Method and device for testing and evaluating shrinkage cracking performance of solidified soil materials

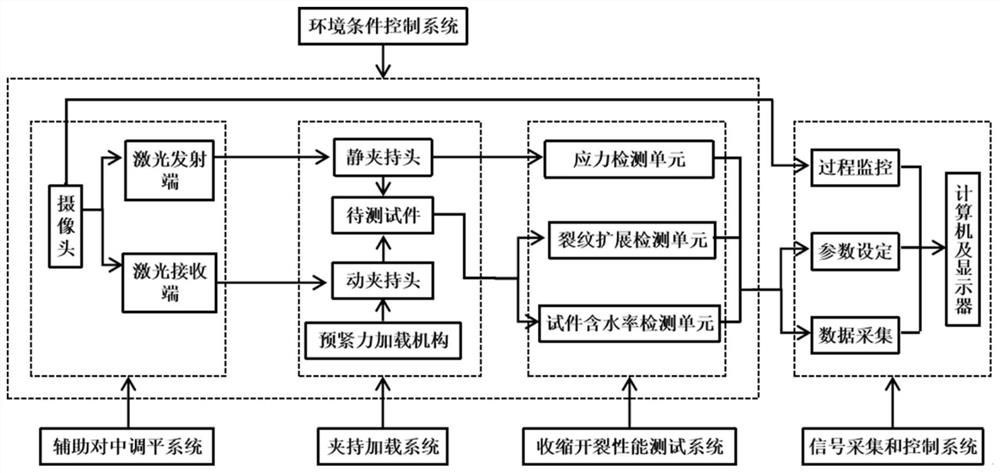

A technology of shrinkage cracking and evaluation method, which is applied in measurement devices, material analysis, and material analysis by optical means. , the effect of high-precision testing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

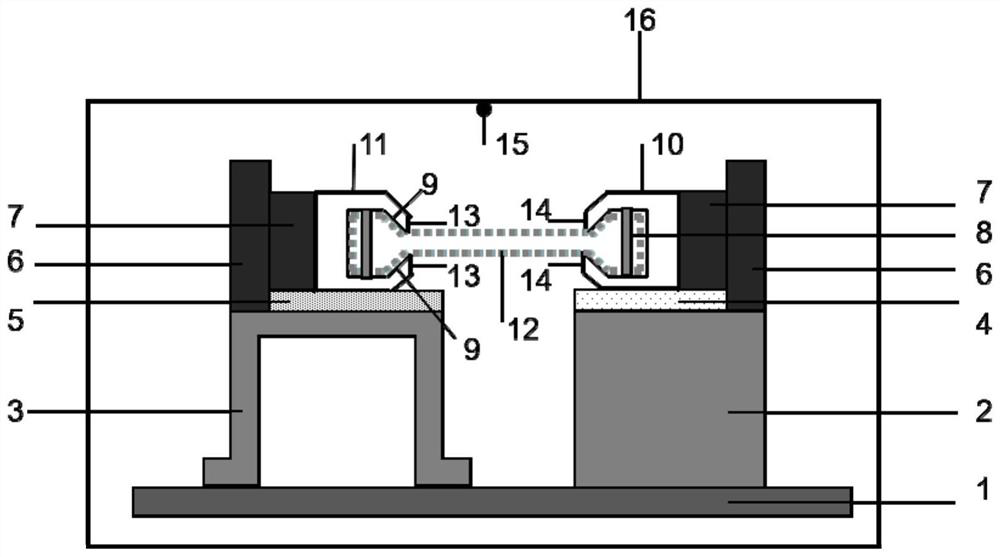

Examples

Embodiment 1

[0071] Drying shrinkage test of lime soil: the soil source selected in this embodiment is soft soil obtained from subway excavation, the lime content is 5%, and the compaction degree is controlled at 95%. The specimens were made by static pressure forming method under the condition of optimum moisture content of 18%. The specific test steps are as follows:

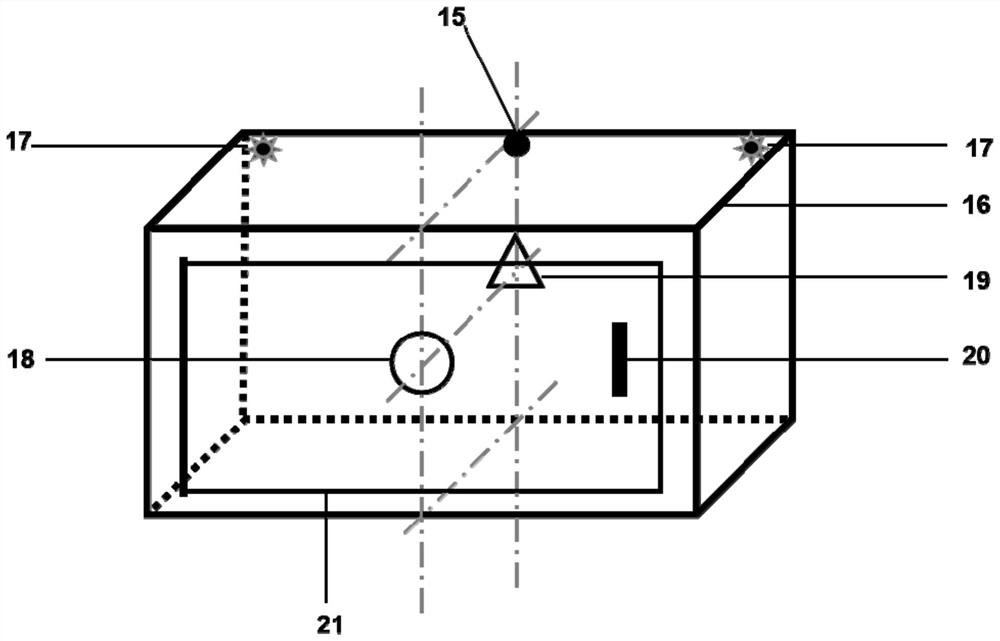

[0072] (1) Test piece making: adopt customized mould, make test piece size and attached in the present invention Figure 4 Consistent, in the shape of a dog bone. First, mix the soft soil that has been dried through a 4.75cm sieve with lime and water evenly, then weigh a certain amount of solidified soil and put it into the test mold, use a universal press to form it statically, and remove the mold after 24 hours. , and bagged and put into a standard curing room for curing, the curing time is 7 days.

[0073] (2) Start-up of the test chamber: open the test chamber and preheat it, adjust the temperature to 25°C, and the ...

Embodiment 2

[0085] Lime soil temperature shrinkage test: The soil source selected in this example is clay obtained from subway excavation, the cement content is 7%, and the compaction degree is controlled at 95%. The specimens were made by static pressure forming method under the condition of optimal moisture content of 16%. The specific test steps are as follows:

[0086] (1) Test piece making: adopt customized mould, make test piece size and attached in the present invention Figure 4 Consistent, in the shape of a dog bone. First, mix the clay that has been dried through a 4.75cm sieve with cement and water evenly, then weigh a certain amount of solidified soil and put it into the test mold, use a universal press to form it statically, and remove the mold two hours after forming. Bagged and placed in a standard curing room for curing, the curing time is 7 days, and placed in an oven on the last day, the temperature of the oven is set at 105°C for drying, and finally reaches a dry stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com