Gas-liquid linkage high-concentration slurry grouting device and method for deep water-rich goaf

A technology of gas-liquid linkage and grouting device, which is applied in safety devices, mining equipment, earth-moving drilling, etc., can solve problems such as threatening the safe production of driving face, dynamic pressure disaster, complicated process, etc., and achieve stable and continuous flow of slurry. , to achieve the effect of continuous pressure transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

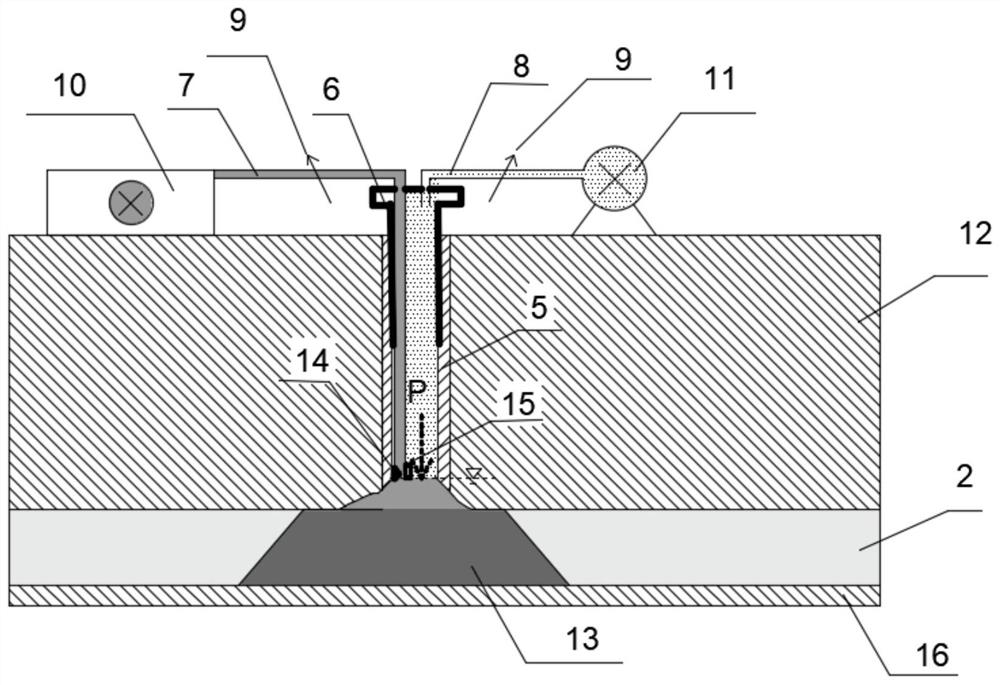

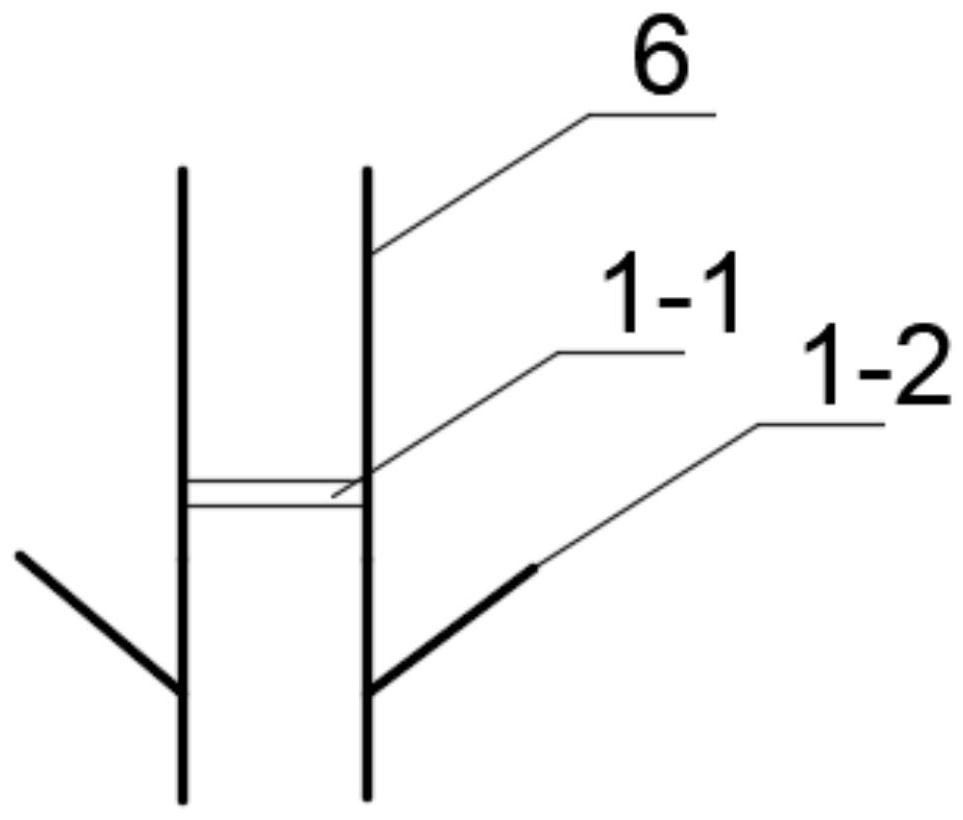

[0035] This embodiment provides a high-concentration slurry filling device for deep water-rich goafs, such as figure 2 shown. The device includes: a gas-liquid linkage grouting device 6 , a high-concentration slurry pipe 7 , an air pressure pipe 8 , a grouting pump 10 , an air pressure pump 11 , and a grouting pressure sensor 14 . The gas-liquid linkage grouting device is threaded with the orifice pipe of the grouting hole, and a high-concentration grout pipe hole and an air pressure pipe hole are arranged on the top of the device. The high-concentration grout pipe passes through the high-concentration grout pipe hole. The high-concentration grout pipe hole is welded, the ground is connected to the grouting pump, and a check valve is installed in the middle. The grouting hole is set at a position 1-2m below the designed grout level (layer), and is set at the end of the inner wall of the high-concentration grout pipe. There is a grouting pressure sensor to measure the real-ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com