ultrasonic transducer and piezoelectric film, which is applied in the field of terahertz photoacoustic imaging, can solve problems such as laser transmission obstruction, and achieve the effects of improving clarity, transparency, and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation method of the transparent piezoelectric film in the terahertz frequency band provided in this embodiment includes:

[0048] (1) The transparent polymethylpentene in the terahertz band is heated to a molten state;

[0049] (2) Add ≤4 layers of graphene transparent in the terahertz band to the molten polymethylpentene obtained in the above step (1) as a conductive doping phase, and add PMN-PT with a particle size of ≤5 μm, that is, graphite Both alkene and PMN-PT are dispersed in the polymethylpentene base in the molten state in a 0-dimensional manner, and the three are stirred while the polymethylpentene is in a molten state to make the dispersion uniform to obtain PMN-PT / graphite. ene / polymethylpentene composite solution;

[0050] Among them, the melting point of the inorganic piezoelectric material PMN-PT and ≤4-layer graphene transparent in the terahertz band as a doping phase should be higher than the melting point of polymethylpentene to ensure that...

Embodiment 2

[0058] The preparation method of the transparent piezoelectric film in the terahertz frequency band provided in this embodiment includes:

[0059] (1) The transparent polymethylpentene in the terahertz band is heated to a molten state;

[0060] (2) Add ≤4 layers of graphene transparent in the terahertz band to the molten polymer material obtained in the above step (1) as a conductive doping phase, and add PMN-PT with a particle size of ≤5 μm, that is, graphene, PMN-PT is dispersed in the polymethylpentene substrate in a molten state in a 0-dimensional manner, and the three are stirred while the polymethylpentene is in a molten state to make the dispersion uniform to obtain PMN-PT / graphene / Polymethylpentene composite solution;

[0061] (3) The solution obtained in the above step (2) is hot-pressed and cured into a PMN-PT / graphene / polymethylpentene composite piezoelectric film, and the final proportion of each component is PMN-PT 35wt%, polymethyl pentene Pentene 60wt%, graph...

Embodiment 3

[0068] The preparation method of the transparent piezoelectric film in the terahertz frequency band provided in this embodiment includes:

[0069] (1) The transparent polymethylpentene in the terahertz band is heated to a molten state;

[0070] (2) Add ≤4 layers of graphene transparent in the terahertz band to the molten polymer material obtained in the above step (1) as a conductive doping phase, and add PMN-PT with a particle size of ≤5 μm, that is, graphene, PMN-PT is dispersed in the polymethylpentene substrate in a molten state in a 0-dimensional manner, and the three are stirred while the polymethylpentene is in a molten state to make the dispersion uniform to obtain PMN-PT / graphene / Polymethylpentene composite solution;

[0071] (3) The solution obtained in the above step (2) is hot-pressed and cured into a PMN-PT / graphene / polymethylpentene composite piezoelectric film, and the final proportion of each component is PMN-PT 50wt%, polymethyl pentene Pentene 35wt%, graph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com