Desizing-scouring-bleaching combination machine

A combined machine, descouring and bleaching technology, applied in textiles and papermaking, liquid/gas/steam textile material treatment, liquid/gas/steam removal with squeeze rollers, etc., can solve the problem of reducing the effect of fabric treatment and reducing descouring and bleaching Improve the effect of scouring and bleaching, improve the effect of deboiling and bleaching, and reduce the loss of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing 1-8, the present application is described in further detail.

[0047] The embodiment of the present application discloses a combined descouring and bleaching machine.

[0048] In this embodiment, the model of the temperature controller is TC4S / H / M / L, and the model of the PH controller is PH / ORP-2000.

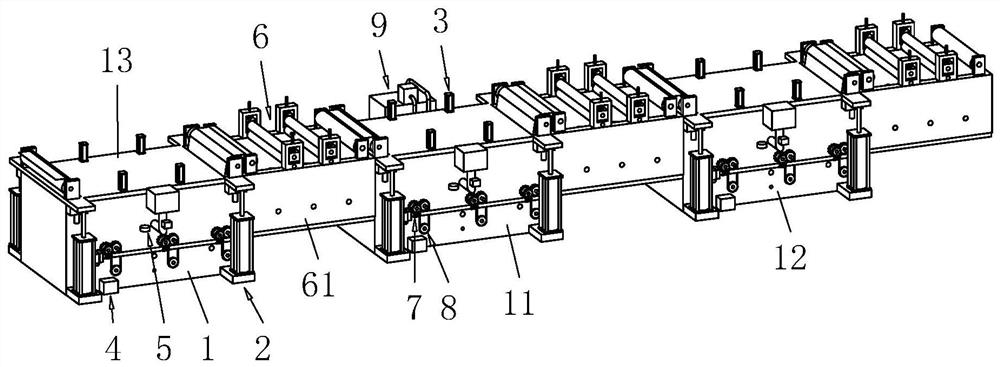

[0049] refer to figure 1 , including a desizing tank 1, a scouring tank 11 and a bleaching tank 12. The desizing tank 1, the scouring tank 11 and the bleaching tank 12 are respectively filled with reaction solutions for desizing, scouring and bleaching the cloth. The tops of the desizing tank 1, the scouring tank 11 and the bleaching tank 12 are all equipped with a cover plate 13 of the same structure, and the cover plate 13 located on the scouring tank 11 is used as an example to explain below.

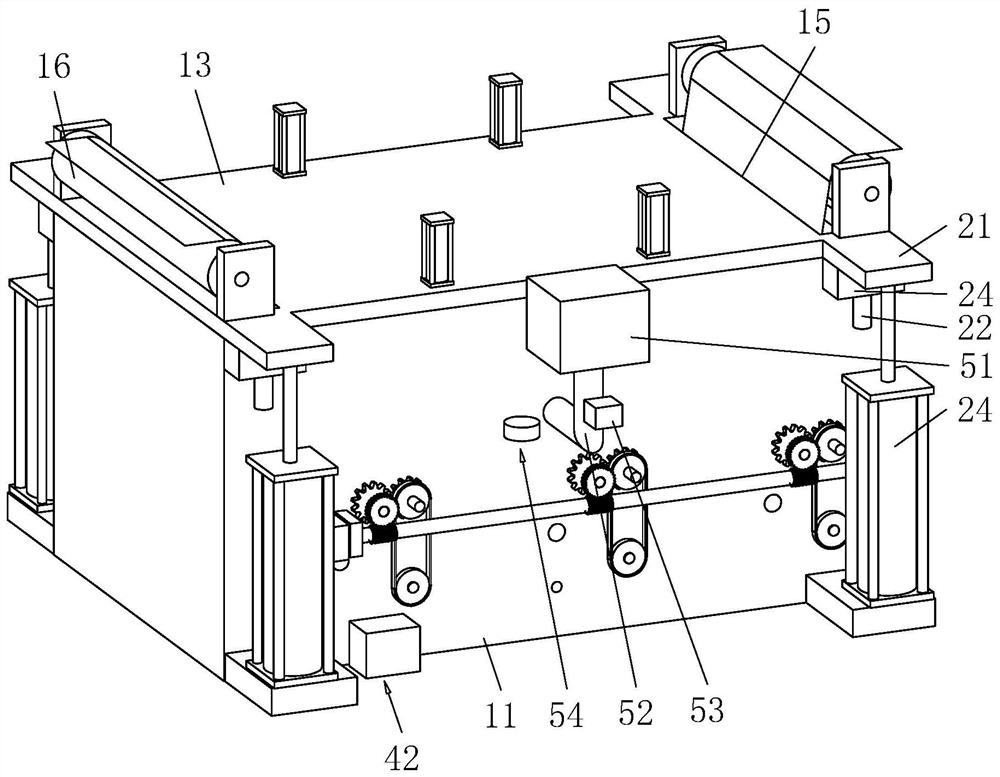

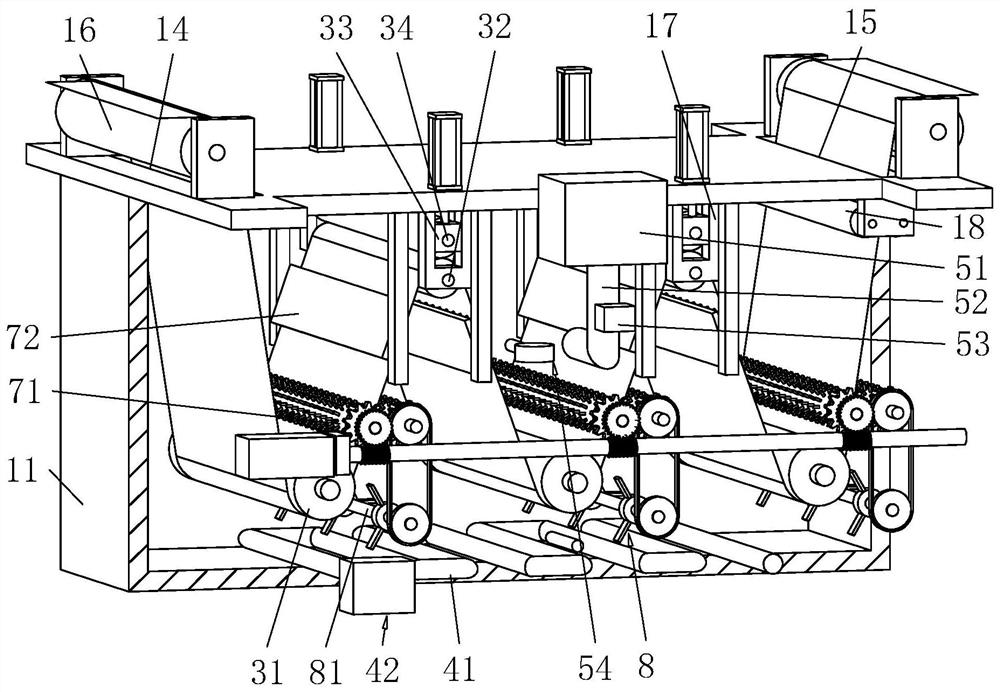

[0050] refer to figure 2 and image 3 , the cover plate 13 is provided with a cloth inlet 14 and a cloth outlet 15, and on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com