Universal alloy saw blade top grinding and surface grinding machine

A general-purpose, surface grinding machine technology, applied in metal sawing equipment, metal processing equipment, tool manufacturing of sawing machines, etc., to achieve the effects of large transmission ratio, high grinding accuracy and high tooth changing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

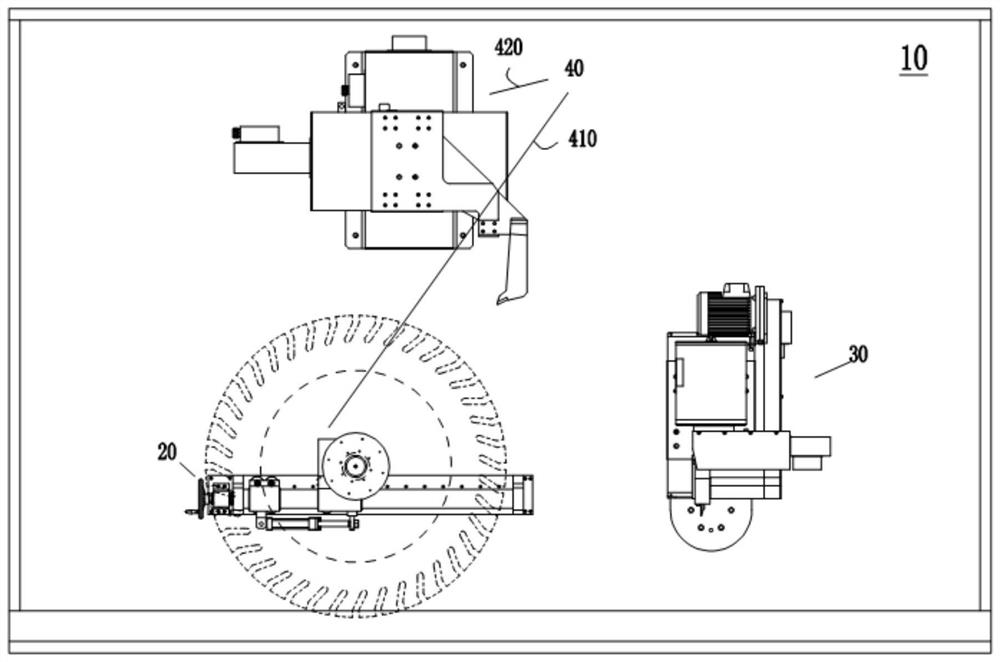

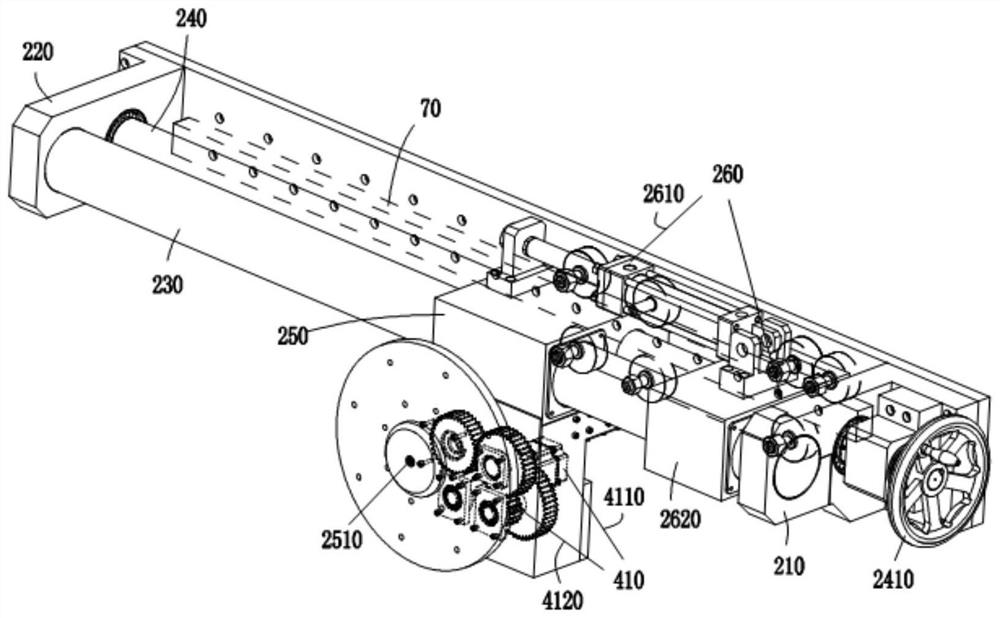

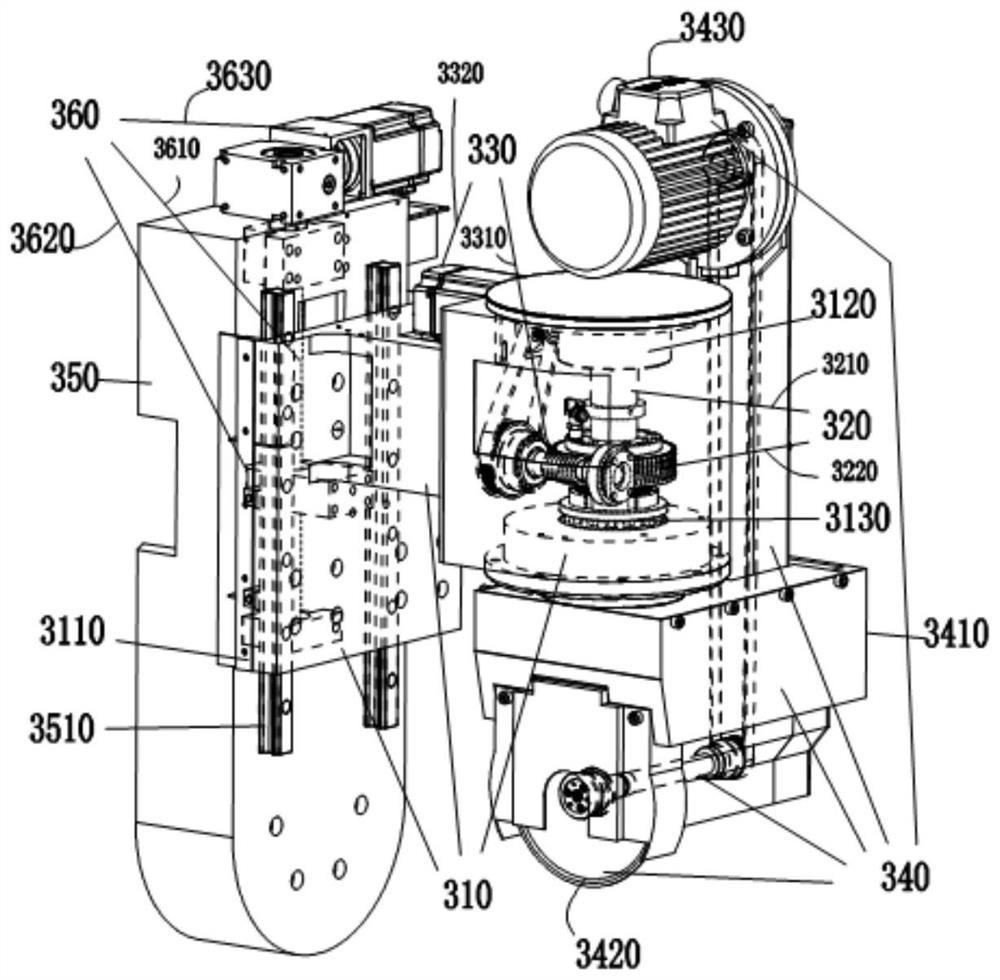

[0049] see Figure 1-Figure 4 , the general-purpose alloy saw blade top grinding and surface grinding machine provided by the application includes a machine frame 10, a hanging plate mechanism 20, a grinding head assembly 30 and a gear shifting mechanism 40. The machine frame 10 is used to carry the hanging plate mechanism 20, the grinding head assembly 30 and the shifting gear mechanism 40, the hanging plate mechanism 20 is used to hang the carbide saw blade to be ground, and the grinding head assembly 30 is used to provide the saw blade grinding function , The shifting gear mechanism 40 is used to complete the automatic gear changing operation of the saw blade.

[0050] see figure 1 and figure 2 , The hanging plate mechanism 20 includes a front axle seat 210 , a rear axle seat 220 , a track axle 230 , an adjustment axle 240 , a hanging plate seat 250 and a limiting mechanism 260 .

[0051] The track shaft 230 and the adjustment shaft 240 are arranged in parallel between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com