The pressure stabilization method of the bag filter

A technology of bag dust collector and voltage stabilization, which is applied to chemical instruments and methods, separation methods, and separation of dispersed particles, etc. It can solve the problems of negative pressure fluctuations in the front-end process, achieve good production quality and reduce pressure fluctuations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The method for stabilizing the pressure of the bag filter in this embodiment is to add gas to the bag filter or the main pipeline connected to the front end of the bag filter before each pulse cleaning starts, and the process of adding gas lasts for a period of time. The molar amount V of the supplementary gas 1 and the gas molar amount V of this pulse cleaning 2 between V 1 = 95%V 2 ~105%V 2 .

[0052] The pressure P of the supplementary gas 0 The pressure P in the main pipeline connected to the bag filter or the bag filter and the front end 1 Meet 0.95P 1 0 1 , the pressure P of the supplementary gas 0 1.02P can be selected 1 , 1.03P 1 , 1.04P 1 ,P 1 , 0.99P 1 , 0.98P 1 or 0.96P 1 . The supplementary gas output from a higher pressure gas source can be adjusted to meet the pressure requirements, thus reducing the pressure fluctuation at the front end.

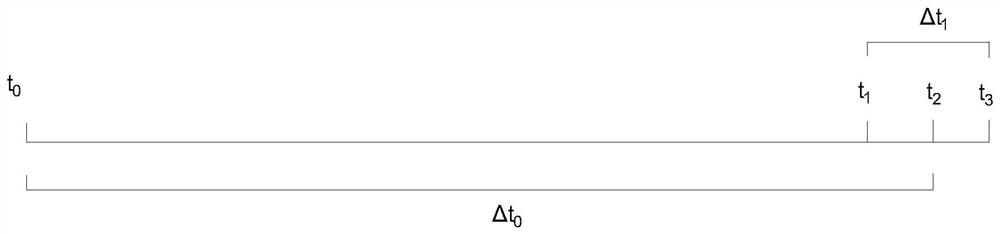

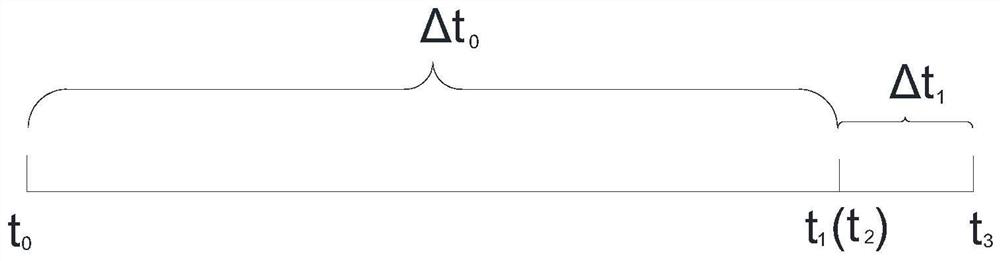

[0053] The opening time of the pulse cleaning is t 1 , the pulse cleaning duration is Δt 1 , then t...

Embodiment 2

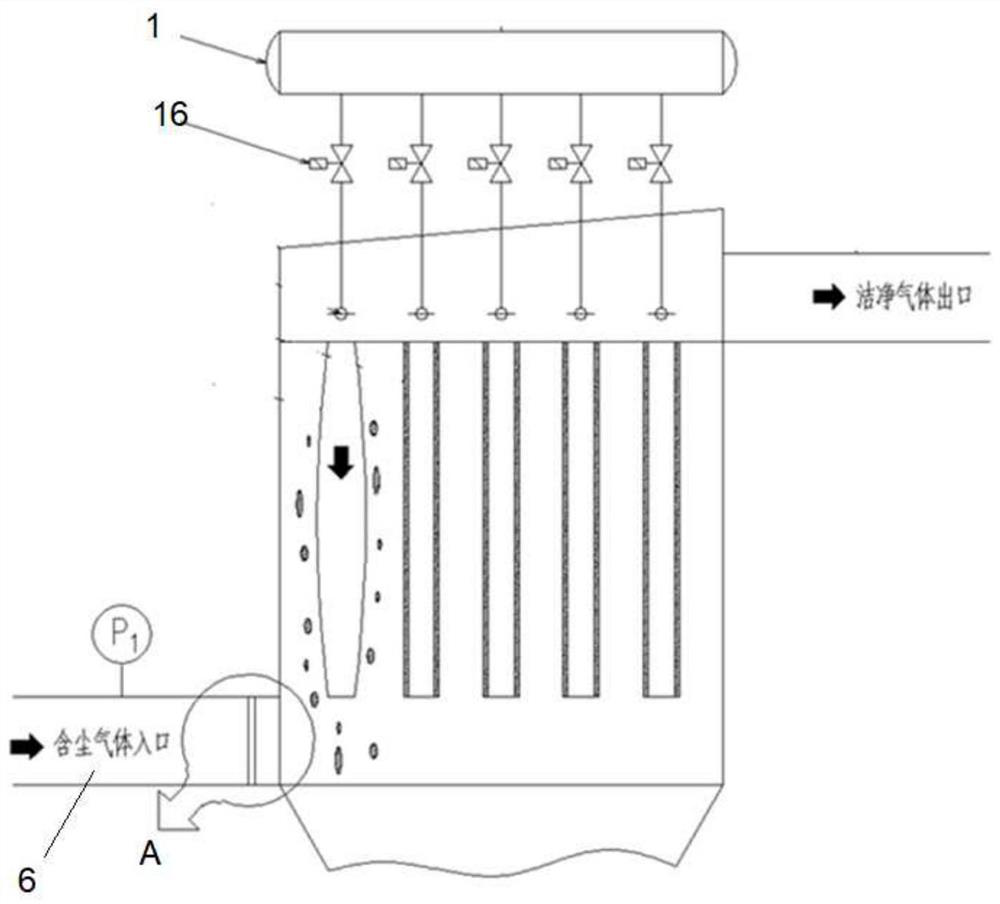

[0058] Such as Figure 4 As shown, the pressure stabilizing device of the bag filter in this embodiment includes: a gas source, which is used to provide supplementary gas; an adjustment mechanism, the adjustment mechanism is respectively set in communication with the gas source and the target position, and the gas source, the adjustment mechanism and the target position Form a communicable gas path. The target location is the bag filter or the main pipe 6 where the bag filter is connected to the front end. In this embodiment, the target location is the main pipeline 6 connected to the front end of the bag filter.

[0059] This embodiment also includes a general controller 7, which controls the opening and closing of the regulating mechanism, and the general controller 7 monitors the pressure fluctuation of the main pipeline 6 connected to the front end of the bag filter. In this embodiment, the general controller 7 uses PLC. The gas source described in this embodiment is th...

Embodiment 3

[0074] Such as Figure 11 As shown, the pressure stabilizing device of the bag filter in this embodiment includes: a gas source, which is used to provide supplementary gas; an adjustment mechanism, the adjustment mechanism is respectively set in communication with the gas source and the target position, and the gas source, the adjustment mechanism and the target position Form a communicable gas path. The target location is the bag filter or the main pipe 6 where the bag filter is connected to the front end. In this embodiment, the target location is the main pipeline 6 connected to the front end of the bag filter. The gas source in this embodiment is an independent gas source 20 independent of the gas bag 1 . This embodiment also includes a general controller 7, which controls the opening and closing of the regulating mechanism, and the general controller 7 monitors the pressure fluctuation of the main pipeline 6 connected to the front end of the bag filter. In this embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com