Detachable handle structure of water machine

A handle and water machine technology, applied in the installation of handles, electrical equipment, cleaning equipment, etc., can solve the problems of increasing the difficulty of operation, increasing labor intensity, not having electronic control devices, etc., reducing labor intensity, simplifying operation, and safety. Reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the drawings and specific embodiments.

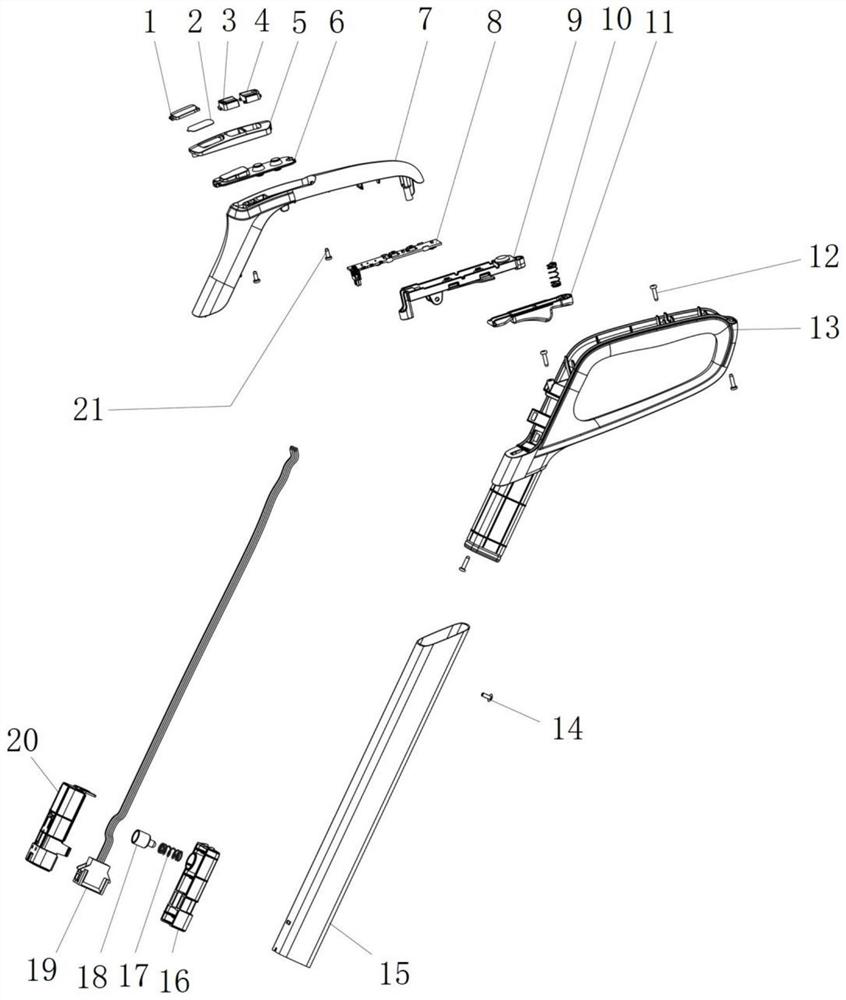

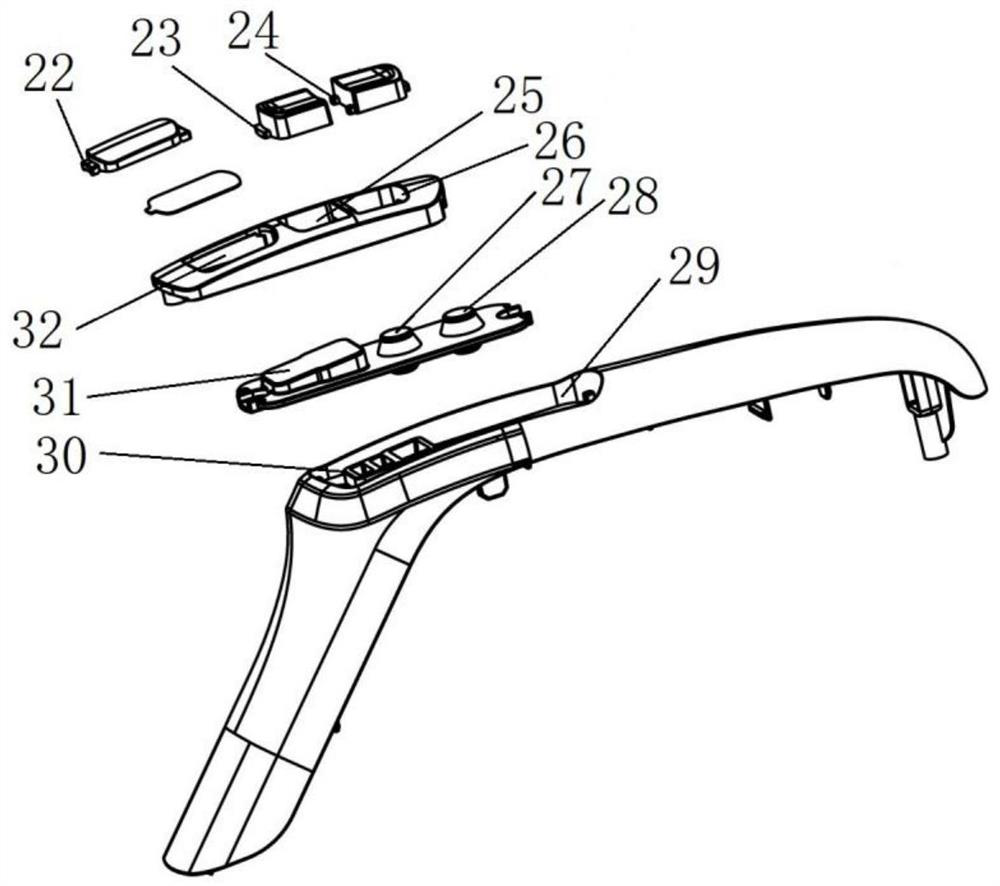

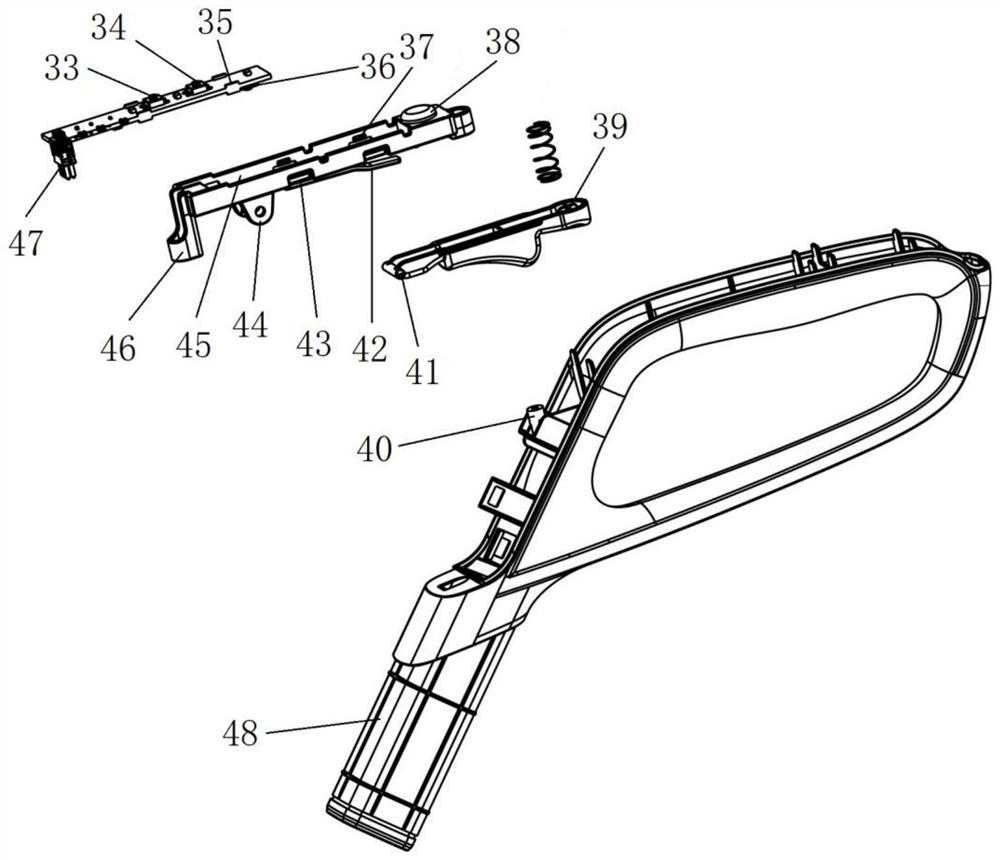

[0024] Such as figure 1 In the described embodiment, a detachable handle structure for a water machine includes a handle body 13, a handle upper cover 7, a button assembly, a circuit board assembly and a square tube assembly. The circuit board assembly is installed on the handle body 13 and placed on the handle. Between the body 13 and the upper handle cover 7, the button assembly is installed on the upper handle cover 7 and connected to the circuit board assembly. The square tube assembly includes a square tube body 15 and a plug assembly. The plug assembly is installed at the lower end of the square tube body 15. The upper end of the pipe body 15 is mounted on the handle body 13, and the plug assembly is electrically connected with the circuit board assembly. The lower end of the handle body 13 is provided with a plug 48, and the square tube body 15 is inser...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap