High-strength C-shaped bridge

A high-strength, bridge technology, applied in the direction of electrical components, can solve the problems of increased cost and manufacturing difficulty, low strength and load, unfavorable transportation and laying, etc., to facilitate independent or combined laying, save material consumption, and improve service life and the effect of the operating safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

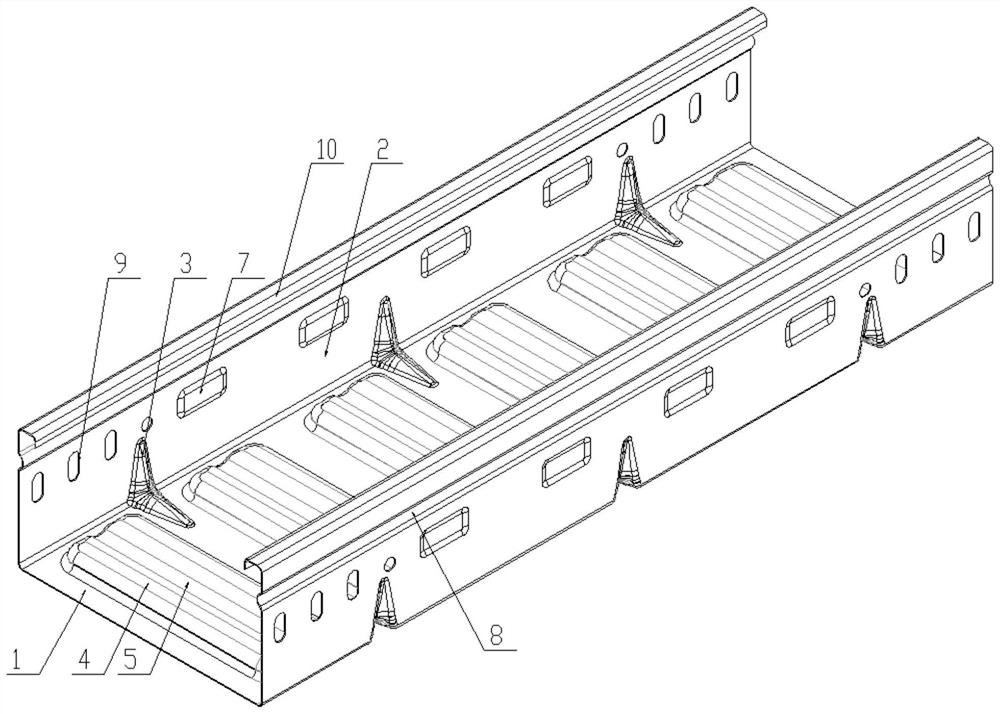

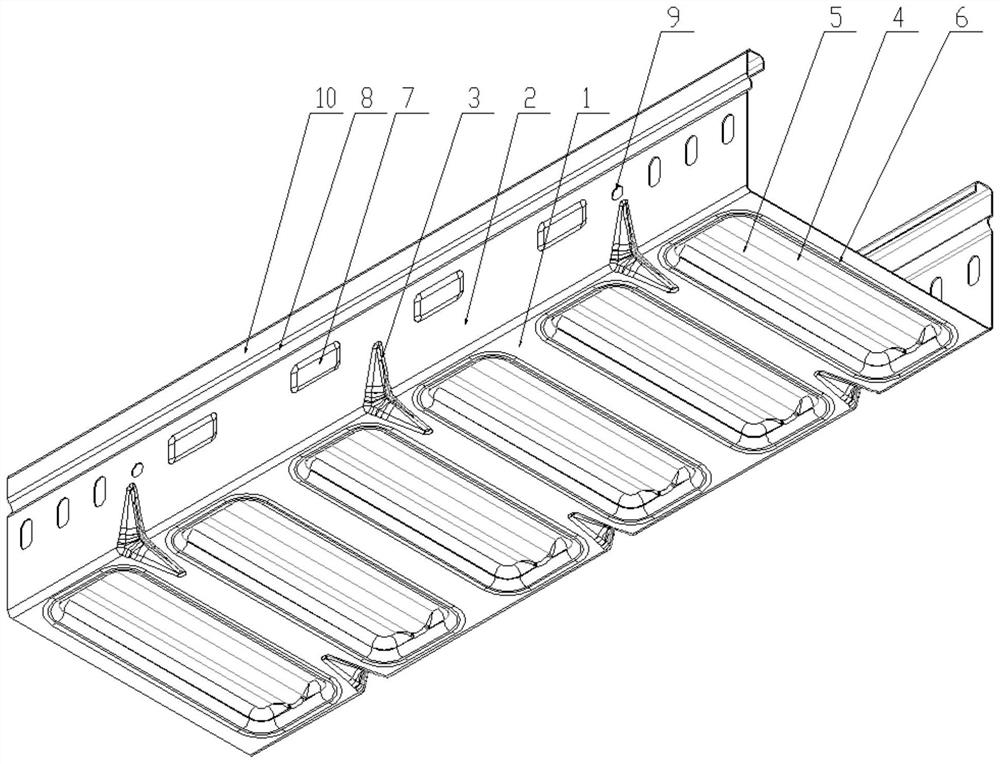

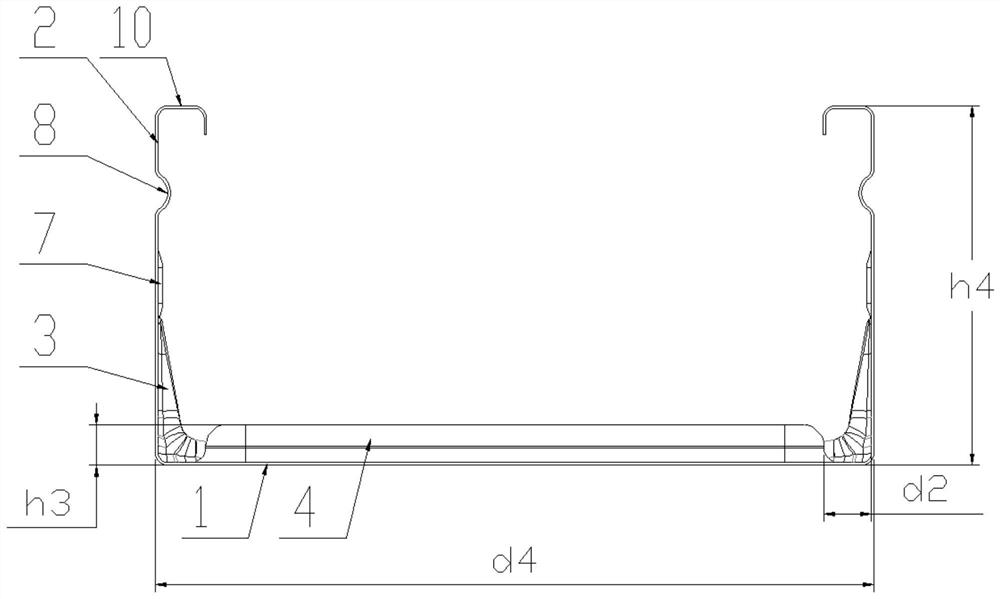

[0028] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0029] A high-strength C-shaped bridge frame includes a bottom profile 1 in an integrated C-shaped structure and a side profile 2 with both ends of the bottom profile 1 perpendicular to each other, wherein a number of spacings are arranged between the bottom profile 1 and the side profile 2, A corner convex hull 3 protruding to the inside of the bottom profile 1 and the side profile 2 is on the vertical surface of the bottom profile 1 and the side profile 2 and has the same thickness as the bottom profile 1 and the side profile 2;

[0030] The outer contour shape of the corner convex hull 3 coplanar with the bottom profile 1 or the side profile 2 is a triangle (see Picture 10 ), half waist type (see Picture 11 ) Or arc (see Picture 12 ), the convex depth of the corner convex plate on the symmetry plane of the bottom profile 1 and the side prof...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vertical height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com