Device for damping vibration of transmission

A damper and transmission technology, applied in the field of vibration devices, can solve problems such as uneven shifting operation, increase of input shaft resistance torque, and adverse effects on operation synchronization, so as to increase the degree of freedom, eliminate vibration and vibration noise, and prevent Effect of excessive increase in overall length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, an exemplary embodiment of a device for damping vibration of a rotating shaft of a transmission (ie, a vibration damper) will be described with reference to the accompanying drawings.

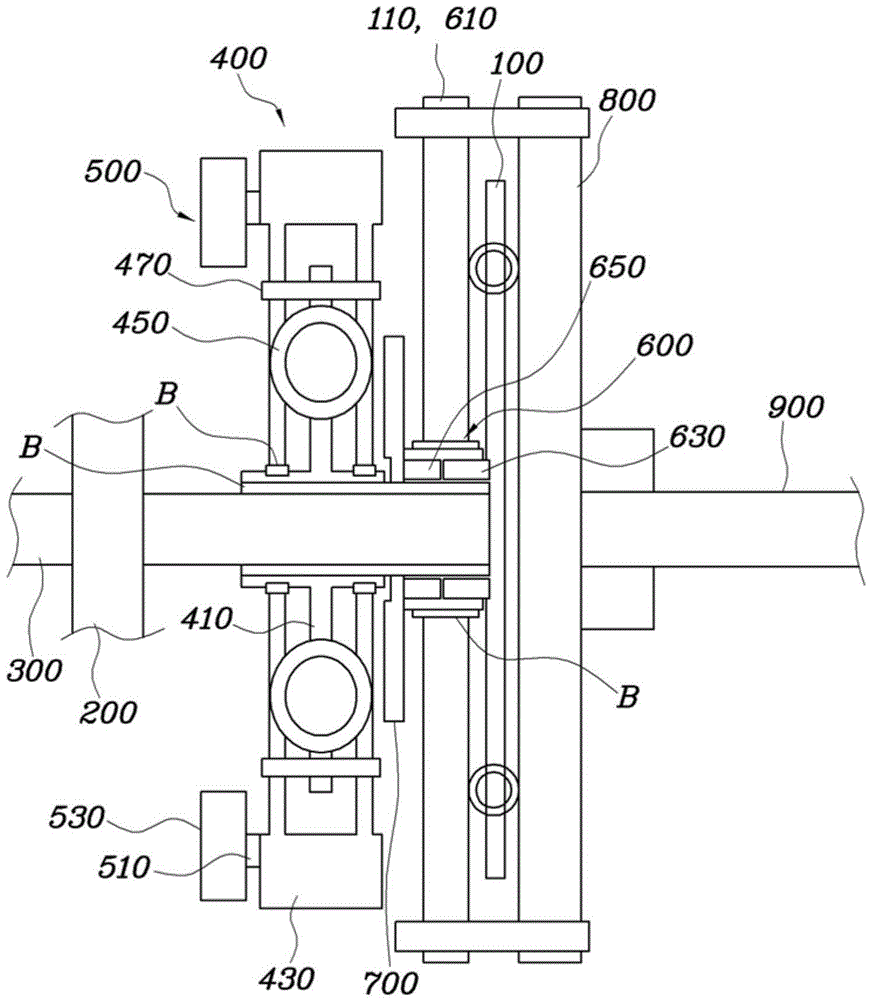

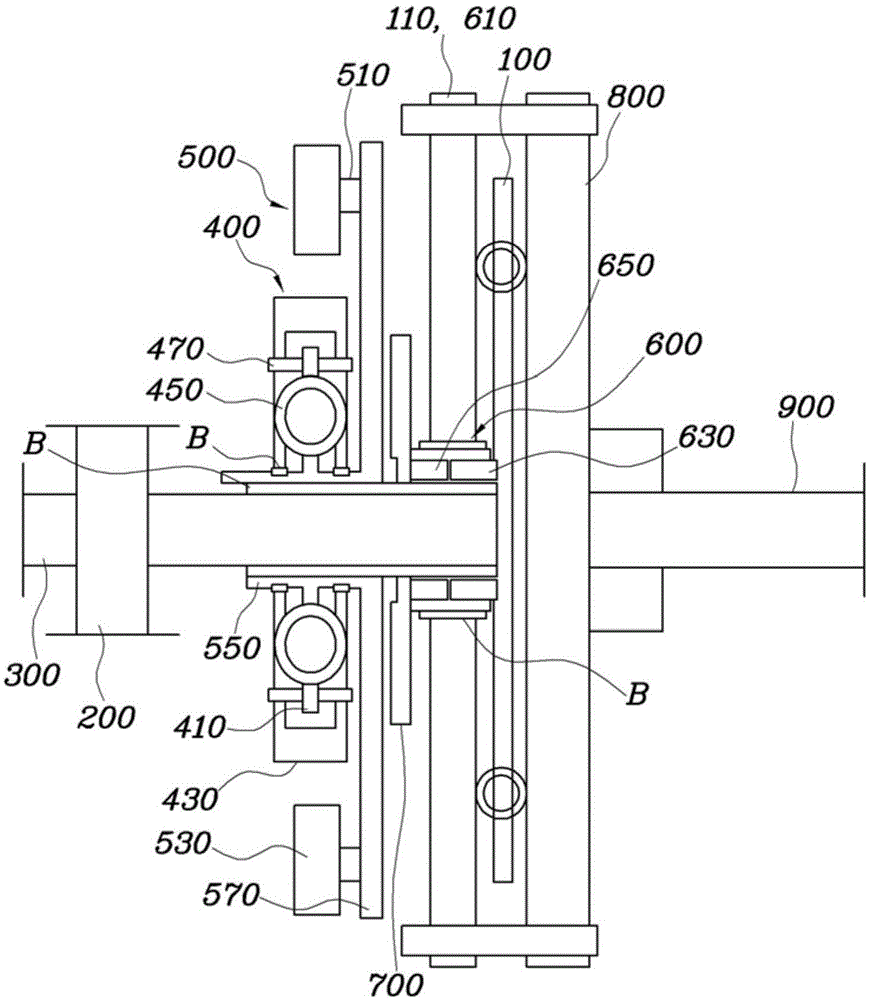

[0022] figure 1 is a view of a series connection of vibration damping devices of a transmission rotary shaft according to an embodiment of the present invention, figure 2 is a view of the parallel connection of the vibration damping device.

[0023] The device for damping vibration of the transmission rotating shaft (ie, the vibration damping device) includes: an input shaft damper (ISD) 400 rotatably disposed around the transmission rotating shaft 300 between the clutch 100 and the transmission housing 200 ; a centrifugal pendulum assembly (CPA) 500, which is rotatably connected to the ISD to damp the pulsation of the ISD; and a bi-directional actuator 600, which is disposed between the input shaft damper 400 and the clutch 100, for 400 and clutch 100 apply force bi-dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com