On-line intelligent diagnosis and bypass protection device and control method of waste heat boiler heat pipe heat exchanger

A technology of heat pipe heat exchanger and waste heat boiler, which is applied in the direction of clean heat transfer device, steam generation method using heat carrier, combustion method, etc. ash clogging, affecting the flow of flue gas and other problems, to avoid metal damage, save energy, and ensure the effect of purging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

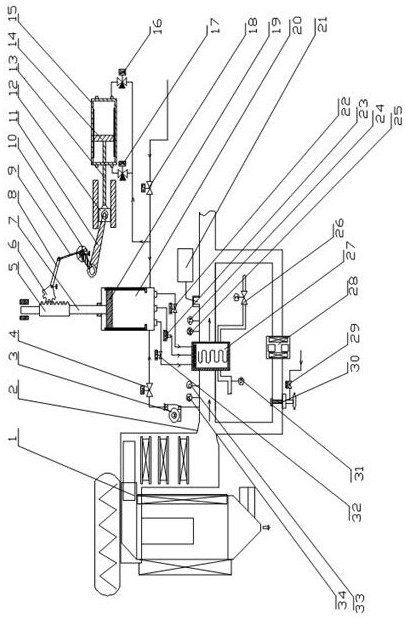

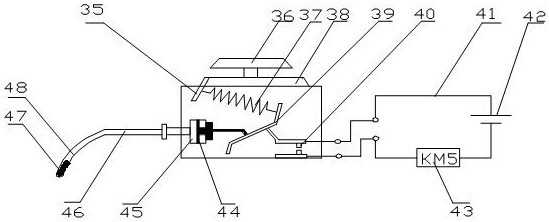

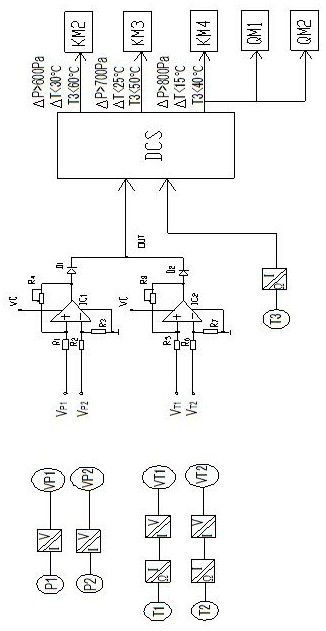

[0024] Embodiment 1: see Figure 1-Figure 3 , an online intelligent diagnosis and bypass protection device for a heat pipe heat exchanger of a waste heat boiler, the device includes: a waste heat boiler 1, a flue gas pipeline 2, a blower 3, an electric control valve 4, a lifting device, a cylinder propulsion mechanism, and a rocker arm 11 , push block 12, two-position three-way electric control valve 16, two-position three-way electric control valve 17, total gas source electric control valve 18, heavy hammer piston 19, purge gas storage tank 20, high-pressure purge electric control valve 22 , pulse purge electric control valve 23, flue gas temperature measuring point 24, flue gas pressure measuring point 25, water inlet regulating valve 26, heat pipe heat exchanger 27, heat pipe outlet water temperature measuring point 31, conventional pressure purging electric control valve 32, flue gas temperature measuring point 33 and flue gas pressure measuring point 34, the heat pipe he...

Embodiment 2

[0025] Example 2: see Figure 1-Figure 3 , the on-line intelligent diagnosis of waste heat boiler heat pipe heat exchanger and the control method of bypass protection device, it is characterized in that, described method comprises the following steps:

[0026] The first step is blockage and the vibration is not too serious. When the flue gas differential pressure ΔP is greater than 600Pa, the temperature difference ΔT is less than 30°C, and the outlet water temperature T3 is less than 60°C, the judgment logic output triggers the action of the electric control valve KM2 to perform conventional pressure purge ;

[0027] The second step is blockage, severe vibration, abnormal pressure difference between the front and back of the flue gas, water temperature and flue gas temperature, that is, when the flue gas differential pressure ΔP is greater than 700Pa, the temperature difference ΔT is less than 25°C, and the outlet water temperature T3 is less than 50°C, then the logic output ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com