Multi-flame-port longitudinal combustor for quartz fiber material processing

A technology of material processing and quartz fiber, which is applied in the field of multi-flame longitudinal burners, can solve the problems of changing the temperature of flame baking, easily blocking the flame path, and not being able to realize simultaneous cleaning of debris on multiple fire caps, to achieve The effect of expanding the baking range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

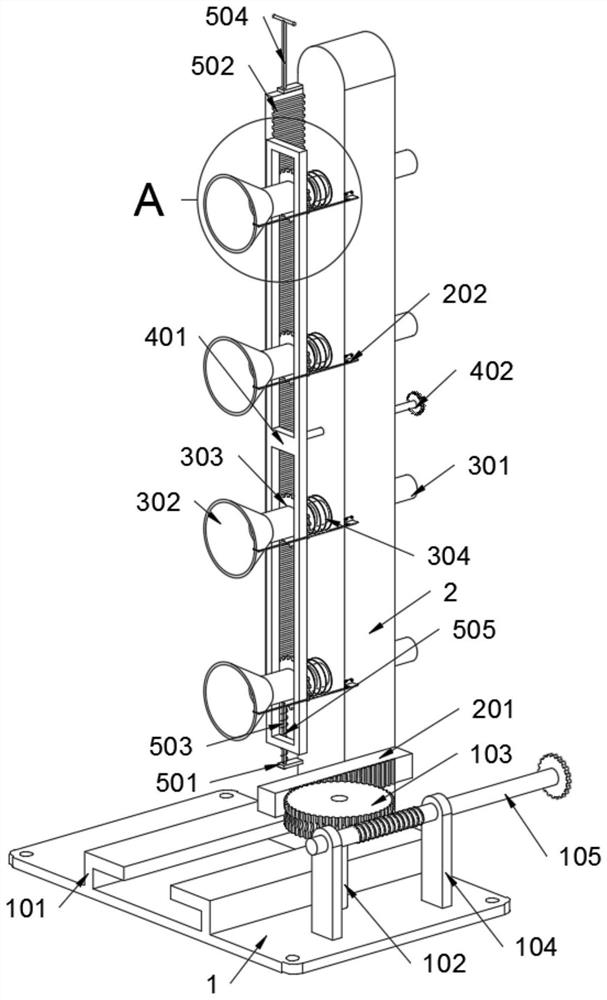

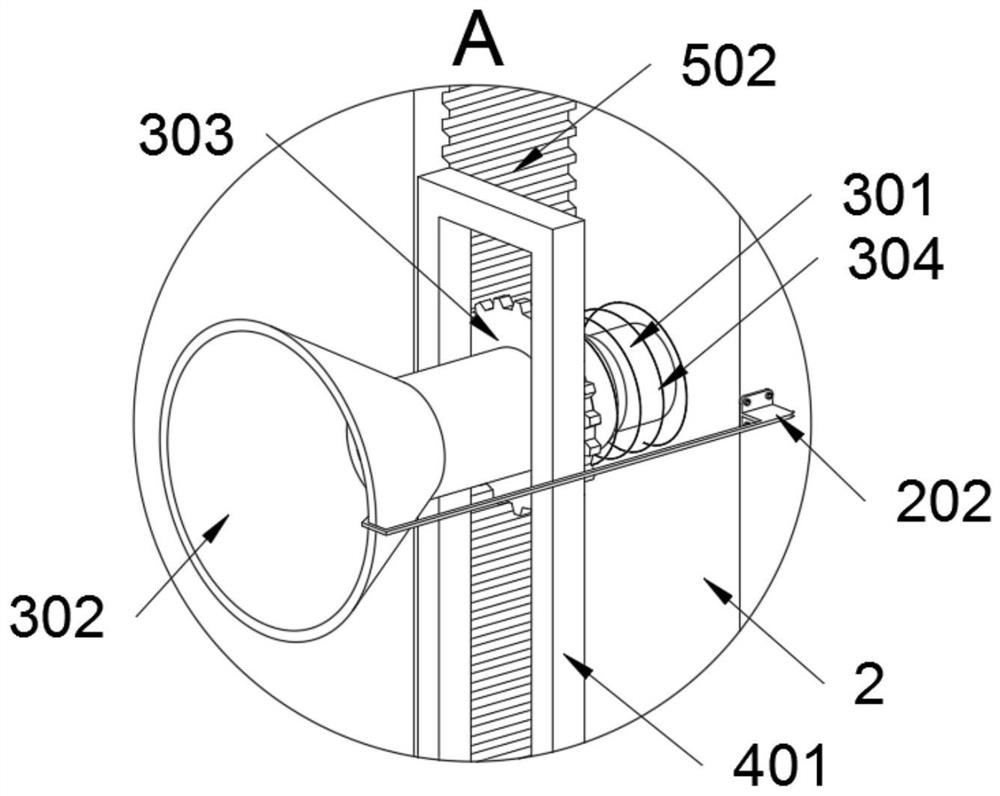

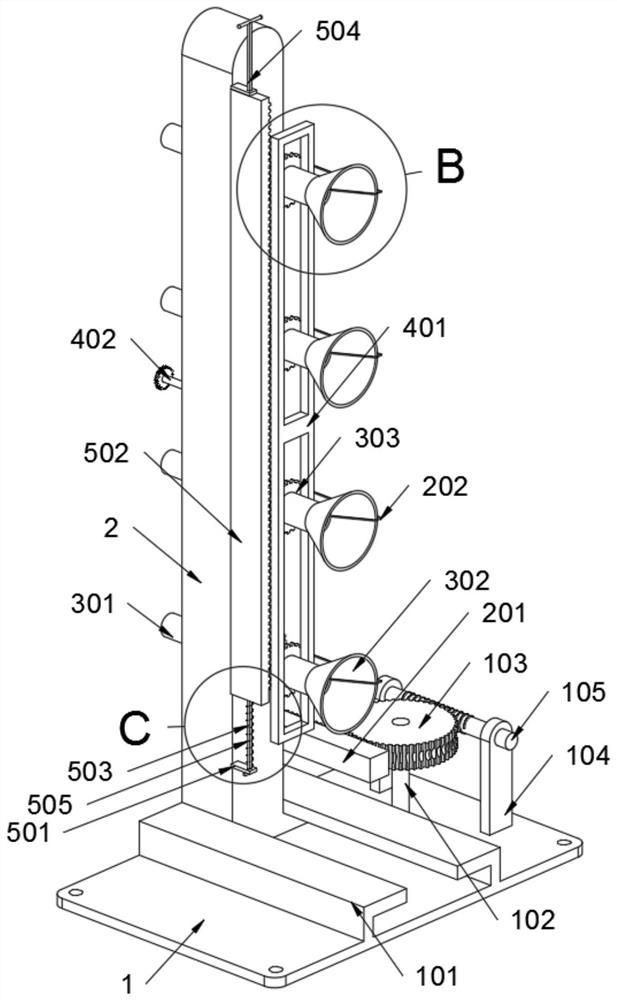

[0037] as attached figure 1 to attach Figure 9 Shown:

[0038] The invention provides a multi-flame longitudinal burner for processing quartz fiber materials, which includes a base 1; a main body rod 2 is installed on the base 1, and four nozzle structures 3 are installed on the main body rod 2 in a rectangular array; the main body rod An adjustment structure 4 is installed on the 2, and a cleaning structure 5 is also installed on the main body rod 2; refer to as image 3 and Figure 4 , the main body rod 2 includes a cleaning arm 202, and there are four cleaning arms 202 in total, and the four cleaning arms 202 are fixedly connected to the main body rod 2 in a rectangular array; the head end of the cleaning arm 202 is bent, and the cleaning arm 202 The head end is in contact with the inner wall of the fire cover 302, so that the cleaning arm 202 can clean the residue on the inner wall of the fire cover 302 when the fire cover 302 rotates.

[0039] Reference as figure 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com