Flow guide structure and absorption product

A technology of absorbent products and diversion layer, which is applied in the field of sanitary products, can solve the problems of easy leakage and insufficient dryness of the diversion structure, and achieve the effect of ensuring dryness and increasing the absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

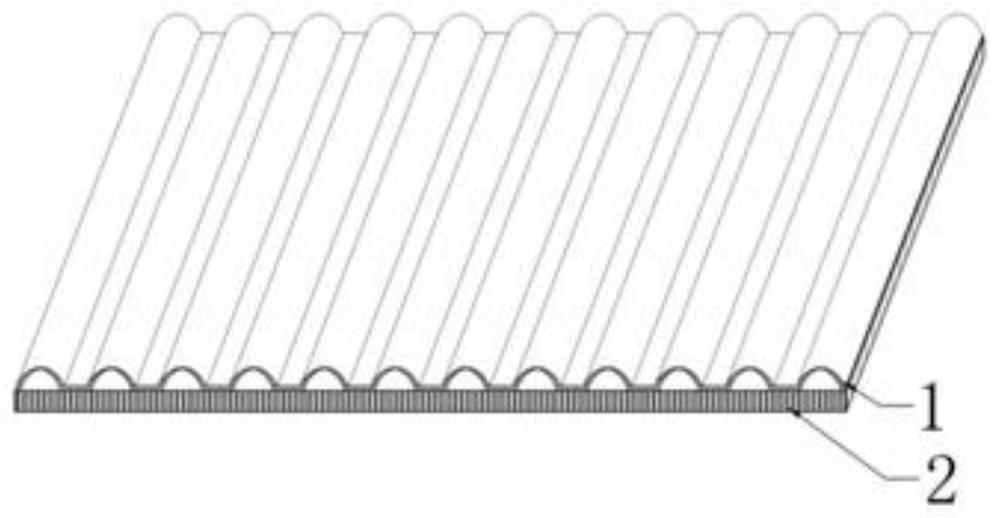

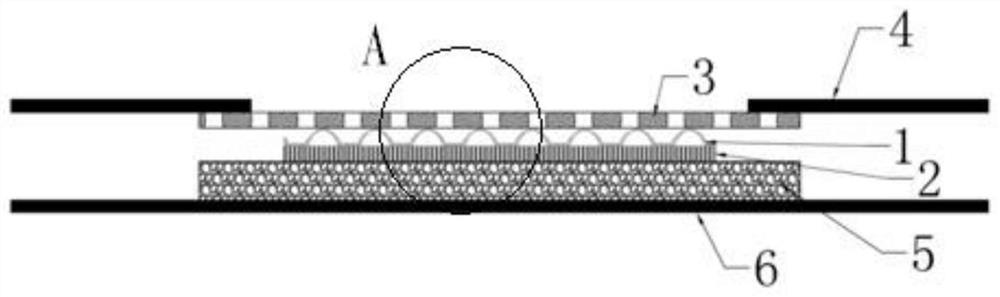

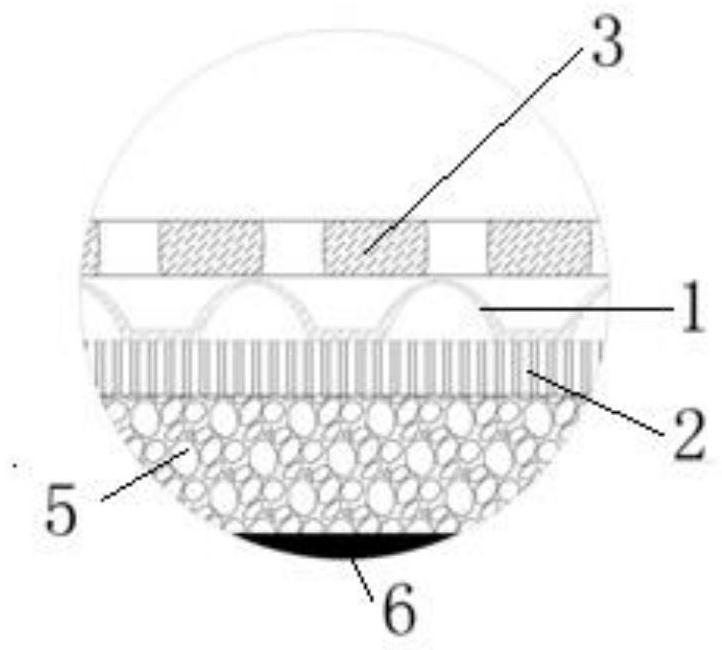

[0042] see Figure 1-Figure 3 , in the flow guide structure provided by this embodiment, the depressions and projections in the first flow guide layer 1 are elongated structures respectively, and the depressions and projections are parallel to each other; the depressions and projections are respectively multiple , the two are arranged crosswise.

[0043] The section of the protruding part along the direction perpendicular to its extending direction is arc-shaped, and the protruding part protrudes toward the surface layer 3; the concave part is flat. In this embodiment, the channel-shaped liquid temporary storage area is formed by cooperating with the surface layer at the recessed part.

[0044] In this solution, the surface layer 3 is made of perforated non-woven fabric, and the second flow guide layer 2 is made of plain non-woven fabric.

[0045] In application, the liquid is absorbed by the surface layer 3 and reaches the flow guide layer, wherein the first flow guide laye...

Embodiment 2

[0047] see Figure 4-Figure 6, in the diversion structure provided by this embodiment, there is one raised part, which is in the shape of a flat plate; there are multiple depressed parts, which are dispersedly arranged on the raised part; the inner wall section of the depressed part is arc-shaped, and the inner wall of the depressed part The wall surface is spherical or similar to a spherical surface; the depression gradually moves away from the surface layer 3 from its opening to the maximum depth.

[0048] In the diversion structure provided in this embodiment, the surface layer 3 includes a plurality of arc-shaped parts parallel to each other, and each arc-shaped part is arranged in sequence along the first direction and connected as a whole; the above-mentioned first direction is the busbar with the arc-shaped parts vertical. The surface layer 3 is perforated and formed by 3D pressing. Specifically, the first flow guiding layer 1 is a non-woven fabric layer with circular...

Embodiment 3

[0051] see Figure 7-Figure 9 , in the diversion structure provided by this embodiment, the raised portion is a circular raised portion, which protrudes toward the surface layer 3, and there are multiple raised portions distributed on the depressed portion in multiple rows, and the raised portion can specifically be distributed in a matrix. The number of depressions is one.

[0052] The surface layer 3 is a perforated non-woven fabric layer. During application, the liquid is absorbed by the surface layer 3 and reaches the raised part. The raised part quickly conducts the liquid downward. At the same time, the raised part has a small liquid holding capacity due to the low density of the material. Moreover, the second flow guide layer 2 is separated from the raised portion and the core body 5 , so the raised portion can well reduce liquid reverse seepage and further improve the dryness of the flow guide structure.

[0053] In the flow guide structure provided by the above embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com