Industrial waste gas treatment device

A technology for treatment devices and industrial waste gas, which is applied in the directions of dispersed particle separation, direct contact heat exchangers, chemical instruments and methods, etc. Air pollution, the effect of reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

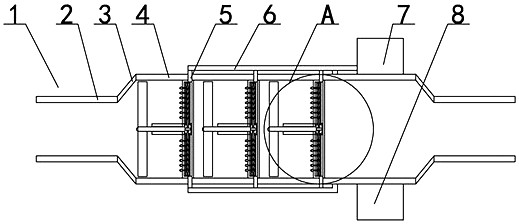

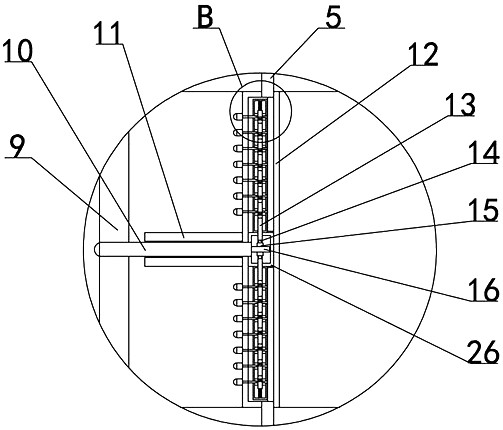

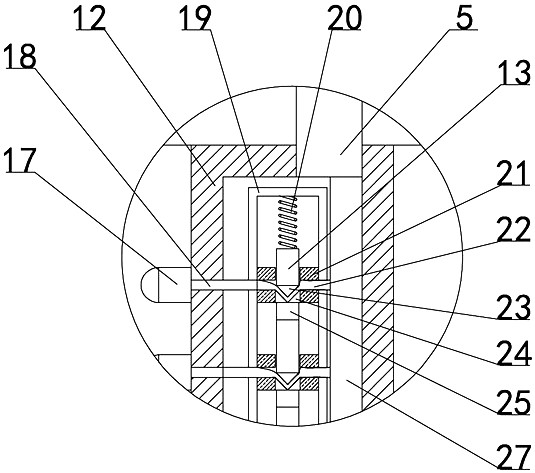

[0021] like Figure 1-6 As shown, an industrial waste gas treatment device includes a device body 1, the left side of the device body 1 is connected to the intake pipe 2, the right side of the intake pipe 2 is connected to the expansion pipe 3, the right side of the expansion pipe 3 is connected to the processing cylinder 4, and the upper side of the processing cylinder 4 The water tank 7 is fixed, the waste water tank 8 is fixed on the lower side of the treatment cylinder 4, three sets of blades 9 are arranged in the treatment cylinder 4, the middle part of each set of blades 9 is fixed on the first rotating shaft 10, and the right part of the first rotating shaft 10 is rotated and arranged in the casing 11 , the s...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap