Production technology of forsythia suspensa leaf tea

A preparation process and technology for forsythia, applied in the field of preparation technology of forsythia tea, can solve the problems of bitter taste of forsythia tea, unsuitable for promotion, etc., and achieve the effects of protecting aroma and taste, improving color and taste, and improving tea quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

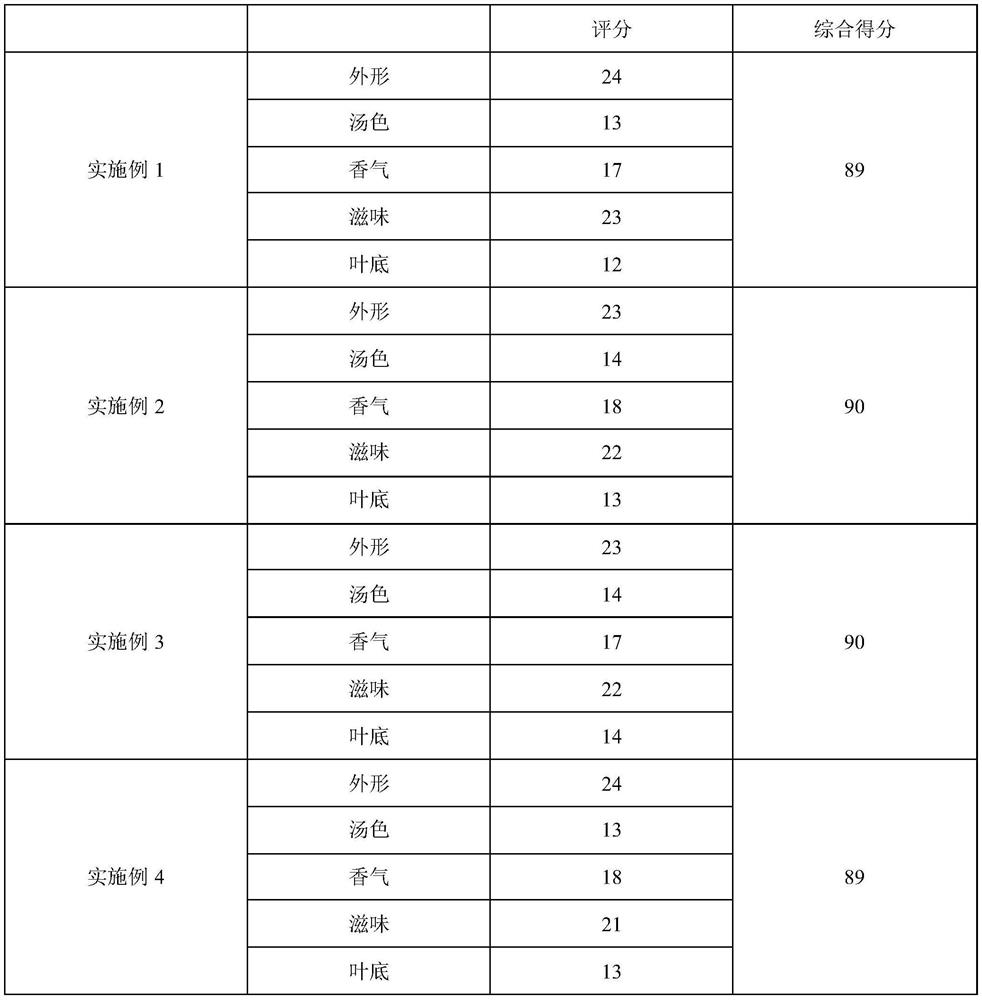

Examples

Embodiment 1

[0022] A preparation process for forsythia tea, comprising the following steps:

[0023] Step 1, select forsythia leaves 4-5 days after flowering and not fully stretched for picking. Choose forsythia leaves 4 to 5 days after flowering as raw materials. At this time, the leaves are soft and tender, suitable for making forsythia tea, and the forsythia tea made from older forsythia leaves has poor drinking taste.

[0024] Step 2: Clean the picked forsythia leaves and spread them in the sun until they are half-dried.

[0025] Step 3, put the forsythia leaves after spreading in the sun in the steamer, wait for the water in the drawer to boil before adding the forsythia leaves, the steaming time is 3-5min, the steaming time should not be too long, Too long will destroy the effective components of the forsythia leaves, and is not conducive to subsequent processing. The forsythia leaves are taken out and spread flat to cool, and the steaming-cooling process is repeated three times f...

Embodiment 2

[0029] A preparation process for forsythia tea, comprising the following steps:

[0030] Step 1, select forsythia leaves 4-5 days after flowering and not fully stretched for picking. Choose forsythia leaves 4 to 5 days after flowering as raw materials. At this time, the leaves are soft and tender, suitable for making forsythia tea, and the forsythia tea made from older forsythia leaves has poor drinking taste.

[0031] Step 2: Clean the picked forsythia leaves and spread them in the sun until they are half-dried.

[0032] Step 3, put the forsythia leaves after spreading in the sun in the steamer, wait for the water in the drawer to boil before adding the forsythia leaves, the steaming time is 3-5min, the steaming time should not be too long, Too long will destroy the effective components of the forsythia leaves, and is not conducive to subsequent processing. The forsythia leaves are taken out and spread flat to cool, and the steaming-cooling process is repeated three times f...

Embodiment 3

[0036] A preparation process for forsythia tea, comprising the following steps:

[0037] Step 1, select forsythia leaves 4-5 days after flowering and not fully stretched for picking. Choose forsythia leaves 4 to 5 days after flowering as raw materials. At this time, the leaves are soft and tender, suitable for making forsythia tea, and the forsythia tea made from older forsythia leaves has poor drinking taste.

[0038] Step 2: Clean the picked forsythia leaves and spread them in the sun until they are half-dried.

[0039] Step 3, put the forsythia leaves after spreading in the sun in the steamer, wait for the water in the drawer to boil before adding the forsythia leaves, the steaming time is 3-5min, the steaming time should not be too long, Too long will destroy the effective components of the forsythia leaves, and is not conducive to subsequent processing. The forsythia leaves are taken out and spread flat to cool, and the steaming-cooling process is repeated three times f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com