Electric wheel system integrating shock absorption and power generation, working method thereof, and vehicle

A technology of electric wheels and shock absorbers, which is applied to vehicle components, electric power devices, springs/shock absorbers, etc., can solve the problems of reduced motor reliability, increased wheel mass, and increased wheel system mass, achieving a large reduction The damage of current shock, the effect of reducing drag torque, improving handling and comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

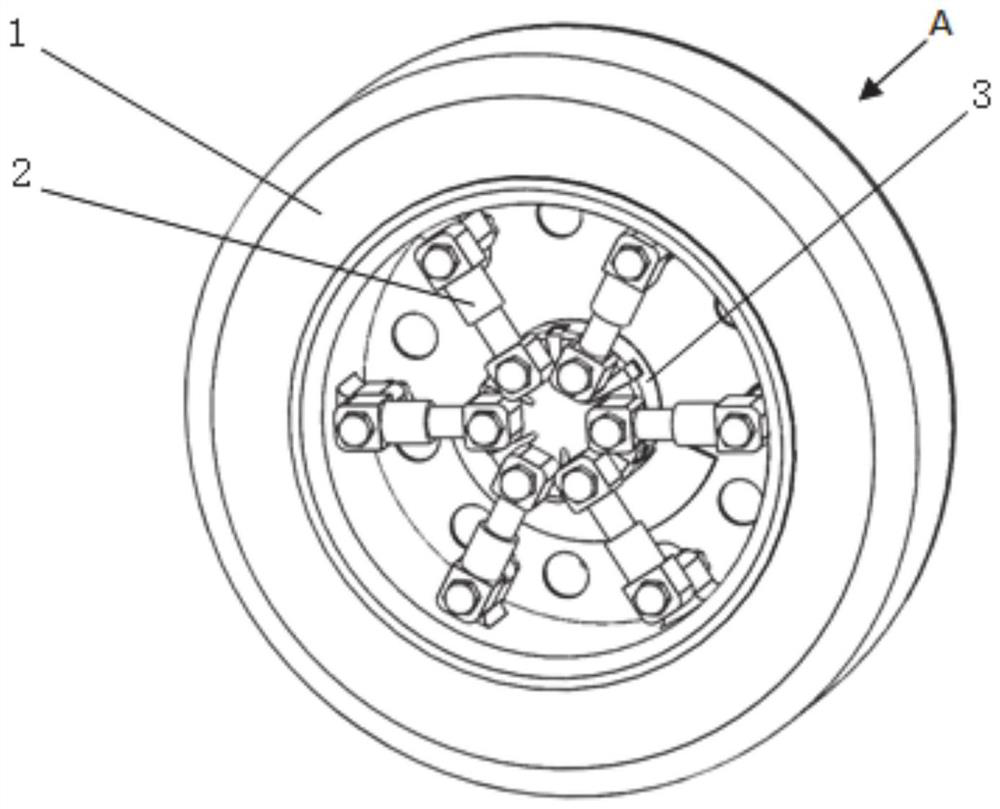

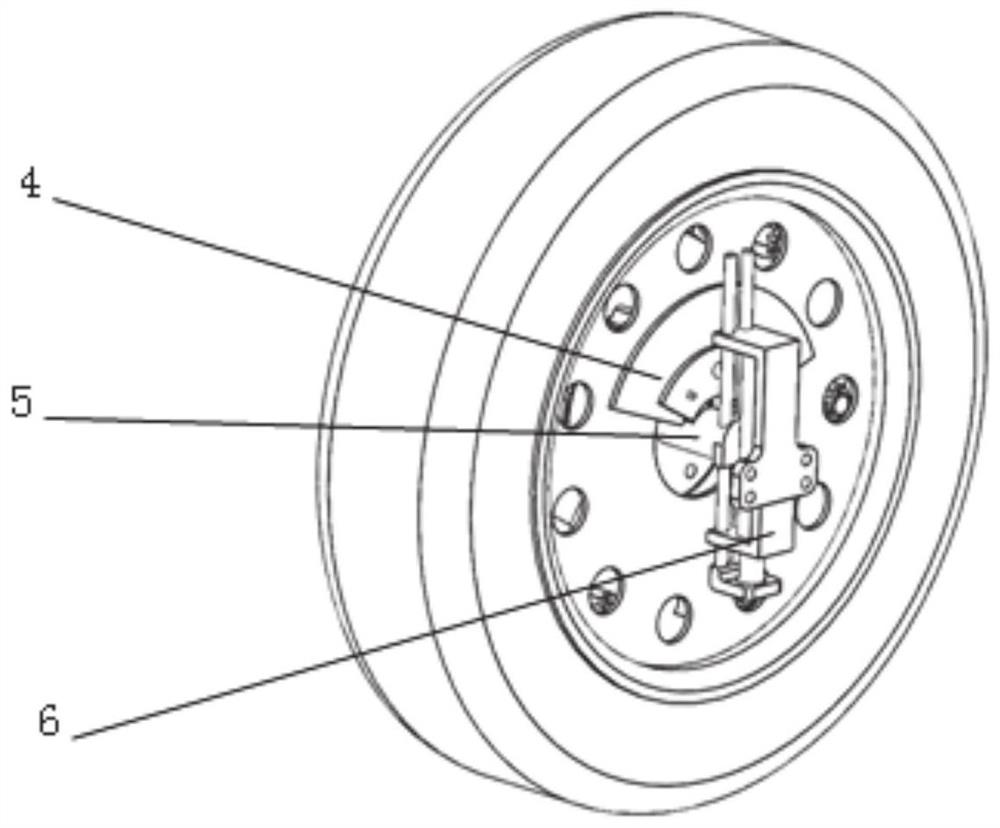

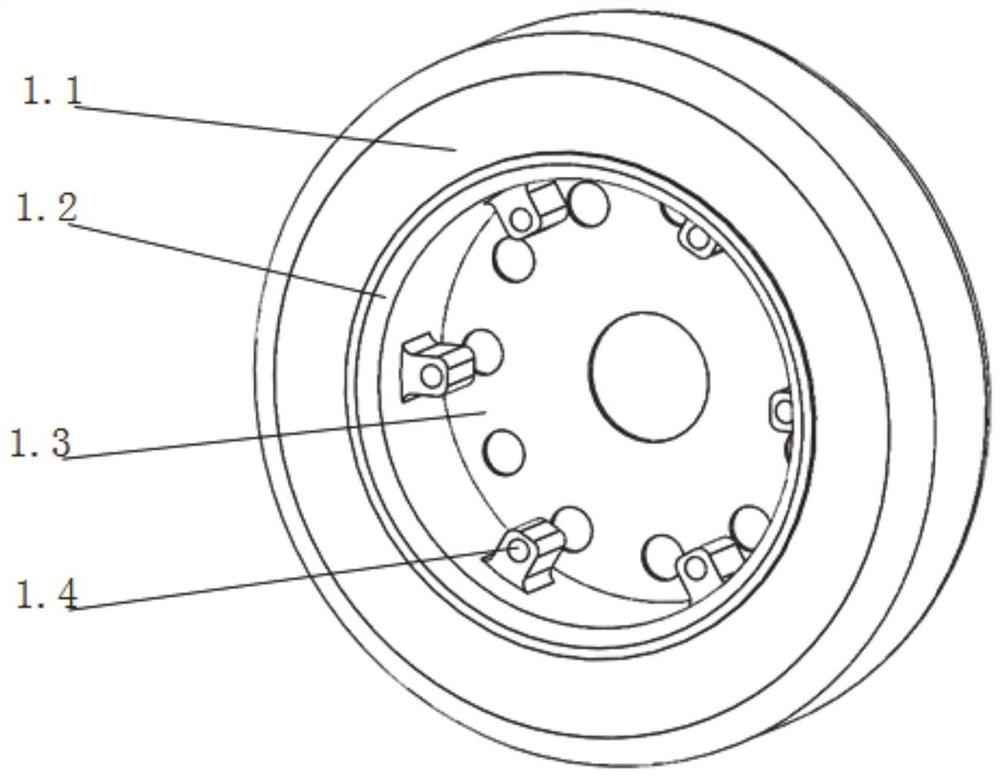

[0045] In the technical solutions disclosed in one or more embodiments, such as Figure 1-19 As shown, an electric wheel system integrating shock absorption and power generation includes a wheel 1, a drive motor 3, a wheel shock absorber 2 and a main shock absorber 6, and the main shock absorber 6 is fixedly connected to the drive motor 3 through an axle 5 The fixed part of the axle 5 realizes the fixation and support of the drive motor 3; the rotating part of the drive motor 3 is connected with the wheel steel ring 1.2 of the wheel through the wheel shock absorber 2, and is used to pass the driving force of the drive motor 3 through The wheel shock absorber 2 is transmitted to the wheel to realize the driving of the wheel.

[0046] In this embodiment, the rotating part of the driving motor 3 is the power output part, which is connected with the rotor of the motor, and the stationary part of the driving motor 3 is the stator part, so as to realize the stable support of the mot...

Embodiment 2

[0080] The present embodiment also provides the working method based on the above-mentioned wheel system, as follows:

[0081] The driving method is as follows: the drive motor 3 is powered on, the shell of the drive motor 3 drives the wheel shock absorber 2 to rotate around the main shaft, the wheel shock absorber 2 drives the outer steel ring 1.2 and the tire 1.1 to produce a rotary motion, and the tire 1.1 is in contact with the ground , to generate forward or backward driving force to complete the driving requirements of the vehicle.

[0082] The axle shaft 5 and the main shaft of the driving motor 3 are fixedly connected, and can not rotate relatively in the course of work, and the shell of the driving motor 3 can rotate around the axle shaft 5 . The casing of the drive motor 3 forms a connection with the steel ring 1.2 through several wheel shock absorbers 2, so that the wheels can be driven to rotate.

[0083] Wheel system braking method:

[0084] The brake disc 1.3 i...

Embodiment 3

[0103] This embodiment provides a vehicle, the wheels of which use the electric wheel system integrated with shock absorption and power generation described in Embodiment 1. Through the electric wheel system, functions such as driving, shock absorption, power generation, braking, and damping adjustment of the vehicle are realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com