Micro-positive pressure vacuum pressure swing adsorption system and method for safely enriching low-concentration gas

A vacuum pressure swing adsorption and low-concentration gas technology, which is applied in separation methods, gas discharge, safety devices, etc., can solve problems such as shortening the service life of adsorbents, increasing gas separation costs, and increasing process complexity, etc., to reduce gas explosions risk, improvement of gas treatment efficiency, and improvement of methane separation and concentration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

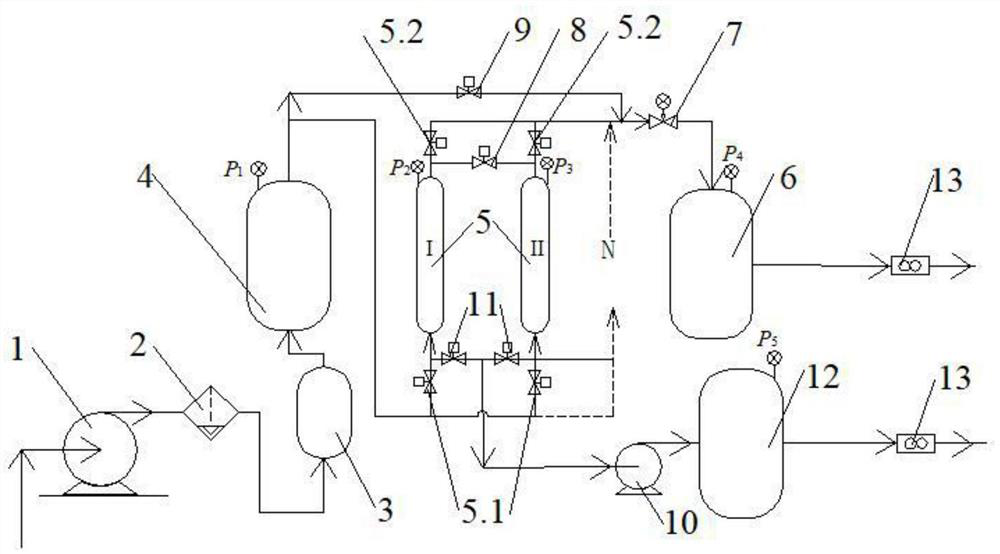

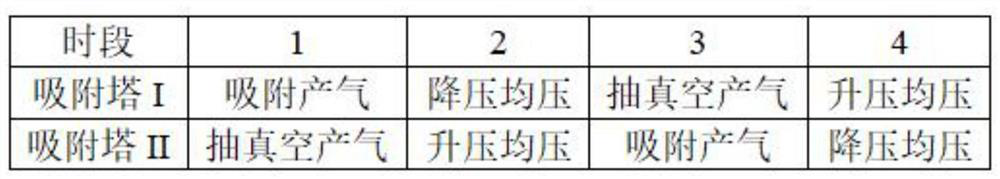

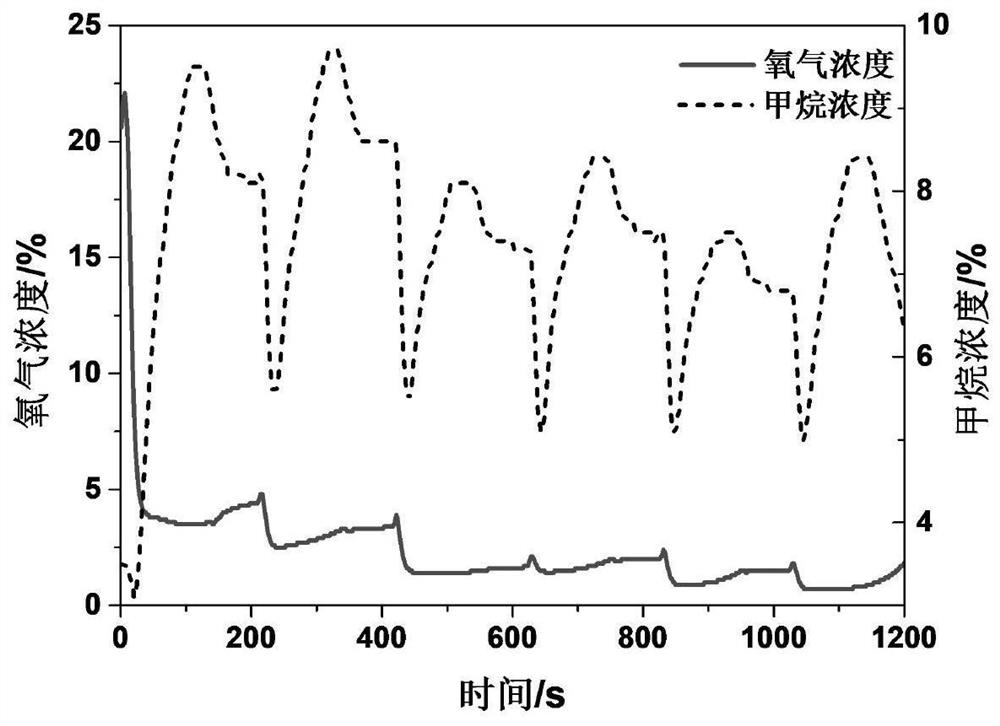

[0051] In order to illustrate the technical effect of the present invention, present embodiment 1 selects the low-concentration gas of methane concentration 3.5%, oxygen concentration 19%, nitrogen concentration 77.5% as raw material gas, and the slight positive pressure of gas extraction water ring vacuum pump 1 output is 20kPa, The vacuum of adsorption tower 5 is 80kPa, the ratio of height and diameter of adsorption tower 5 is 12:1, the volume ratio of intake buffer tank 4 and adsorption tower 5 is 8:1, and the adsorbent is CMS-260. The pressure of the pressure valve 7 is 1kPa, and the adsorption time is 120s. The explosion-proof and anti-static materials are filled in the adsorption tower from the bottom up to 2 / 3 of the tower height. The volume ratio of the explosion-proof and anti-static materials to the adsorbent in the filling area is 6%. The above separation steps of the present invention carry out the separation and concentration of low-concentration gas, and the metha...

Embodiment 2

[0053] In this embodiment, low-concentration gas with a methane concentration of 4.5%, an oxygen concentration of 19%, and a nitrogen concentration of 76.5% is selected as the raw material gas. The micro positive pressure output by the water ring vacuum pump 1 for gas extraction is 20kPa, and the vacuum degree of the adsorption tower is 80kPa. , the height and diameter ratio of the adsorption tower 5 is 24:1, the volume ratio of the intake buffer tank 4 and the adsorption tower 5 is 8:1, the pressure of the gas production back pressure valve 7 is 1kPa, and the adsorbents are made of different types. Nitrogen-carbon molecular sieves CMS-3KT, CMS-F, CMS-260, CMS-240, CMS-220 and CMS-180 are filled with explosion-proof and anti-static materials from the bottom up to 2 / 3 of the tower height inside the adsorption tower, and the filling The volume ratio of the anti-explosion and anti-static materials to the adsorbent in the area is 6%, and the steps shown in the above embodiment are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com